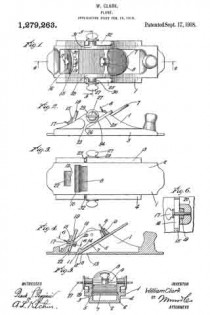

No. 1,279,263 – Plane (William Clark) (1918)

UNITED STATES PATENT OFFICE.

_________________

WILLIAM CLARK, OF NEW YORK, N. Y., ASSIGNOR OF ONE-HALF

TO JOHN T. HILBERT, OF LONG ISLAND CITY, NEW YORK.

PLANE.

_________________

1,279,263. Specification of Letters Patent. Patented Sept. 17, 1918.

Application filed February 19, 1918. Serial No. 218,115.

_________________

To all whom it may concern:

Be it known that I, WILLIAM CLARK, a citizen of the United States, and a resident of the city of New York, Long Island City, borough of Queens, in the county of Queens and State of New York, have invented a new and Improved Plane, of which the following is a full, clear, and exact description.

This invention relates to wood working implements and particularly to a plane capable of a plurality of adjustments to accomplish different purposes, and has for an object the provision of such a structure as to be quickly and easily adjusted to respond to the different requirements.

Another object of the invention is to provide a plane in which the main cutting blade is held in runways while other implements may be clamped on different sides provided therefor so as to coact with the central blade, or act independently thereof.

A further object of the invention is the provision of a plane having a central guide for a central blade, a pair of side guides for cutting tools of different kinds, a front guide and offset portions on the sides for allowing the side implements to act as beading tools, grooving tools, and the like.

A still further object, more specifically is the provision of a single skeleton or frame and a plurality of tools and clamps associated therewith whereby a single frame can be used with the different tools necessary for substantially all requirements of a carpenter.

In the accompanying drawing:

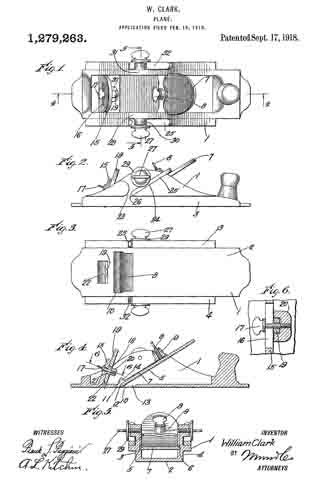

Figure 1 is a top plan view of a plane disclosing an embodiment of the invention.

Fig. 2 is a side view of the plane shown in Fig. 1.

Fig, 3 is a bottom plan view of the plane shown in Fig. 1.

Fig. 4 is a longitudinal vertical section through the plane shown in Fig. 1, same being taken on line 4–4.

Fig. 5 is a transverse sectional view through Fig. 1 on line 5–5.

Fig. 6 is a fragmentary detail sectional view through Fig. 4 on line 6–6.

Referring to the accompanying drawing by numerals, 1 indicates a frame or skeleton of a plane, which plane is provided with a smooth bottom 2 and offset portions 3 and 4, said offset portions being utilized when one of the side tools is being used as a beading tool, or when a piece of material is being specially formed. The body 1 is provided with a pair of grooves 5 and 6 in which the blade 7 is slidingly positioned, said blade being clamped in any desired adjusted position by a thumb screw 8 which extends through a transverse bar 9 connected at the ends to the body 1 or formed integral therewith. The blade 7 extends for almost the full width of the bottom 2 and projects through a comparatively large opening 10, and the grooves 5 and 6 causing the blade to extend through the opening in such a manner, as there will be provided a passageway 11 in front of the cutting edge 12 of the blade and a passageway 13 at the rear of the blade. The side walls of frame 1 are cut away at 14 which is opposite the cutting edge 12 whereby chips, shavings and the like cannot become wedged beneath the blade or between the blade and the side walls. As the blade 7 moves upwardly and downwardly in the guiding grooves 5 and 6 the cutting edge is always true in respect to the bottom 2 so that a proper shaving will be produced when this blade is in use.

At the front part of the frame 1 a transverse plate or section 15 is provided which may be independent of the frame or formed integral therewith, said section having a slot 16 extending transversely of the body 1 as shown more particularly in Fig. 1. A thumb screw 17 extends through this slot and also through the slot 18 in the tool 19, slot 18 extending at right angles to slot 16. A nut 20 is normally positioned on the end of screw 17 so that when the tool 19 has been properly adjusted vertically and also horizontally thumb screw 17 may be tightened and tool 19 clamped in place. The nut 20 may be of the ordinary type, but is preferably provided with overhangin shoulders 21 projecting on each side of the tool 20. The tool 19 may be used for providing a central bead, rabbit, or any other desired structure and preferably extends through an aperture in the bottom 2 centrally thereof as shown in Fig. 4 so that there will be a passageway both in front and back of the tool as well as on both sides, as the aperture 22 usually extends for the full width of the section 15 though the tool may be positioned so as to operate substantially at any point in front of the blade 7. On one side of the frame 1 is positioned the offset 3 which merges into an opening 23 whereby there is provided a shoulder 24 for receiving a tool 25. Tool 25 may be an ordinary blade with a straight edge or may be a beading tool, or a tool of any preferred kind. Regardless of the form of the cutting edge 26 on tool 25 said tool is held in place by a thumb screw 27 threaded into the side wall 28 of frame 1, said thumb screw having a thumb engaging member and a flange 29 overlapping the tool 25, but preferably not overlapping shoulder 24 whereby the tool is pressed tightly against the wall 28 and held in position while in operation. Wall 28 is provided with a boss 30 spaced a short distance above the shoulder 24, said shoulder being spaced a sufficient distance for allowing the tool 25 to freely slide, but will prevent any twisting motion thereof.

On the opposite side of the frame 1 and associated with the wall 31 and the offset 4 is a tool 32 and associate parts of identical construction with tool 25 and associate parts so that no additional description will be necessary.

What I claim is:

1. A plane comprising a frame having a pair of upstanding side members, said side members having facing guideways for receiving a planing tool, means for holding said planing tool in said guideways, each of said side members being provided with a shoulder for receiving auxiliary tools, and a threaded lug, a clamping screw threaded into each of said threaded lugs, each of said clamping screws having an enlargement overlapping the tools supported by said shoulders for clamping the tools in place.

2. A plane comprising a frame having a smooth bottom and a pair of upstanding sides, said sides having facing inclined grooves for receiving a planing tool, said bottom having a notch at the base of said grooves merging into said grooves, and means for locking a planing tool in said inclined grooves.

3. A plane comprising a frame formed with a smooth bottom and a pair of upstanding sides, the juncture of said sides and said bottom being formed with offsets or shouldered portions, the outer surface of said shouldered portions being parallel with said bottom, means for clamping a cutting tool so as to extend through said bottom and operate as an ordinary plane, and means for clamping a tool against each of said sides so as to project through the outer surface of said shouldered portions.

4. A plane comprising a frame having an opening in the bottom, means for holding a planing tool so as to extend through said opening, an upstanding transversely slotted member connected with said frame in front of said opening, and means adjustable along said slot and extending therethrough for clamping a tool against said upstanding member.

5. A plane comprising a frame having a centrally arranged seat for a comparatively large planing tool, side seats adjacent said central seat for side planing tools, a front tool seat arranged centrally, and independent means adjacent each of said seats for clamping tools on the respective seats.

WILLIAM CLARK.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________