No. 195,481 – Improvement In Bench-Planes (Henry M. Clark) (1877)

UNITED STATES PATENT OFFICE.

_________________

HENRY M. CLARK, OF NEW BRITAIN, CONNECTICUT.

IMPROVEMENT IN BENCH-PLANES.

_________________

Specification forming part of Letters Patent No. 195,481, dated September 25, 1877; application filed August 6, 1877.

_________________

To all whom it may concern:

Be it known that I, HENRY M. CLARK, of New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Devices for Adjusting Plane-Irons, of which the following is a specification:

My invention consists in the employment of a transverse slide. provided with an inclined slot and operating screw, and also in the peculiar construction of the parts, as hereinafter described.

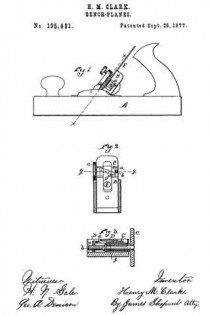

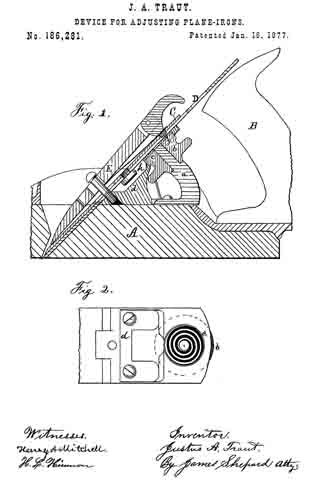

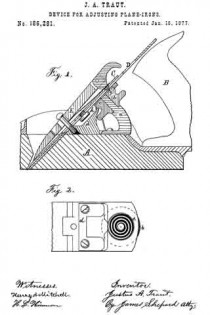

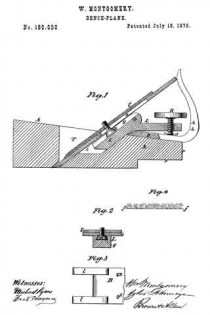

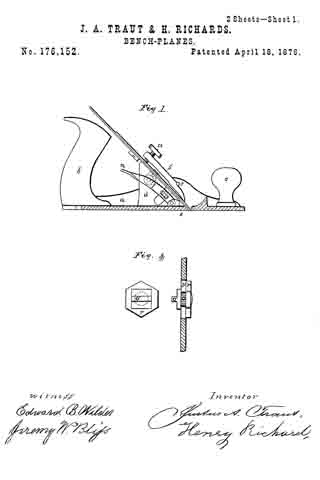

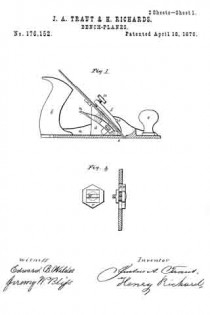

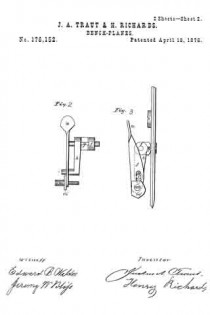

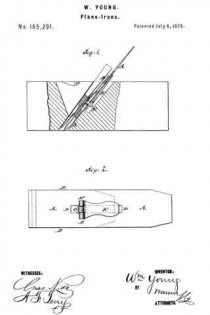

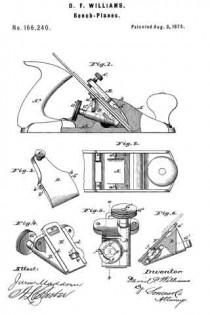

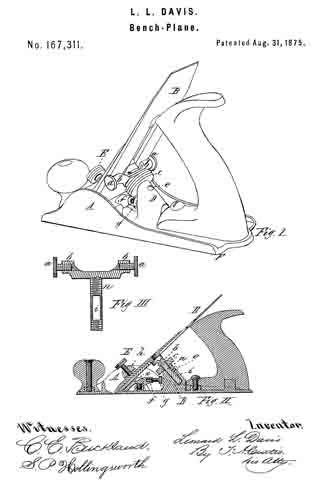

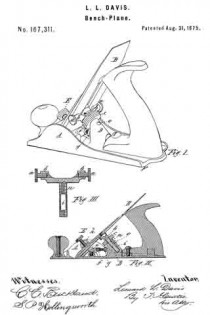

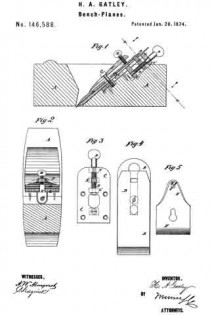

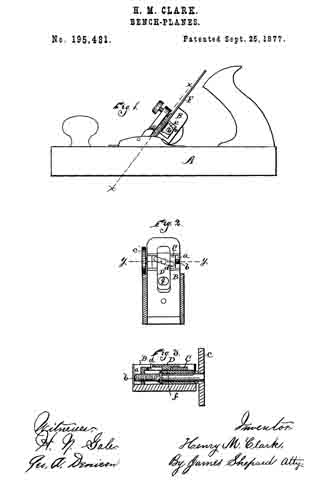

In the accompanying drawings, Figure 1 is a side elevation of a device for adjusting plane-irons which embodies my invention. Fig. 2 is a sectional view of the same on line x x of Fig. 1, with cap and plane-iron removed, the same being viewed from a point at right angles to the face of the frog; and Fig. 3 is a transverse section of the same on line y y of Fig. 2.

The stock A may be any of the ordinary kinds, and the frog B can be secured thereto in any proper manner. Transversely to the frog B is a recess or depression, a, which is made shallow on the right-hand side of the frog and deep on the left-hand side of the frog. The body of a screw, b, passes through the solid metal of the frog just under the shallow portion of the depression a, and the screw proper extends into the deeper portion of said depression.

The outer end of the screw b is provided with a suitable head or handle, c, for operating said screw, and it is prevented from longitudinal movement by shoulders at each end of its bearing in the frog.

Fitted to move in the depression a is a slide, C, having an inclined slot, d, and threaded lug e, through which lug the screw b passes. By turning the screw the slide may be moved endwise either to the right or left, as may be desired.

Another slide, D, is fitted to slide longitudinally in a recess in the frog B, and the upper end of this longitudinal slide is provided on its under side with a projecting pin or stud, f Fig. 3, also indicated by broken lines in Fig. 2, which pin or stud engages the side walls of the inclined slot in the slide C. In the lower end of the longitudinal slide is an orifice to receive the head of the ordinary cap-screw, which orifice, g, Fig. 2, may be elongated somewhat from right to left, so that the plane-irons F may be moved sidewise a little to bring the end of the cutting-bit square with the face of the stock.

When the transverse slide is moved endwise, by means of the operating screw, the side walls of the inclined slot d engage the pin or stud f and move the longitudinal slide and plane-irons.

If the slide C is moved to the right, the Iongitudinal slide D is forced downward, carrying the plane-irons with it, and, if moved to the left, the plane-irons are drawn upward into the stock with said slide.

If desired, instead of connecting the longitudinal slide to the plane-irons through means of the ordinary cap-screw, a stud may be attached directly to the cutting-iron, and received in the orifice at the lower end of the longitudinal slide.

My adjustment is very cheaply constructed, and adjusts the plane-iron with ease and smoothness.

I claim as my invention —

1. In a device for adjusting plane-irons, the transverse slide, provided with inclined slot and operating mechanism for moving said slide transversely to the plane-iron, substantially as described, and for the purpose specified.

2. In a device for adjusting plane-irons, the screw b, set transversely to the frog, and secured from longitudinal movement, in combination with the incline slotted slide, provided with threaded lug e, which receives the adjusting-screw, substantially as described, and for the purpose specified.

HENRY M. CLARK.

Witnesses:

T. A. CONKLIN,

JAMES SHEPARD.