No. 195,480 – Improvement In Circular Planes (Henry M. Clark) (1877)

UNITED STATES PATENT OFFICE.

_________________

HENRY M. CLARK, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO THE STANLEY RULE AND LEVEL COMPANY, OF SAME PLACE.

IMPROVEMENT IN CIRCULAR PLANES.

_________________

Specification forming part of Letters Patent No. 195,480, dated September 25, 1877 application filed August 6, 1877.

_________________

To all whom it may concern:

Be it known that I, HENRY M. CLARK, of New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Circular Planes, of which the following is a specification:

My invention consists of a connecting mechanism for the two ends of the flexible bottom of a circular plane, so that they necessarily move together, in combining therewith a single operating device, in the peculiar construction of parts, and in their combination, as hereinafter described.

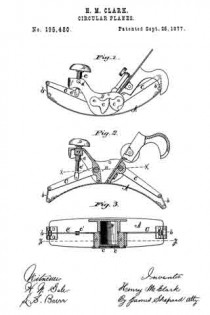

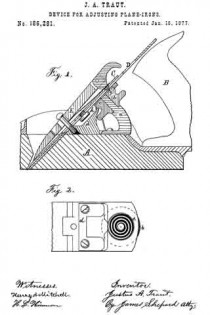

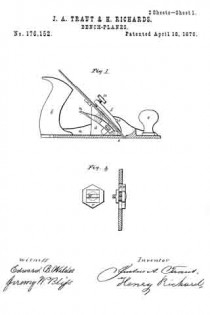

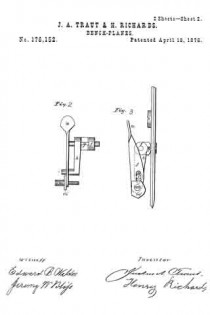

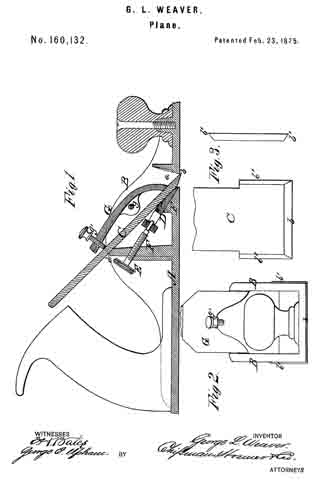

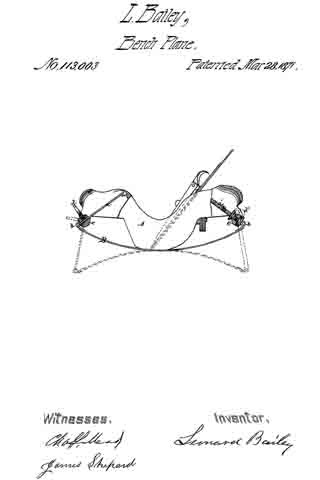

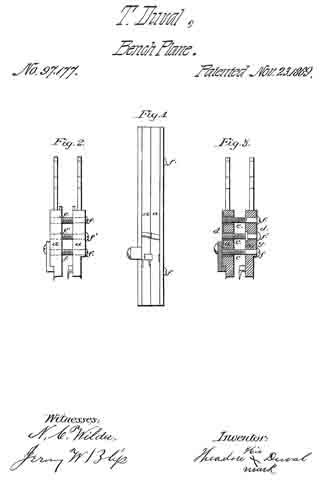

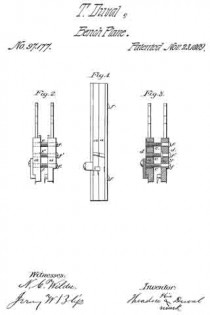

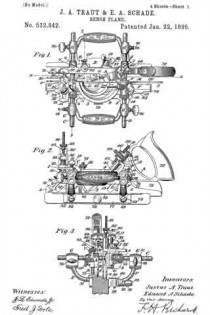

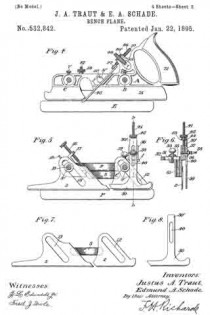

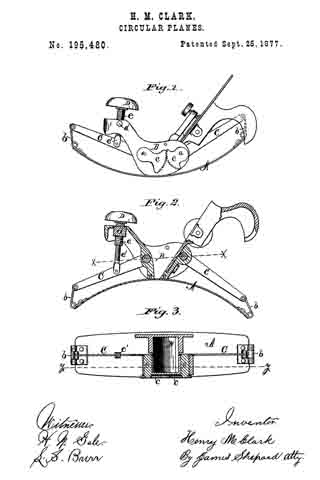

In the accompanying drawings, Figure 1 is a side elevation of a circular plane, which embodies my invention. Fig. 2 is a vertical section of the same on line y y of Fig. 3, and Fig. 3 is a horizontal section of the same on line x x of Fig. 2.

In Fig. 1 the flexible bottom A is set in a convex position for dressing a concave surface, and in Figs. 2 and 3 it is set in a concave position for dressing a convex surface.

Circular planes having a flexible bottom and mechanism for holding the same when set in various circles are old; but, so far as I know, the two ends of the flexible bottom have never before been so connected as to necessitate their simultaneous movement. These prior planes had no mechanism for moving the ends of the flexible bottom, but only mechanism for holding the ends in place when moved by hand; and these holding mechanisms were entirely independent of each other, so that unless great care was taken in setting the bottom, one end would be bent to conform to one sized circle and the other end to conform to a circle of a different size.

The object of my invention is to adjust the flexible bottom more conveniently than heretofore, and to always adjust both ends to the same circle.

The flexible bottom A is secured to the stock B by screws taking into the stock at each side of the throat, in the usual manner of securing the same in circular planes.

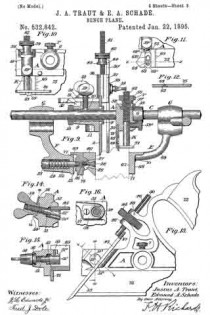

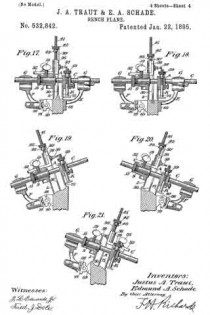

At one side of the stock B short shafts a a are secured in proper bearings, so as to partially rotate therein. On the inner ends of said shafts a a, and in the middle of the stock B, rocking levers C C are rigidly secured, so as to rotate with said shafts. The outer ends of the rocking levers C C are connected to the ends of the flexible bottom A by means of the links b b.

On the outer ends of the shafts a a, rigidly secured, are segment-gears c c, which mesh into each other and necessitate the movement of one shaft with its fellow.

Inasmuch as the rear end of the flexible bottom is longer than its front end, and describes a larger circle in bending, the segment-gear on the front or short end is made larger than the segment-gear on the long end, in order to cause the latter to move enough faster than the former to compensate for the difference in the size of the circle described by the two ends of the flexible bottom.

In the front end of the stock B there is a rocking block or nut, d, which receives the adjusting-screw e, surmounted by a suitable knob or handle, D. The screw e is also provided with an internal thread, running in the opposite direction from that of its external thread, which internal thread receives the adjusting-screw e’, the lower end of which is connected by a pin or other jointed connection to one of the levers.

By turning the adjusting-screw e e’, the lever C, to which it is connected, is either depressed or lowered, according to which way the screw is turned, thereby partially rotating the shaft a. The segment-gear on the outer end of the shaft, meshing into a like gear on its fellow shaft, carries the opposite lever with the one connected to the screw, and the ends of the flexible bottom being connected by the links to said levers, as shown, must necessarily move together; and if the size of the segment-gears is properly arranged in relation to the circles described by both ends of the flexible bottom, said ends will both of them always be bent to conform to the same circle under all the various adjustments which they undergo.

The double screw e e’ is merely for the purpose of increasing the motion of the lever, and may, if desired, be omitted, and a single screw substituted therefor.

Other means might be employed for moving the levers or securing them in place without changing the portion of the invention which relates to moving both ends of the flexible bottom together.

If desired, the segment-gears might be separated a little and a worm placed between them, so as to engage the teeth thereof, whereby turning the worm will simultaneously move both segment-gears, levers, &c., in either of which modifications a single handle only has to be manipulated to operate both ends of the flexible bottom.

I claim —

1. In a circular plane, the combination of the flexible bottom A and mechanism, substantially as described, connecting its two ends, for necessitating their simultaneous movement, substantially as described.

2. In a circular plane, the combination of the flexible bottom A, mechanism, substantially as described, connecting its two ends and necessitating their simultaneous movement, and a single adjusting or operating handle, substantially as described, and for the purpose specfiied.

3. In a circular plane, the combination of the stock B, flexible bottom A, link b, rocking lever C, and adjusting-screw e, substantially as described, and for the purpose specified.

4. In a circular plane, the combination of the flexible bottom A, links b b, levers C C, shafts a a, and sement-gears c c, substantiallly as described, and for the purpose specified.

HENRY M. CLARK.

Witnesses:

T. A. CONKLIN,

JAMES SHEPARD.