No. 483,294 – Spokeshave (Edward D. White) (1892)

UNITED STATES PATENT OFFICE.

_________________

EDWARD D. WHITE, OF HARTFORD, CONNECTICUT.

SPOKESHAVE.

_________________

SPECIFICATION forming part of Letters Patent No. 483,294, dated September 27, 1892.

Application filed January 22, 1892. Serial No. 418,975. (No model.)

_________________

To all whom it may concern:

Be it known that I, EDWARD D. WHITE, of Hartford, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Spokeshaves, of which the following is a full, clear, and exact description, whereby any one skilled in the art can make and use the same.

The special object of my invention is to provide a tool belonging to the class of spoke-shaves that shall be particularly adapted to cutting leather, although it is equally adapted for other uses; and to this end it consists of the details of the several parts making up the spokeshave as a whole and in their combination, as more particularly hereinafter described, and pointed out in the claims.

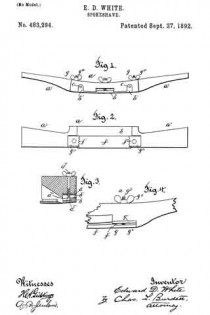

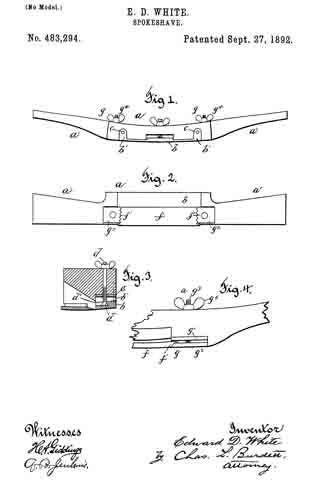

Referring to the drawings, Figure 1 is a detail front view of a spolreshave embodying my invention. Fig. 2 is a detail view of the under side of the spokeshave. Fig. 3 is a detail view, in cross-section, through the spokeshave, illustrating the method of supporting and adjusting the throat-piece. Fig. 4 is a detail rear view of a portion of a spokeshave embodying my invention.

In the accompanying drawings, the letter a denotes the body part of the spokeshave, made usually of wood and provided at the opposite ends with handles a’, by means of which the tool is held in working.

The letter b denotes a throat-piece located on the under side of the body part of the shave and connected to it by means of screws c, that pass through the upturned arms b’ at opposite ends of the throat-piece. These arms are preferably located in sockets formed in the body part of the shave and are secured by means of these screws or bolts, that pass through holes in the upper ends of the arms, the hole being slightly larger in diameter than the supporting bolt or screw in order to allow the throat-piece to have a swinging movement on such supports. In order to provide for this adjusting movement of the throat-piece, the edge of which extends lengthwise of the blade and immediately in front thereof, the head d’ of a bolt d engages a socket d2, formed in the upper part of the throat-piece, the bolt having a threaded portion extending through the nut e, that is secured to the body part of this spokeshave. The upper end of this bolt is provided with a thumb-nut or suitable handle, by means of which the bolt may be rotated in such manner as to change the position of the front edge of the throat-piece, so as to regulate the width of the opening between the cutting-edge of the blade and the edge of the throat-piece. The blade f is removable and adjustable, and it is secured to the body part of the spokeshave by means of clamp devices, that are located at the opposite ends of the blade. These clamp devices g comprise a bed-piece g’, against which the back part of the blade rests, and which may be formed by the surface of the spokeshave when such part is of metal, but when of wood are preferably formed by pieces of metal located in a suitable socket, and a holding part g2, that is connected by means of a bolt g3 with a nut g4, that fits on the threaded upper end of the bolt that extends through the body of the shave. The ends f’ of the blade proper are beveled and are made irregular, preferably by serrating such edges or forming a number of teeth that are engaged by corresponding teeth formed in the beveled edge of the clamp-plate. These serrations or indentations have a double function, taken in connection with the bevel of the edge: first, to provide for the adjustment of the blade in the direction of the throat-piece, and, next, to enable the blade to be removed and renewed after grinding or replaced by a new blade. The indentations or serrations are made sufficiently close together to permit of any needed degree of forward adjustment of the blade to compensate for the wear of the cutting-edge.

The cutting-blade in my improved spoke-shave is both renewable and adjustable and is clamped by positive clamping means formed to prevent the blade from slipping when the spokeshave is in use, and the blade being of a single piece, without any projecting parts at right angles to the blade, which are needed in old forms of spokeshave, may be ground on any grindstone without regard to its width, and such a blade is therefore readily sharpened. Two or more blades may be provided, so that in case the spokeshave is being used at a distance from a shop where such repairs may be made a new and sharp one may be readily inserted in the place of one that by use has become broken or dulled.

A particular advantage of the adjustable throat-piece is that the spokeshave can be adjusted to out a shaving of any desired thickness, and the throat-piece may also be so adjusted as to project beyond the cutting-edge, and serves as a guard for it. When the throat has become clogged by shavings, it is readily cleared by simply enlarging the opening by a simple turn of the adjustable bolt.

I claim as my invention —

1. In a spokeshave, in combination with the body part, the adjustable throat-piece comprising a flat portion, the upturned arms, the fastening means whereby the throat-piece is loosely secured to the body part of the spokeshave, and the clamp-screw whereby the throat-piece is adjusted, the removable blade having the beveled and serrated ends, and the clamp devices having the corresponding beveled and serrated edges, all substantially as described.

2. In a spokeshave, in combination with the body part, an adjustable throat-piece comprising a flat portion, the upturned arms having sockets, the bolt or like part smaller in diameter than said sockets for loosely securing the throat-piece to the body portion of the spokeshave, the clamp-screw whereby the throat-piece is adjusted, the removable blade having the beveled and serrated ends, and the clamp devices having the corresponding beveled and serrated edges, all substantially as described.

3. In a spokeshave, in combination with the body part, the adjustable throat-piece comprising a flat portion, the upturned arms, the fastening means whereby the throat-piece is loosely secured to the body part of the spokeshave, the adjusting-screw having its lower end engaging a socket in the throat-piece and a threaded portion engaging the body of the spokeshave, whereby said adjusting-screw has a vertical movement, the removable blade having the beveled and serrated ends, and the clamp device having the corresponding beveled and serrated edges, all substantially as described.

4. In a spokeshave, in combination with the body part, the adjustable throat-piece comprising a flat portion, the upturned arms, the fastening means whereby the throat-piece is loosely secured to the body part of the spokeshave, the adjusting-screw having its lower end engaging a socket in the throat-piece and a threaded portion engaging a nut located on the body of the spokeshave, the nut, the means for turning the adjusting-screw, the removable blade having the beveled and serrated ends, and the clamp devices having the corresponding beveled and serrated edges, all substantially as described.

EDWARD D. WHITE.

Witnesses:

HARRY S. POWERS,

EDWARD J. PEARSON.