No. 285,546 – Bench-Plane (Leonard Bailey) (1883)

UNITED STATES PATENT OFFICE.

_________________

LEONARD BAILEY, OF HARTFORD, CONNECTICUT.

BENCH-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 285,546, dated September 25, 1883.

Application filed July 11, 1883. (No model.)

_________________

To all whom it may concern:

Be it known that I, LEONARD BAILEY, of Hartford, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Planes; and I do hereby declare that the following is a full, clear, and exact description thereof, whereby a person skilled in the art can make and use the same, reference being had to the accompanying drawings, and to the letters of reference marked thereon.

Like letters in the figures indicate the same parts.

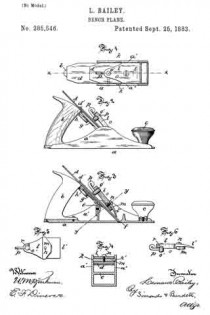

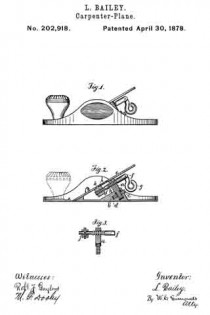

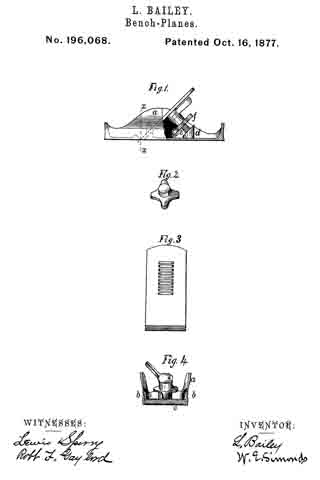

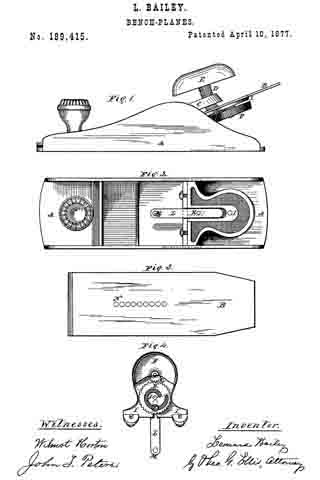

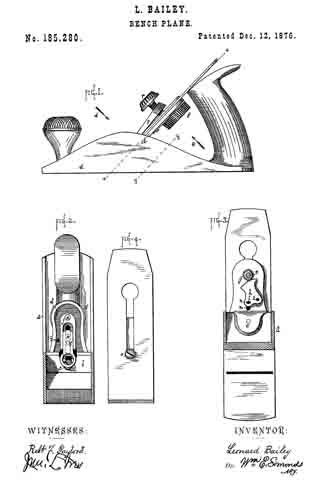

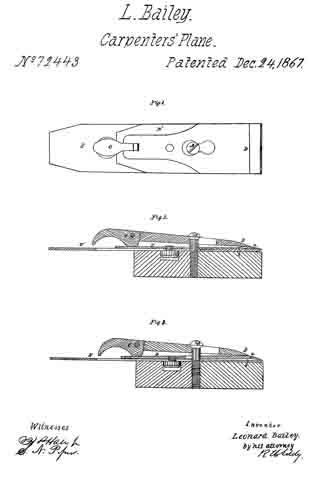

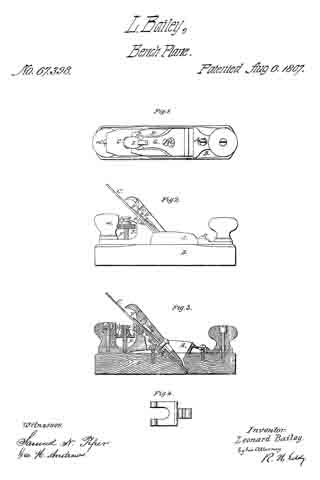

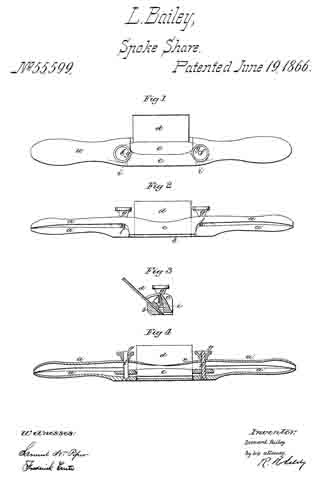

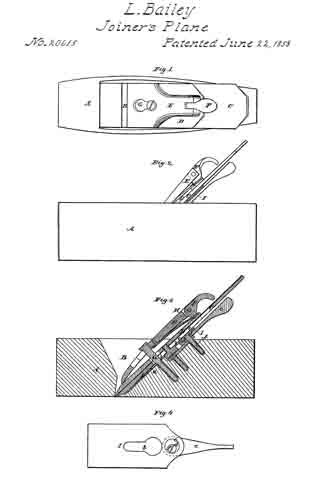

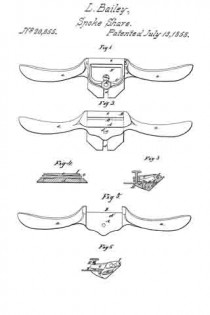

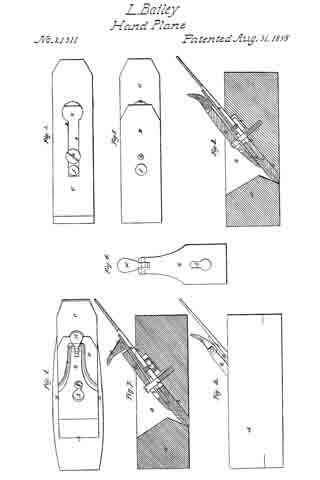

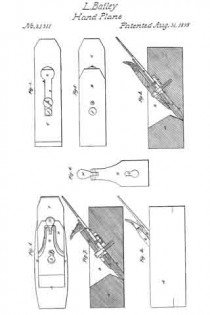

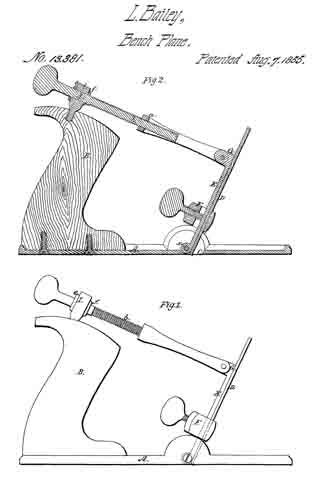

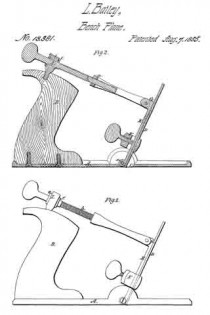

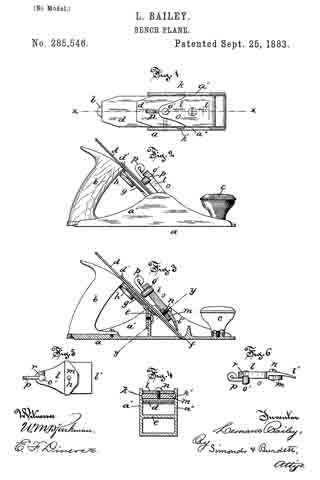

Figure 1 is a plan view of the upper side of the plane in a line at right angles to the plane of the iron parts broken away. Fig. 2 is a side view of a plane having my improvement. Fig. 3 is a view in central vertical longitudinal section of same on line x x of Fig. 1. Fig. 4 is a view in cross-section on plane denoted by line y y of Fig. 3. Fig. 5 is a detail bottom view of my improved clamp. Fig. 6 is a detail side view of same.

My invention relates to the class of devices used for holding the cutting-iron of a plane in place in the body in such manner as to allow of the ready adjustment of the iron lengthwise in the usual manner.

It consists in the special combination and arrangement ofthe parts making up the clamping device, and in the method of fastening it in the plane-body.

In the accompanying drawings, the letter a denotes the plane-body as a whole, formed of any ordinary material, as iron; b and c, handles for grasping and using the plane; d, a cutting-iron of ordinary form arranged upon a bed, e, so as to be protruded from the usual mortise, f, by means of any slow-motion device, as a series of intermeshing cog-wheels, g, operated by means of the thumb-screw h.

There is nothing new or original with me in the parts described thus far, and no further description is needed for one skilled in making or using planes.

In the style shown the plane-body a is of iron, with the upright side flanges, a’ a”, and on the inner side of each of these danges the corresponding mortises, k k’, are made substantially parallel in direction with the plane of the cutting-iron, and a short distance above or in front of its upper surface.

The letter l denotes the clamp-plate, having the foot l’, adapted to bear upon the face of the cutting-iron, or on the cap-iron d’, placed just over and upon it, and having arranged upon its under side, just in front of a transverse shoulder, the laterally-projecting arm m, adjustably attached to the clamp-plate by means of the screw n. This arm is so arranged that its opposite ends fit into and move in the mortises in the flanges, and form the fulcrum on which the clamp works in fastening the irons in place. In the upper end of the clamp-plate is placed a clamp, o, consisting of a shaft, o’, which is rotarily secured with its lower end bearing upon the cutting-iron about on its center line, and bears the lever p, which extends beyond the edges of the clamp-plate, and operates in connection with the face-cam r on its under side.

The particular object of my invention is to secure a firm and even bearing for the foot of the clamp upon the irons under it, to provide simple means for regulating the pressure of the clamp at will, and yet have it constant for any given set of irons, and have all the requisite parts simple in form, combination, and operation.

The arm m is loosely attached to the clamp-plate, so that the foot of the latter may find a bearing for its whole length on the iron under it, and the ends of the arm at the same time bear upon the sides of the mortises when the clamp-plate is clamped.

The clamp-plate and arm may be connected, so that the arm will tilt or work by means of a rivet or short bolt; but I prefer to use the screw herein shown and described, as I can then adjust the amount of pressure put upon the parts in clamping the irons in place, and vary it as the parts wear, or for different irons adapted to the same body.

In the drawings the clamp is shown as locked; but it is unlocked by turning the lever about ninety degrees to the position shown in dotted lines in Fig. 1, as this allows the shaft to slip upward through the clamp as the lever moves along the cam. By pulling straight back, the clamp may be removed as the arms slide out of the mortises. By means of the screw n the arm is raised or lowered with respect to the clamp-plate and the binding force of the shaft-lever and cam is adjusted.

I am aware that clamp-plates bearing cam devices for fastening the irons in place are not new, and these I do not broadly claim.

I claim as my invention —

1. In combination, the plane-body having the side flanges with inward-facing mortises, and the clamp-plate bearing the loosely-attached arin, adapted to operate in said mortises and the clamp, all substantially as described.

2. In combination, the mortised plane-body, the clamp-plate bearing the adjustable arm attached thereto by the centrally-located screw, and having the face-cam, and the rotary shaft bearing the lever operating on said cam, all substantially as described.

3. In combination, in a plane having the lateral mortises or bearings, the clamp-iron bearing the loosely-connected arm arranged transversely of the clamp-iron, and adjacent to the arm, the shoulder, or its equivalent, whereby the arm is held against rotation, all substantially as described.

LEONARD BAILEY.

Witnesses:

CHAS. L. BURDETT,

E. F. DIMOCK.