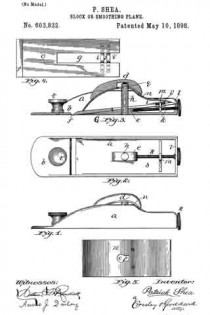

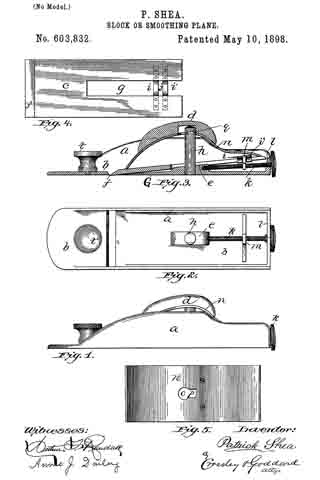

No. 603,832 – Block Or Smoothing Plane (Patrick Shea) (1898)

UNITED STATES PATENT OFFICE.

_________________

PATRICK SHEA, OF BOSTON, MASSACHUSETTS.

BLOCK OR SMOOTHING PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 603,832, dated May 10, 1898.

Application filed September 20, 1897. Serial No. 652,271. (No model.)

_________________

To all whom it may concern:

Be it known that I, PATRICK SHEA, of Boston, (Dorchester,) in the county of Suffolk and State of Massachusetts, have invented certain new and useful Improvements in Block or Smoothing Planes, of which the following is a description sufficiently full, clear, and exact to enable those skilled in the art to which it appertains or with which it is most nearly connected to make and use the same.

This invention relates to woodworkers’ planes generally, and particularly to metal block or smoothing planes.

It is the object of the invention to provide such improvements in articles of manufacture of the kind mentioned as will enable the bit or plane-iron to be supported at but a slight pitch or angle relatively to the sole or face of the plane, so as that it may better perform some functions than if it were set at the usual or common angle.

It is also the object of the invention to provide improved means for adjusting the plane-iron or bit, so that its depth of cut may be regulated with the utmost nicety.

It is, furthermore, the object of the invention to provide improved means for holding the plane-iron down upon its bed or seat, which means shall be simple in and economical of construction and serviceable and efficient in the highest degree.

To these ends my invention consists of the improvements which I will proceed to describe in detail, and then set forth with particularity in the appended claims.

Reference is to be had to the annexed drawings, and to the letters marked thereon, forming a part of this specification, the same letters designating the same parts or features, as the case may be, wherever they occur.

Of the drawings, Figure 1 is a side elevation of a metallic block-plane embodying my improvements. Fig. 2 is a plan view of the same, the bow-spring and toat being omitted. Fig. 3 is vertical longitudinal sectional view of the same. Fig. 4 is a plan view of the plane-bit detached. Fig. 5 is a bottom view of the bow-spring used to hold the bit down upon its bed and to serve also as the toat to the plane.

In the drawings, a designates the stock or frame of the plane, which, as herein shown, it is proposed to construct of metal, though it may be made of other material.

b is the sole or base, which is provided with sides or walls a and a rear wall or cross-

piece l.

c is the bit or plane-iron.

t is the “horn.”

d is the toat.

In carrying out my invention I provide a projection e on the upper side of the base G, provided with a vertical perforation to receive a stud h.

The bit is adapted to travel on inclined shevels or shoulders along the sides a of the stock, extending from the cross-piece l to the throat, and is formed in its longitudinal central rear portion with a slot g sufficiently wide to have the stud h and projection e operate therein when the bit is moved back and forth. Near the rear end of the bit there are two cross-bars i i’ secured to the bit, so as to bridge, as it were, the slot g and leave a space j between said cross-bars. It would serve my purpose just as well, however, to make the cross-bars i i’ an integral part of the bit.

k is a bit-adjusting screw threaded throughout nearly its length and arranged to turn in a hole formed in the vertical rear flange l of the bit-stock and at its inner end to be guided in a hole formed in the rearward part of the projection e. Neither of the said supports for the screw are screw-threaded, but are simply plain bearings for the latter.

Upon the screw k there is arranged a traveler on, having a screw-threaded hole formed therethrough to receive the shank of the screw k. The said traveler m extends up between the bridge-pieces i i’ of the bit in such a manner that when the screw is turned the traveler will be moved to and fro thereon, and as a consequence will move the bit longitudinally with it and adjust the bit in the mouth of the base of the plane, so as to make it take a deeper or shallower cut, as may be desired.

n designates the bow spring or holder, which is a piece of sheet metal bent in cross-section in the form of a bow, as is best represented in Fig. 3, so that its front end may rest upon the forward end of the bit and its rearward end bear upon the rear end of the same. Upon the bow-spring n, the toat d is supported, as shown.

In the central portion of the bow-spring there is formed a hole o, backward from which there extends a narrowed slot p, and in the upper end of the stud h, on opposite sides thereof, there are formed slots q, so that after the bit may have been put in place upon its bearings and properly connected with its adjusting means the bow-spring may be placed in position upon the bit, so that the upper end of the stud h, may extend through the hole o, and then by bearing down on the spring and moving it forward the sides of the slot p may take into the slots q of the stud and not only hold the spring in place, so that the toat or handle d may be employed in moving the plane, but so also as that the bow-spring may press and hold the bit down in its proper working position.

Inasmuch as in the operation of the plane the effort to move it back will be but slight and substantially all of the appreciable energy will be exerted forward, the bow-spring and toat will be held securely in place.

In addition to supporting the bit or plane-iron in position so as to render it most efficient in operation, as I have before described, my adjusting means for the bit have been found very efficient and simple, not liable to be disturbed in the usual operation of the plane, and effective in operating the bit to adjust it with the utmost nicety, and to do this in a manner better than is accomplished in planes as now commonly constructed. Furthermore, the means described for holding the bit in place by means of the bow-spring are exceedingly simple in and economical of construction, besides being effective in the highest degree.

Having thus explained the nature of the invention and described away of constructing and using the same, though without attempting to set forth all of the forms in which it may be made or all of the modes of its use, it is declared that what is claimed is —

1. A block or smoothing plane comprising in its construction a planer-iron or bit and bit-support; a bow-spring constructed to bear at its ends upon the forward and rear ends of the bit; and a headed stud, the bow-spring having a centrally-arranged keyhole-slot to engage the head of the stud as set forth.

2. In a device of the class described the combination with a walled base-piece having a projection on its upper face, of a headed stud mounted in the projection, a slotted bit suitably arranged on the stud, shoulders arranged diagonally of the side walls of the base and forming supports for the bit, a thumb-screw having bearings in said projection of the base and the rear wall, a screw-threaded traveler upon the thumb-screw, having connection with the bit and a bow-spring engaging the head of the stud and bearing at its ends upon the ends of the bit to secure the latter in position and provided with a toat upon its upper face.

In testimony whereof I have signed my name to this specification, in the presence of two subscribing witnesses, this 4th day of September, A. D. 1897.

PATRICK SHEA.

Witnesses:

ARTHUR W. CROSSLEY,

W. SHEA.