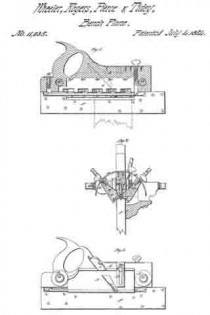

No. 17,553 – Stock For Bench Planes (Joel Bryant) (1857)

UNITED STATES PATENT OFFICE.

_________________

JOEL BRYANT, OF BROOKLYN, NEW YORK.

STOCK FOR BENCH-PLANES.

_________________

Specification of Letters Patent No. 17,553, dated June 16, 1857.

_________________

To all whom it may concern:

Be it known that I, JOEL BRYANT, of the city of Brooklyn, in the county of Kings and State of New York, have invented an Improvement in Bench or Carpenters’ Planes: and I hereby declare that the following is a full and correct description thereof, to wit:

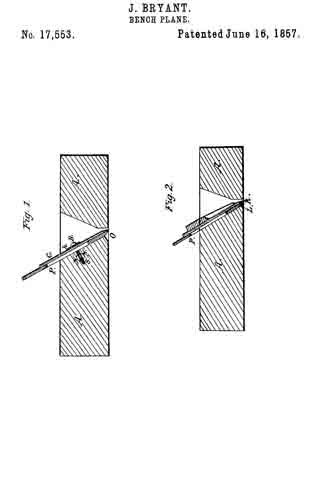

The nature of my invention consists in removing the recess, back of the plane iron — formed by the lower edge or tip of the plane stock, and the bevel edge of the plane iron — the said recess serving no purpose whatever, but, as is well known, a troublesome annoyance in catching splinters and small pieces of wood, obstructing the use of the plane. And, also, in addition to the removal of the recess, I have invented a new and more convenient method ot securing the plane iron and its cap together (where a cap is used), and, in the plane stock, by means of a single screw bolt and a sunken nut, the said screw and nut operating in connection with the plane iron and cap, as shown in the accompanying drawings Figure 1. and by the letters and figures marked thereon and forming a part of this specification.

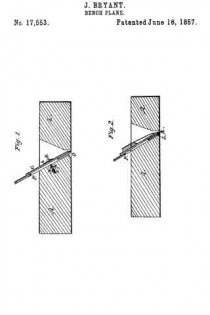

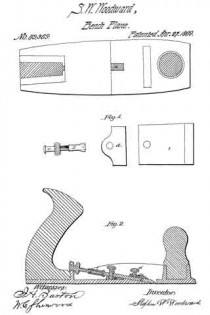

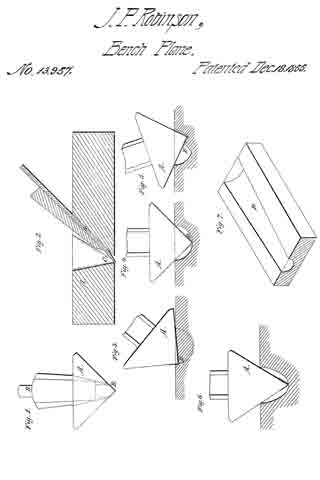

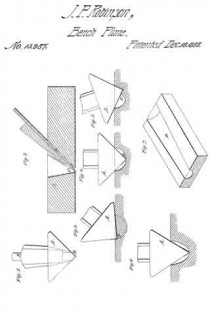

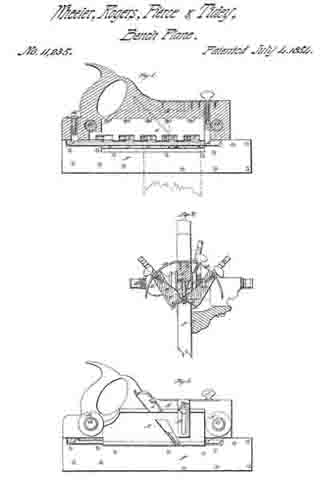

Fig. 1, in the accompanying drawings, is a longitudinal section of a bench plane, showing my improvement in the removal of the recess (R, Fig. 2,) as found in ordinary bench planes (Fig. 2). The recess (R, Fig. 2,) being removed by cutting off, or dispensing with the lower edge or tip (L, Fig. 2,) as far up in the stock (A,) as the upper part of the bevel of the plane iron goes to where the said plane iron (P) fits snugly to its bed in the plane stock (A) leaving in its room and stead an opening (O), having a backward inclination for the easy transit of any bits or small pieces that might pass the plane iron (P,) the said opening (O) being thus bounded on all sides by the snugly fitted plane iron (P) in the bed of the plane stock (A) it leaves no lissures or crevices in which splinters or bits of wood can fasten or stick; and thus, by this simple device, a most troublesome and vexatious annoyance is got rid of, without any inconvenience or disadvantage whatever, the said lower edge or tip (L) being of no use.

The other improvement in bench planes, is plainly shown in the said Fig. 1 by the screw bolt (B,) with its head (h) and shank (S,) in connection with the plane iron (P) and cap (C), and the sunken nut (N). The said shank (S,) being provided with a screw thread, passes through the said plane iron (P,) and cap (C) enters and fastens into the said sunken nut (N,) having a corresponding screw thread cut therein, the said screw bolt (B,) is screwed down into the said sunken nut (N,) and left with its head (h) resting upon, binding together, and firmly securing the said plane iron (P,) and cap (C,) in their place and bed in the plane stock (A), thus avoiding by this improvement the use of a wedge, or any other complicated contrivance for securing the plane iron and cap together and in the plane stock, thereby saving expense in the construction of plane stocks, and gaining an advantage and convenience in adjusting and securing plane irons over any other contrivance hitherto known or used.

I am aware that metal plane stocks have been invented with an iron tip for filling the said recess which I remove. I am also aware that an invention exists for securing the plane iron and its cap together and afterward, in the plane stock, by means of a “hook headed bolt, two nuts, and a cam shaft,” but these are essentially different from my invention; therefore, disclaiming all and every other alleged iinprovement in bench planes, (unless substantially the same as is herein set forth and described as my invention,) I institute my claim for what I desire to secure by Letters Patent as follows, to wit:

I claim the construction and use ot bench planes having an opening with a backward inclination made by the dispensing with, or the removal of the lower edge or tip of the plane stock ( as existing in bench planes of ordinary construction), the said opening being made for the purpose of avoiding the annoyance produced by splinters or small pieces of wood fastening into the recess, as formed by the said lower edge or lip of the plane stock and the bevel of the plane iron (in common bench planes) substantially as herein described and for the purpose set forth.

JOEL BRYANT.

Witnesses:

A. H. BIGELOW,

MELVILLE BRYANT.