No. 385,231 – Plane (Julius Armin Bissegger) (1888)

UNITED STATES PATENT OFFICE.

_________________

JULIUS ARMIN BISSEGGER, OF NEW YORK, N. Y.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 385,231, dated June 26, 1888.

Application filed November 8, 1887. Serial No. 254,632. (No model.)

_________________

To all whom it may concern:

Be it known that I, JULIUS ARMIN BISSEGGER, a citizen of the United States of America, and a resident of the city, county, and State of New York, have invented certain new and useful Improvements in Planes, of which the following is a specification.

The present invention relates to planes, and particularly to rabbet-planes, the object whereof being to insure accuracy in the operation thereof, and otherwise increased efficiency therein; and it consists in the construction and combination of parts, all substantially as will be hereinafter fully described, and pointed out in the claims.

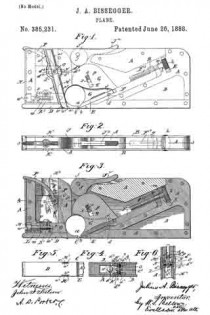

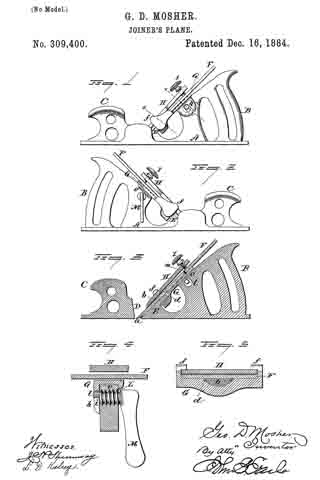

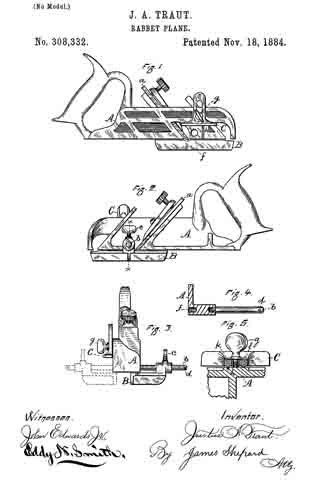

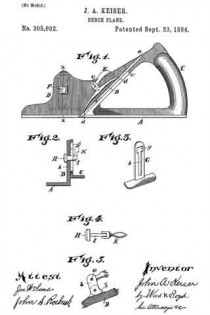

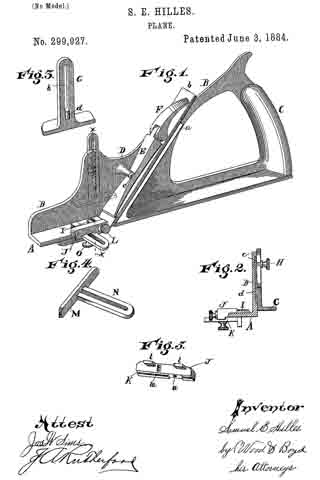

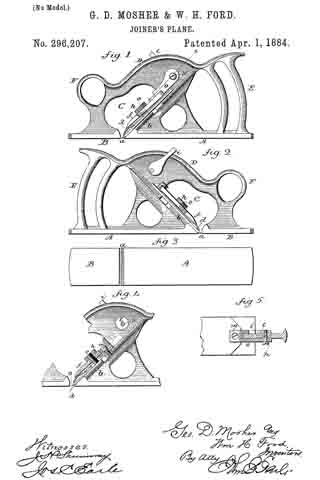

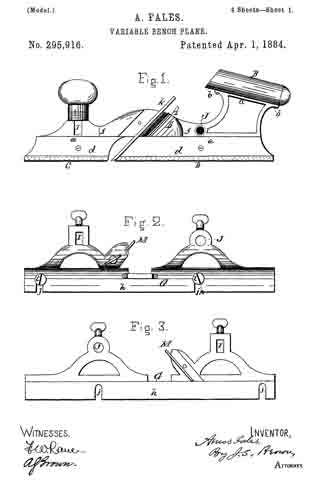

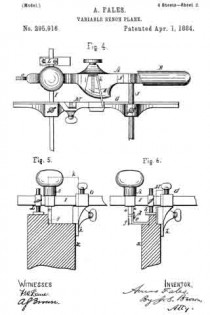

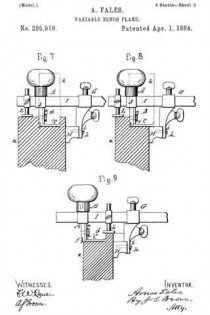

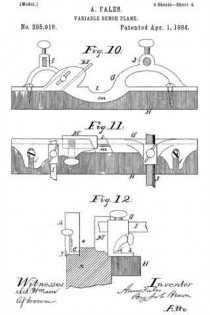

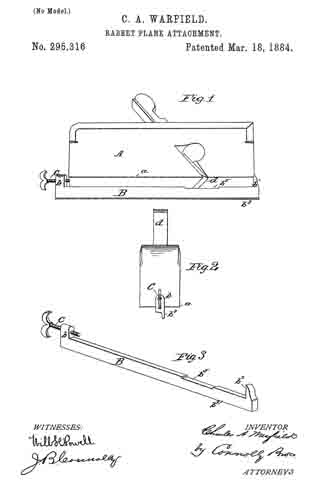

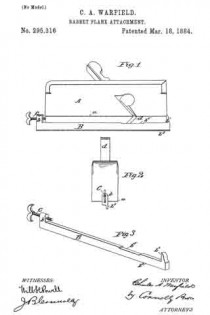

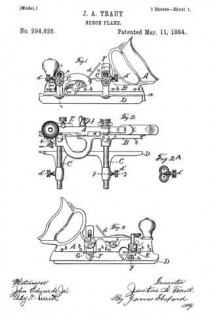

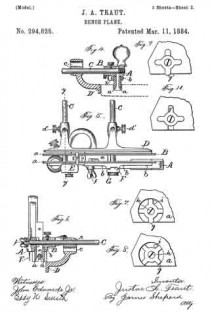

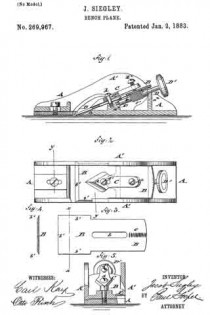

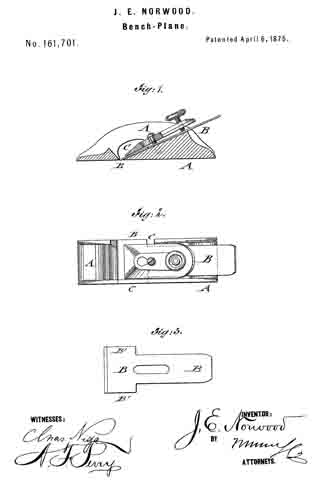

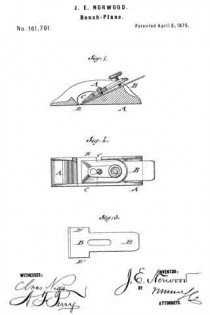

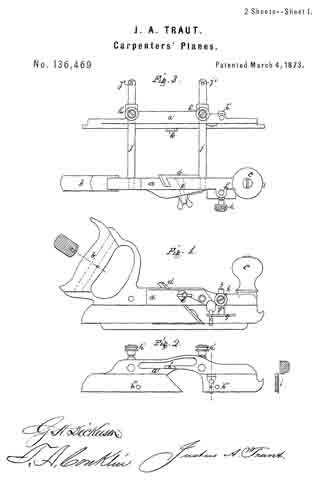

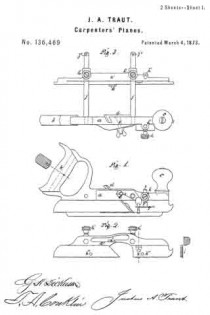

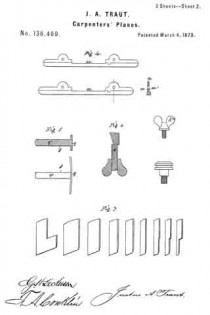

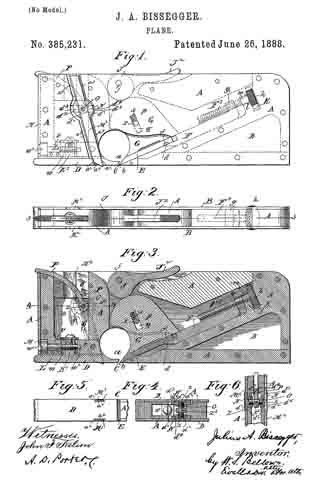

In the accompanying sheet of drawings, Figure 1 is a side view of a plane comprising the present invention. Fig. 2 is a plan view of same. Fig. 3 is a central vertical section of the plane on line 3 3 of Fig. 2. Fig. 4 is a horizontal sectional view in detail on line 4 4, Fig. 3. Fig. 5 is a plan view of a portion of the face of the plane. Fig. 6 is a section on line 6 6, Fig. 3.

In the drawings, A represents the plane body or stock, having plates B at each side thereof, covering the whole area thereof, except at the portion a, at and over the plane-throat C.

D is a throat-plate adapted to be movable, as hereinafter explained, and E is the plane-iron, having cutting-edge b, as usual in planes.

F is the plane-iron holder, which has a transverse rib, d, corresponding and closely fitting a transverse groove, f, in the plane-iron. The upper end of the plane-iron holder is provided with a right-angled lug or ear, g, through the inner screw-thread of which a screw-threaded bolt, F2, engages. This bolt F2 has a head, h, which lies in a recess, K, at the rear of a lug, Z, in the casting, and the shank of the screw-bolt F2 plays loosely through a hole, m, therefor in said lug l. The head of the bolt F2 is milled, and at each side projects through apertures K in the side plates, B, of the plane-stock,and may be conveniently turned by the hand to project or withdraw the edge of the plane-iron at the throat, as is plain.

G is a block which bears on the upper side of the plane-iron, and it has a tongue, p, projecting upwardly in the inner recess of the plane-stock, through which is a slot, q, having a direction perpendicular to the plane-iron E, through which slot is passed a stationary pin, r, extending from side to side of the plane-stock. Above the stationary pin r, and bearing on and between it and the upper wall of the slot q, is a spiral spring, s, which tends to force the block G upwardly away from the plane-iron. Resting over and upon the edge of block G is a cam-disk, J, pivotally hung in the plane-stock, as at j, having a handle-arm, J2, and all so arranged that when said arm is swung downwardly, as shown, it will of itself so remain until swung upwardly from the plane-iron E, allowing same, through the turning of the screw-bolt, to be altered in its projection, or to be removed, as desired.

The throat-plate D has its outer face of the same width as the face of the plane-stock, and it has a tongue or upward projection, K2, extending into the open space w, formed in the stock A. Extending through the part v of the stock is a screw-threaded bolt, L, which engages the female screw-threads of the upward extension K2 of the throat-plate D, and the end of the screw-bolt L is supported in a socket, w2, in the part x of the stock, as seen in Fig. 3, said bolt being prevented from longitudinal movement in one direction by the end of socket w2, and in the other direction by its abutment against the plate M, secured on the end of the plane-stock. The plate M, however, has a hole, w3, of diameter smaller than that of the bolt L, opposite such head, through which a screwdriver or wrench may be inserted to engage with the screw-slot. By turning the screw-bolt in one direction the throat-plate is moved toward the plane-iron to contract the opening or throat C, and when turned in the other direction the throat-opening is thus widened.

M2 M2 are pointed blades or groovers which are located at opposite sides of the plane in longitudinal lines coincident with the outer edges or corners of the plane-iron, as shown in plan view, Fig. 5, in advance of the plane iron. These blades are adapted and intended to be projected a distance beyond the face of the plane as great at least as the projection beyond the face of the plane of the plane-iron, and in the operation ofthe plane, in the usual manner, the blades M2 M2 form parallel grooves or demarkations, exactly within and between which the cutting plane-iron E follows and cuts the shaving.

The grooving-blades M’ M” extend through dovetailed grooves a2 in the throat-plate, and are beveled or dovetailed on their edges, fitting the dovetailed grooves in the throat-plate. There is also a clamp, N, for receiving each grooving-blade, having inner dovetailed grooves, d2, corresponding to the dovetail shape of the blades M2. The clamps N2 are adapted to be drawn inwardly, carrying the blades M2 therewith in a transverse line of the plane and firmly against the stock at its portion a3 above and below the clamp N, and inwardly against the inner wall, a4, of the grooves in the throat~plate, and this inward bind of the grooving-blades is secured by the screw-pin O, differentially threaded at its opposite end portions z, having intermediate of its length a squared portion, z2, by which a permanent or other wrench-arm, P, engages, the turning of which screw-pin in one direction causes the clamps N to move inwardly, and the turning of the screw-pin in the opposite direction causing the clamps to move outwardly for maintaining the bind of the blades M2 against the side of the stock and throat-plate, or for releasing such bind to permit the adjustment or release of the grooving-blades.

The opposed sides of the stock A. are provided with horizontal ways or grooves d3, in which play projections d4 of the clamp N, permitting the clamps to move longitudinally of the plane-stock, as the blades are so carried when the throaaplate D is moved longitudinally either to widen or contract the throat.

Having thus described my invention, what I claim, and desire to secure by Letters Patent, is —

1. The combination, with the plane-stock having the pin r, the cam J, and the plane-iron, of the block G between said cam and plane-iron, having slot q, substantially as described.

2. The combination, with the plane-stock having the pin r, the cam J, and the plane-iron, of the block G between said cam and plane-iron, having slot q, and spring s, substantially as and for the purpose described.

3. The combination, with the recessed plane-stock having lug m, screw F2, ribbed plane-holder F, having lug g, notched plane-iron E, and pivoted cam J, having handle J2, of block G between said cam and plane-iron, having slot q, and spring s, substantially as and for the purpose described.

4. The combination, with a plane-stock having vertically-arranged recesses a3 a3, and the horizontal grooves d3 d3, of the clamping-blocks N N, having dovetailed sockets, inwardly-extending projections d4, and threaded screw-receiving holes, the right and left threaded screw having the intermediate projecting lever, P, and grooving-knives having dovetailed edges bearing in said socketed block, substantially as described, for the purposes set forth.

In testimony that I claim the foregoing as my invention I have signed my name in presence of two witnesses.

JULIUS ARMIN BISSEGGER.

Witnesses:

WM. SEARS BELLOWS,

CHAS. S. SENTELL.