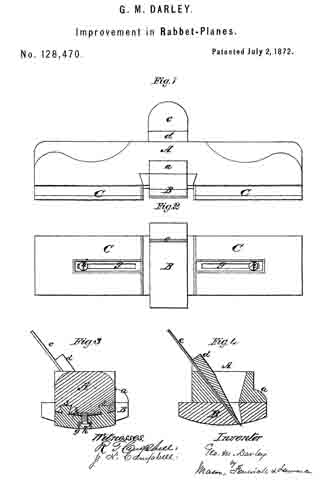

No. 128,470 – Improvement In Rabbet-Planes (George M. Darley) (1872)

UNITED STATES PATENT OFFICE.

_________________

GEORGE M. DARLEY, OF NEBRASKA CITY, NEBRASKA.

IMPROVEMENT IN RABBET-PLANES.

_________________

Specification forming part of Letters Patent No. 128,470, dated July 2, 1872.

_________________

To all whom it may concern:

Be it known that I, GEORGE M. DARLEY, of Nebraska City, county of Otoe and State of Nebraska, have invented a new and Improved Rabbet-Plane; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawing making part of this specification, in which —

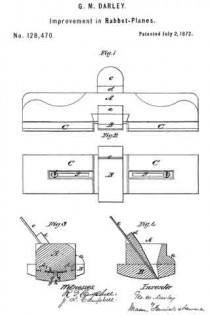

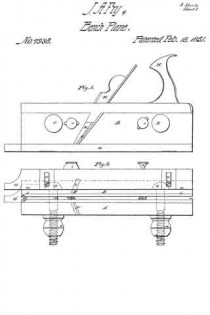

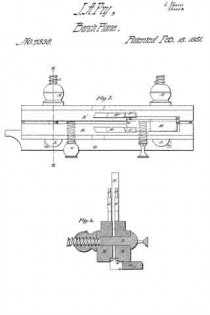

Figure 1 is a front view of the plane. Fig. 2 is a bottom view of the plane. Fig. 3 is a section through dotted line x x. Fig. 4 is a section through dotted line y y.

Similar letters of reference indicate corresponding parts in the several figures.

This invention relates to an improved plane, which is designed for rabbeting circular as well as oval work. It consists in the combination of adjustable gauges with a plane, as will be hereinafter explained.

The following description of my invention will enable others skilled in the art to understand it.

In the accompanying drawing, A represents the stock of the plane, which may be made of any desired length, and which is curved on top at its ends so that it can be conveniently grasped in the hands. This stock A is centrally throated to receive the plane-iron c and wedge d, and beneath this throat the sole or face B of this plane is secured in a suitable manner. This sole presents a convex surface, which is below the corresponding surface of the stock. It is convex transversely, and its ends extend out from the front and back sides of the stock A, as shown in Figs. 2, 3, and 4.

The front projecting end of the sole B is sustained against undue strain by a shoulder, a, which is formed on the stock A. On each side of the sole B is a gauge, C, the wearing face of which is protected by metal. Each gauge C is adjustable endwise, and is applied to the stock A by means of dovetail tenons s s, shown in Fig. 3. Each gauge is slotted longitudinally, as shown at g, which slot receives through it a set-screw, h, which is tapped through a plate, p, on the bottom of the stock, and serves to fix the gauge at any desired point. Instead of a set-screw, h, a bolt may be used for each gauge G, which will pass vertically through the stock A and receive on its upper end a nut.

It will be seen from the above description that I have a right and left hand rabbeting-plane, which can be adjusted for any desired width of rabbet by means of the gauges C, and which is adapted for all kinds of circular or oval work.

Having described my invention, what I claim as new, is —

The centrally-throated stock A, with its depressed sole B, in combination with the adjustable gauges C C, substantially as described.

GEORGE M. DARLEY.

Witnesses:

Z. N. CAMPBELL,

EDM. F. BROWN.