No. 10,748 – Bit Fastening For Cast Iron Bench Planes (William S. Loughborough) (1854)

UNITED STATES PATENT OFFICE.

_________________

WM. S. LOUGHBOROUGH, OF VICTOR, NEW YORK

BIT-FASTENING FOR CAST-IRON BENCH-PLANES.

_________________

Specification of Letters Patent No. 10,748, dated April 4, 1854.

_________________

To all whom it may concern:

Be it known that I, WM. S. LOUGHBOROUGH, of Victor, in the county of Ontario and State of New York, have invented a new and useful Improvement in Cast-Iron Bench-Planes; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings and to the letters of reference marked thereon.

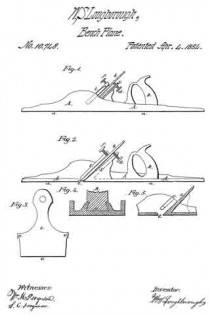

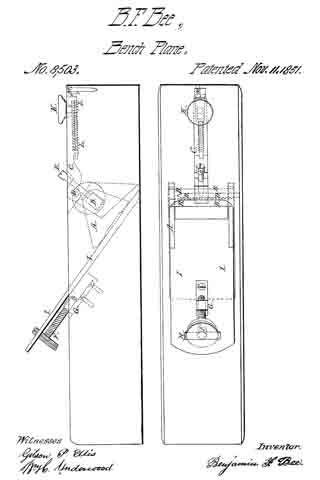

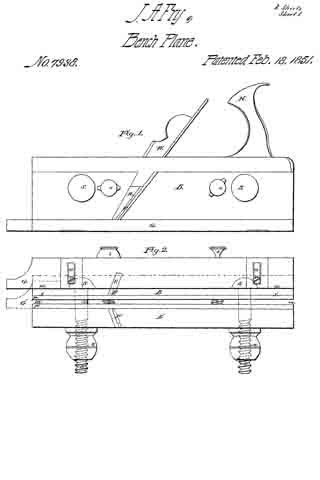

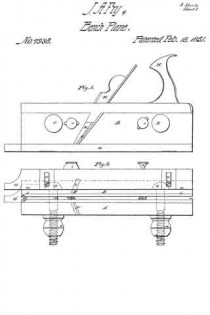

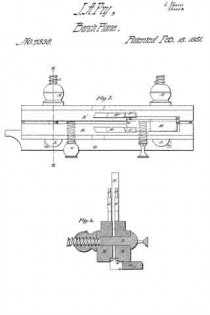

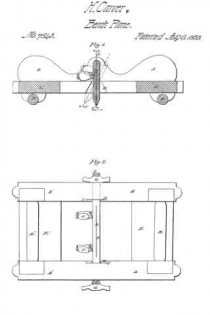

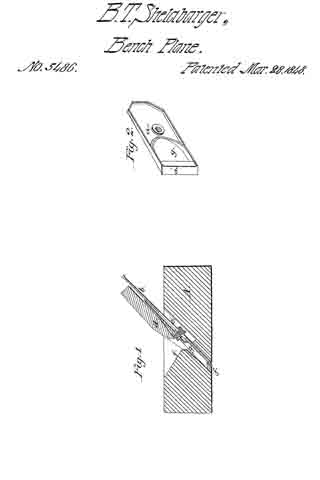

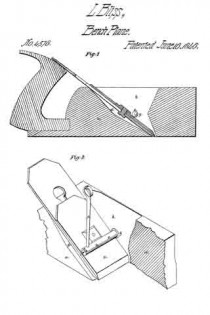

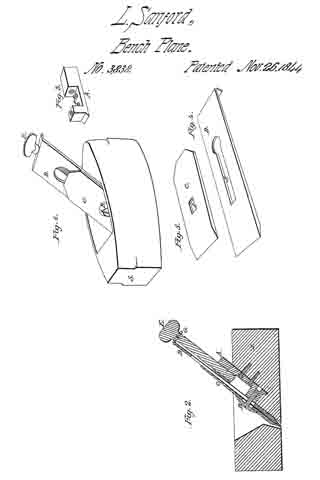

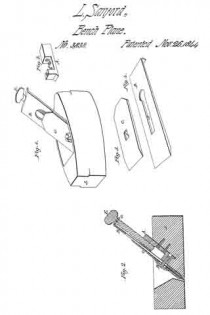

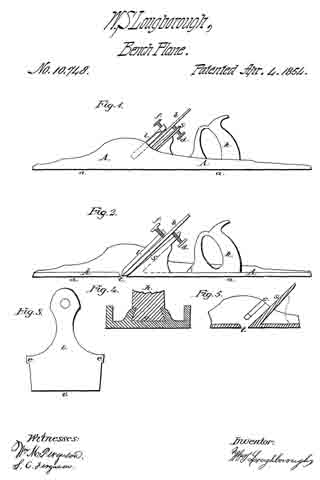

Figure 1, is a side perspective. Fig. 2, is a perpendicular horizontal section, in which is represented the combination of the various parts. Fig. 3, is a plan of the adjustable, lever-cap l, showing the points e that form its fulcrum. Fig. 4, is a transverse section of the plane, through the handle h, showing the dovetail groove g, for the handle. Fig. 5, is a section of a part of one side, from within, showing the groove c, in which the fulcrum e, of the adjustable lever-cap l operates.

The nature of my invention, consists in the simplicity, convenience and perfection of its construction and operation. I prefer that form, for the body or stock of the plane, represented in the drawings, marked A–A, as it affords suficient strength in a very light article, when such is required.

s, seen in Figs. 1, 2, and 5, is the stem through which the screw d, — (seen in Figs. 1-2,) — works, and as it forms a part of the body, or stock of the plane, — being cast with it, it requires no fitting or adjusting thereto, as is the fact with that part of M. Chardoillet’s planes, and the lever, cap, and bit in his, being connected with this stem, directly, and the whole made to swing on a pivot that unites them with the stock, — the combination is much more complicated in that respect, than mine, besides, I avoid the necessity of a cap as a distinct and separate part, by using the lower end of the adjustable lever-cap, l, as a cap, when a double iron is required, thereby producing two desirable results, with one device.

Said device, (lever-cap l,) is operated, or adjusted by the screw f, operating upon the upper end of the bit, b, — its lower end, (marked v, in Fig. 3,) resting on the bit near its edge, and the fuicrum, e e, (in Fig. 3,) connecting with the stock in the grooves c c, one of which is shown in Fig. 5. This also fastens the bit. These grooves, (c c,) may be molded in the pattern, or may be cut by a ciicular file attached to the mandrel of a lathe.

To regulate the plane to plane veneers, and cross-grained lumber, &c., it is necessary to close the throat, 25, (in Figs. 2 and 5,) so as to prevent a thick shaving from raising, which would be the result, with the throat open, though you might have the cap of the double iron perfectly adjusted. The lever-cap l, may be raised at such times, — (as it is not needed as a cap,) and thus permit the shaving, however thin and weak to pass tlgrough entirely unobstructed, and without clogging.

All that is necessary to be done, to remove the bit b, is to give the screw f, a slight turn to the left, and the bit is loosened, and vice versa.

There are various ways of attaching the handle, h, to the stock. That represented in Fig. 4, is probably the best, being simply to mold in the pattern a dove-tail groove, g, to which the handle may be fitted and driven in.

What I claim as my invention and improvement, and desire to secure by Letters Patent is —

1. The combination of the adjustable lever-cap, l, with the screw, f, by which it is operated.

2. The manner of connecting the said adjustable lever-cap l, with the stock of the plane, as described, and for the purposes set forth.

WM. S. LOUGHBOROUGH.

Witnesses:

WM. M. FERGUSON,

S. C. FERGUSON.