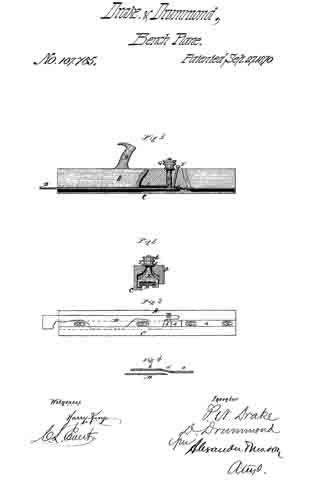

No. 107,765 – Improvement In Splint-Planes (Philander N. Drake And David Drummond) (1870)

United States Patent Office.

PHILANDER N. DRAKE AND DAVID DRUMMOND, OF MCGREGOR, IOWA.

Letters Patent No. 107,765, dated September 27, 1870.

_________________

IMPROVEMENT IN SPLINT-PLANES.

_________________

The Schedule referred to in these Letters Patent and making part of the same.

_________________

To all whom it may concern:

Be it known that we, PHILANDER N. DRAKE and DAVID DRUMMOND, of McGregor, in the county of Clayton and in the State of Iowa, have invented certain new and useful Improvements in Splint-Plane or Slat-Cutter; and do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawing and to the letters of reference marked thereon, making a part of this specification.

Our invention relates to that kind of planes used in cutting thin strips or slats for rustic shades, and other purposes, and consists —

First, in placing the cutter under the bottom of the plane, level with the edge of the board from which the strips or slats are to be cut;

Second, in the construction of the mechanism for holding the cutter in its place; and

Third, in the construction of the mechanism for regulating the thickness of the strips or slats to be cut.

In order to enable others skilled in the art to which our invention appertains to make and use the same, we will now proceed to describe its construction and operation, referring to the annexed drawing, in which —

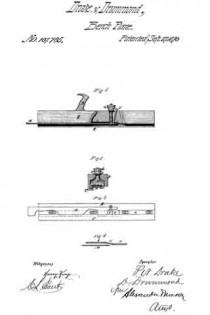

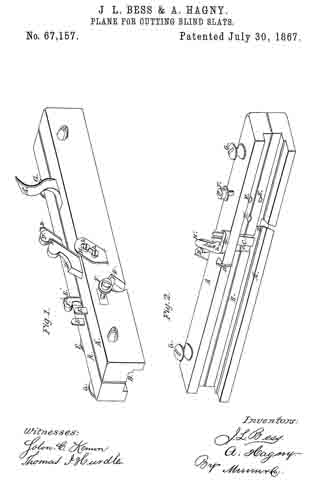

Figure 1 is a side view, part in section, of our plane;

Figure 2 is a transverse vertical section; and

Figure 3, a bottom view of the same.

Figure 4 shows the end of the cutter, with the channel-plates in the plane.

A represents the body of our plane provided with a handle, B.

Along one side of the body A is secured a bar, C, projecting below the plane a suitable distance to form a guard or guide for the tool.

Between the under side of the plane A and the bar C is formed a groove, in which the inner edge of the cutter D is inserted, said cutter being laid level under the lower side, or against the lower side of the plane A.

The cutting-tool D is held by means of a stirrup, E, constructed as shown in fig. 2, and passed up through the plane A, with a screw-shank at its upper end, which projects above the plane.

On this screw-shank is placed a thumb-nut, G, by means of which the stirrup is raised so as to firmly bind the cutting-tool. The pitch of the cutting-edge of said tool is regulated by means of two inclined screws, I I, passing through the plane A and bearing against the upper surface of the cutter, one on each side in front of the stirrup E.

The tool-bit being on a level with the edge of the board, it splits with less liability to break the fiber on the back of the slat. When it is to be taken out to sharpen, it can be put back to its place accurately and cut all the work of uniform thickness.

The two screws, I I, forcing the cutting-edge of the cutter to the desired position for uniform thickness, may, of course, remain in the same position for any length of time without change, even though the cutter is taken out and replaced again.

In the channel on the under side of the plane A, between it and the cutter D, are placed three channel-plates, a, b, and d, the relative positions of which are plainly indicated in fig. 4. The object of these plates is to further enable us to vary the thickness, if we desire to do so.

The back or upper side ofthese plates may be provided with inclines to enable them to be pushed forward or back.

The middle plate d is made so that it can readily be taken out and another of different size substituted.

Having thus fully described our invention,

What we claim as new, and desire to secure by Letters Patent, is —

The combination, with the stock A, of the flat-laid tool D, channel-plates a b d, stirrnp E, nut G, and screws I I, all constructed to operate substantially as set forth.

In testimony that we claim the foregoing, we have hereunto set our hand and seals this 26th day of March 1870.

PHILANDER N. DRAKE. [L. S.] DAVID DRUMMOND. [L. S.]

Witnesses:

A. J. JORDAN,

ORLANDO McCRAREY.