No. 120,212 – Improvement In Carpenters’ Planes (Russell Phillips) (1871)

UNITED STATES PATENT OFFICE.

_________________

RUSSELL PHILLIPS, OF BOSTON, MASSACHUSETTS.

IMPROVEMENT IN CARPENTERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 120,212, dated October 24, 1871.

_________________

To all whom it may concern:

Be it known that I, RUSSELL PHILLIPS, of Boston, in the county of Suffolk and Commonwealth of Massachusetts, have made an invention of certain Improvements in Carpenters’ Planes; and do hereby declare the following to be a full, clear, and exact description thereof, due reference being had to the accompanying drawing making part of this specification, and in which —

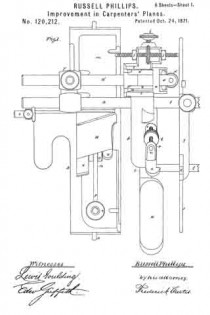

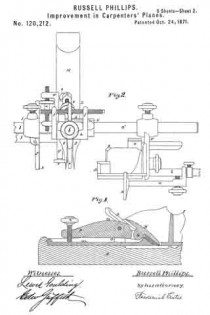

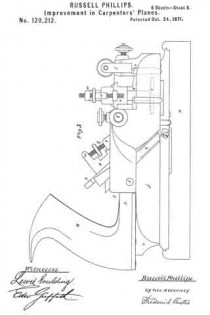

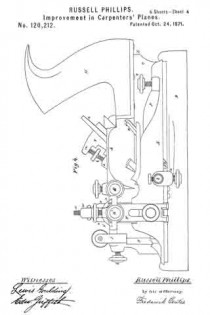

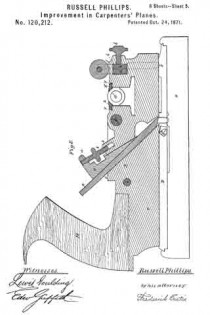

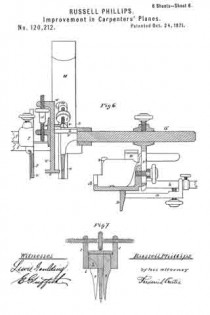

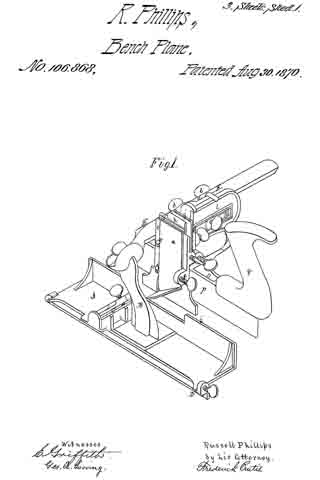

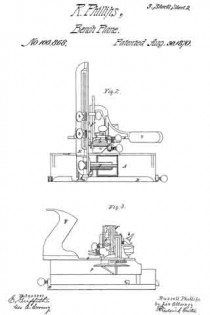

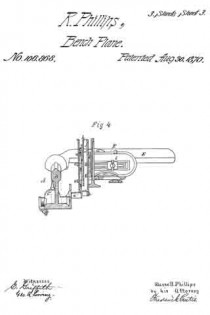

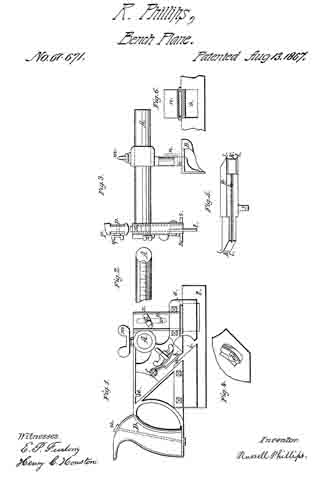

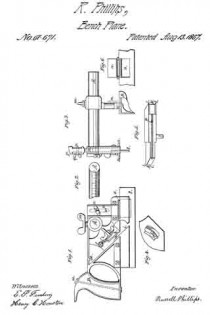

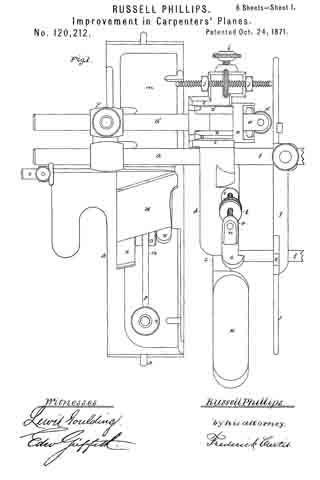

Figure 1 is a plan; Fig. 2, a front elevation; Figs. 3 and 4, opposite side views; and Figs. 5 and 6, vertical sections of a combination plane embodying my improvements. Fig. 7 is a transverse section of the adjustable scoring-spurs, to be hereinafter explained; and Fig. 8, a vertical section of the key of the outermost plow-plane and the device for adjusting the same; Fig. 9, a longitudinal section of the device tor clamping the cutter of the rabbeting-plane, which will be duly explained in the context.

This invention may be considered an improvement upon that for which Letters Patent of the United States have already been issued to me. I have in this instance, as in the former, called the instrument a combination plane, since it embodies three planes of different natures, either of which may be used alone to perform its ordinary functions, if desired, while in the general combination provision is made whereby the three or two of the three planes maybe adapted to execute work unattainable by one, while still further either plane may be removed from connection with its neighbor and used as an independent tool to perform its own individual duty.

The primary elements of this combination consist, first, of a central cross-grooving and plow-plane, such central portion carrying the handle of the combination implement and supporting upon either side, in an adjustable manner, the two other primary elements of the combination, which are a rabbeting-plane and a second cross-grooving and plow-plane, the implement as a whole being susceptible of cutting the tongue and groove in matching stuff, of cutting narrow or extremely wide cross-channels or longitudinal grooves, of performing all the functions of a rabbeting-plane, and finally, of reducing wood to a certain form. in executing moldings by hand, by which much of the labor of roughing out the molding is avoided.

In the drawing accompanying and illustrating this description of my invention, A denotes a metallic rabbeting-plane, substantially of ordinary production with the exception of the absence of a handle and the employinent of a. thumb-guard or hand-rest, B, erected upon its side, the said rabbeting-plane being further distinguished from others of its class by the addition to its under side of an adjustable gauge, D, which converts it into a style of plane known as a “filister”-plane, or those in which the width of the rabbet cut by the tool is governed at pleasure, this gauge being pendent from and controlled by a horizontal arm, a, extending laterally below the plane-bed or plate, which arm in turn is mounted and slides freely upon a rod or bar, b, affixed to and departing laterally from the outer edge of the said plane-bed, and is provided with a set-screw, whereby the two may be clamped together when the desired position of the gauge is insured. Each end ofthe gauge D overlaps the upper edge of that of the plane-bed in order to insure a steady position and relieve the arm a and rod b of the thrusts and strain to which they would be otherwise subjected. A movement of the gauge D to and fro of the plane A with respect to the inner side or the latter determines the width of the cut effected by the iron E of such plane. The plane A is suspended at its outer forward part from a furcated or slotted hanger, F, which is mounted upon and depends from two horizontal parallel rods, G G’, the hanger sliding freely upon such rods, and a set-screw being combined both with the hanger and rods and the plane A, by which both the height and lateral position of such plane with respect to the central plow-plane are varied and determined. This last-named plow-plane, shown at L in the drawing, is the central member of the combination, and bears at rear end the handle H of the combination instrument, such plow-plane being virtually of ordinary construction and composed of an upright blade or sword, c, and a narrow shelf, d, at top, the iron or cutter of this plane being shown at e, while the two horizontal rods or supports G G’ before named depart laterally from this shelf at or near the forward end of the plane, as represented. The second and outermost cross-grooving plane is shown at I in the drawing as simply an upright thin blade or fence, J, carrying in the ordinary manner a cutter, K, this plane I being mounted upon and sliding to and fro of two horizontal lateral guides or rods, f f which extend from the outer side of the central plane I, the said plane being provided with a set-screw, whereby its position upon its guide-bar and its relation to the central plane L are determined. The said plane I serves as a valuable adjunct to the central plane L, inasmuch as the two together are susceptible of cutting a very wide cross-groove, while also, and detached from the other, such plane I is an entirety in itself and is an ordinary cross-groove plane. The scoring-spurs of the central plane L are shown at g g, as disposed at the forward end of such plane and affixed each to a vertical flat plate, h, the two plates overlapping each other and being situated within an orifice, i, created in the sword c and below the shelf d and at right angles to the longest plane of such sword, and remaining upon opposite sides of said sword, and consequently of the cutting-iron carried by it. Each plate h is prolonged into a vertical post, j, while disposed between these posts, and screwing through each, is a right-and-left-threaded screw, by turning which in one or the other direction the spurs are caused to approach to or recede from one another, and thus adapt them to a cutter of any width. In order to adapt the two spurs bodily together to the position of the cutter — that is, to bring the whole into alignment with the general plane of the sword c –I employ a set-screw, l, which enters the orifice i before named and serves to clamp the two spurs firmly into place together at any desired point transversely of the sword and with respect to the cutting-iron e. The cutter-iron E of the rabbeting-plane A is clamped in position upon its bed in by a cap-plate, M, to the under side of which one end of a lever, n, is pivoted, the fulcrum of this lever being a short post, o, erected upon the base of the plane and immediately in rear of the iron E, while screwing downward through the outer and longer arm p of this lever, and abutting again st the said base, is a screw, q, as shown in the drawing. Turning the screw in one direction elevates the longer arm p of the lever and forces the cap-plate M upon the plane-iron E with a powerful pressure, and confines the latter securely in place upon its bed. Reversing the motion of the screw relaxes the pressure upon the parts and permits the adjustment or removal of the cutter. The key of the central plow-plane, which confines its cutter in place, is shown at c in the drawing as a tapering or wedge-shaped block disposed between the cutter and the abutment S, making part of the shelf d hereinbefore mentioned, and the vertical movements of this key in tightening or loosening the cutter are effected by a right-and-left screw, t, which screws at one end into the abutment s and at the other through an arm, u, which constitutes the upper termination of the said key. A turn of the screw in one direction elevates and in the opposite direction lowers the key r, and the action of such key upon the cutter will be at once understood. The depth-gauge of the central plane L is shown at u as a flat horizontal plate, v, :making part of an upright bar, w, which in turn is suspended in an adjustable manner irom a carriage, x, this carriage being supported and sliding within horizontal ways or guides y y formed in the upper forward part of the sword of the plane or the shelf d, making part thereof. The carriage x and the bar u’ of the depth-gauge have each an outstanding lateral shelf, z or z’, the two being disposed opposite each other, while passing through these two shelves is a right-and-left-threaded screw, a’, by means of which the depth of the gauge with respect to the sword and cutter of the plane may be adjusted. It will be observed that the depth-gauge u may be, if desired, fixed immovably to either side thereof.

In the above combination of parts, by lowering the rabbeting-plane A it may be made to serve as a guide or stop to the central or outer plow-planes, or both combined, when used in matching stuff or other purposes, while, as before observed, such plane disposed below the base of the central plane and operating with its adjustable gauge D enables two rabbets to be cut at one and the same time, which will be found of great service in cutting uncommon or irregular moldings by hand, and in exceptional cases in tonguing and grooving. The simple and efficient mode of applying the gauge D to the rabbeting-plane enables its adjustment to be effected instantly, and secures it very firmly to the base of the plane, while it may be made to perform the office of a gauge or guide to either the rabbeting-plane carrying it or to the central plow-plane. The adjustable method of combining the rabbeting-plane and the outer prong-plane with the central plow-plane, as herein shown, enables the combination implement to be set immediately to the proper gauge for cutting the tongue and groove in matching stuff.

I claim —

1. The combination, with the central plane L, of the rabbeting-plane A attached to said central plane in the manner and by means herein shown and described, in order to adjust it both vertically and horizontally in relation thereto.

2. The combination of the three planes A, I, and L in the manner shown and described, so that either or both of the latter two planes may be removed from the former for the purposes stated.

3. The combination, with the plane A, of the adjustable gauge D and the rod or support b under the arrangement shown and set forth.

4. The combination, with the plane L, of the spurs applied thereto in the manner shown and described, to allow them to be adjusted separately or jointly with respect to the cutter of the plane.

5. The combination, with the plane A and its cutter-iron, of the lever n, pivoted to the cap-plate m, inlcrumed to the post o, and provided with the elevating device q, substantially as herein shown and set forth.

6. The combination, with the clamping-key, of the plow-plane I and its abutment of the right-and-left-threaded screw t, in the manner and for the purposes shown and set forth.

RUSSELL PHILLIPS.

Witnesses:

FREDERICK CURTIS,

WILLIAM KEEFE.