No. 143,737 – Improvement In Splint-Planes (Henry L. Weagant) (1873)

UNITED STATES PATENT OFFICE.

_________________

HENRY L. WEAGANT, OF MORRISBURG, CANADA, ASSIGNOR OF TWO-THIRDS OF HIS RIGHT TO STEPHEN B. FELL AND ROBERT LYLE, OF SAME PLACE.

IMPROVEMENT IN SPLINT-PLANES.

_________________

Specification forming part of Letters Patent No. 143,737, dated October 14, 1873; application filed August 29, 1873.

_________________

To all whom it may concern:

Be it known that I, HENRY LUDWICK WEAGANT, of Morrisburg, in the county of Dundas and Province of Ontario, Canada, have invented new and useful Improvements in Splint-Planes; and I do hereby declare that the following is a full, clear, and exact description of the same.

By my invention a plane or slat-cutter is provided which will produce at each cut a slat, perfectly formed, beveled, properly straightened out, and then receiving the proper bend to facilitate its being woven, reference being had to the annexed drawings, where similar letters of reference indicate like parts, and where —

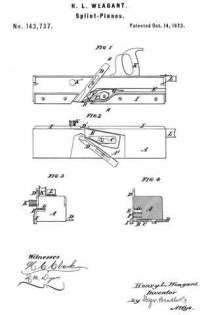

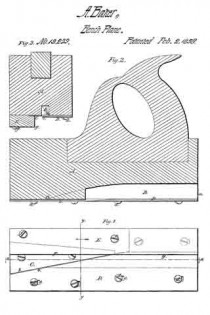

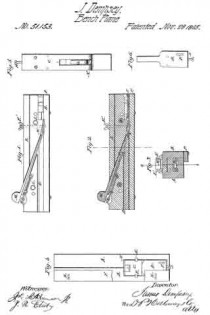

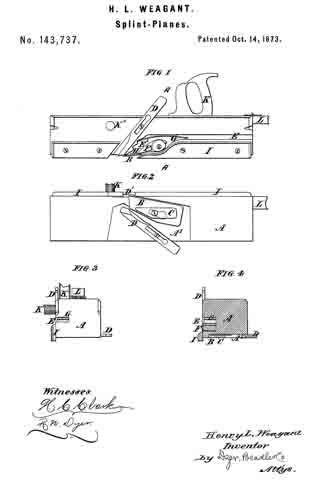

Figure 1 represents a side view, Fig. 2 a bottom view, and Fig. 3 an end view, of my slat-cutter. Fig. 4. represents a section of my slat-cutter on line A A.

A is the body of the plane or slat-cutter, in which is formed, as shown in Figs. 1, 2, and 4, a recess, A’. In this recess is placed the plane-iron B for cutting the slats, slotted in the ordinary manner, and further secured by a cap or stiffening piece, C. D D’ are the beveling-knives, slotted and secured, one to the side and the other to the bottom of the plane, and arranged so as to cut the beveled edges of the slats. E is a groove formed in the side of the plane, through which the slat just cut passes. F is what is termed the “governor,” placed in the throat E’ of the groove E, and secured preferably by means of a plate or washer and screw, its purpose being to straighten the slats as they pass irom the plane-iron B, the spring G materially assisting in doing this. H is a recess formed in the throat, and serving to give the slat when straightened the proper bend to enable it to be woven. I I are guides to keep the plane in its proper course, and K K’ handles for working the plane or cutter, L being another handle, which may be hinged to the stock, if required.

The operation of my invention is so simple as hardly to require any explanation, it being worked in the same way as an ordinary plane, and being applied to the edge of a board, the thickness of which is the required width of the slat.

The slat, being divided from the board by the iron B, has at the same time its edges beveled by the cutters or knives D D’. It then passes up over the governor F, and between it and the spring G, being thereby straightened, and, the end being caught in the recess H, is thereby slightly bent again, as required.

What I claim is as follows:

The combination of the plane-iron B and beveling-knives D D’ with the governor F, spring G, and recess H, as and for the purposes set forth.

HENRY L. WEAGANT.

Witnesses:

ROBERT LYLE,

ROBERT S. WEAGANT.