No. 98,108 – Improvement In Carpenters Plow (Royal B. Rice) (1869)

United States Patent Office.

ROYAL B. RICE, OF WILLIAMSBURG, MASSACHUSETTS.

Letters Patent No. 98,108, dated December 21, 1869.

_________________

IMPROVEMENT IN CARPENTERS’ PLOW.

_________________

The Schedule referred to in these Letters Patent and making part of the same.

_________________

To all whom it may concern:

Be it known that I, ROYAL B. RICE, of Williamsburg, in the county of Hampshire, und State of Massachusetts, have made and invented n new and useful Improvement in Carpenters’ Matching-Planes; and I do hereby declare that the following is a full, clear, und exact description of the construction and operation of the same, reference being had to the annexed druwings, making a part of this specification, in which —

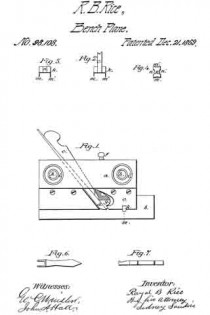

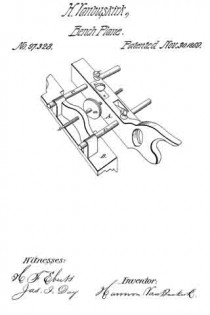

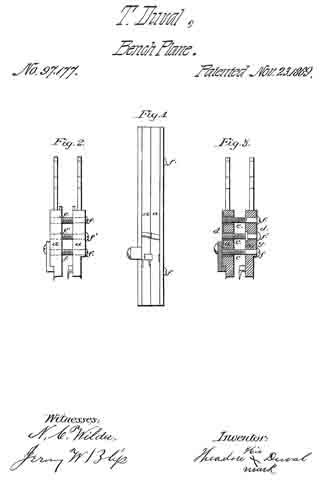

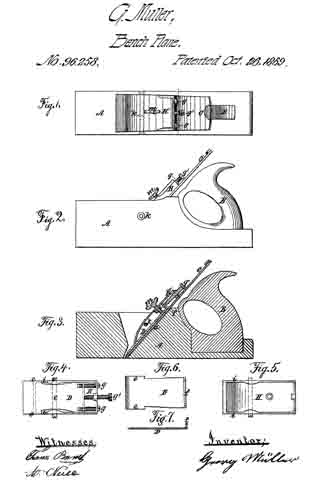

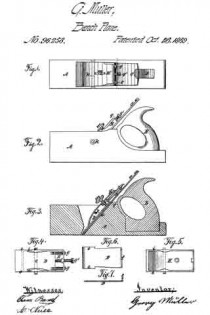

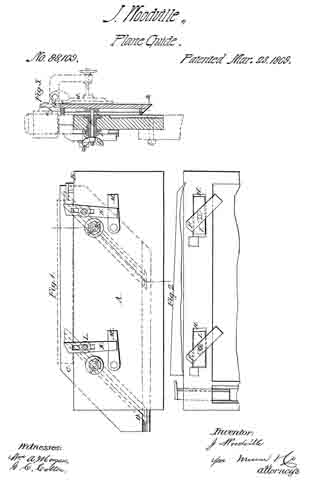

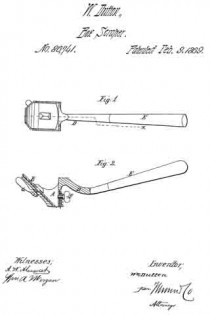

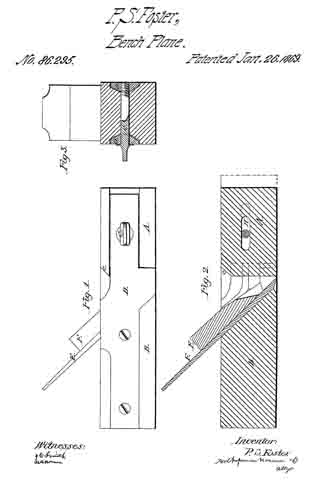

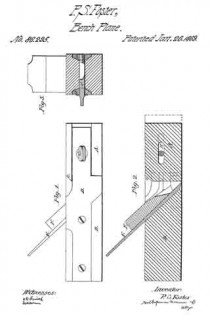

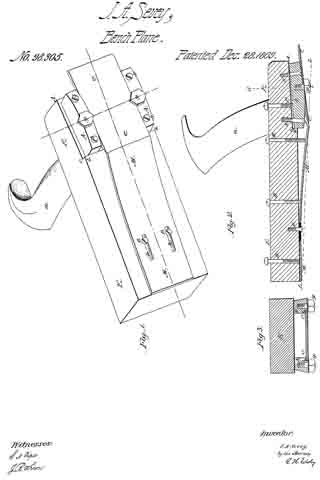

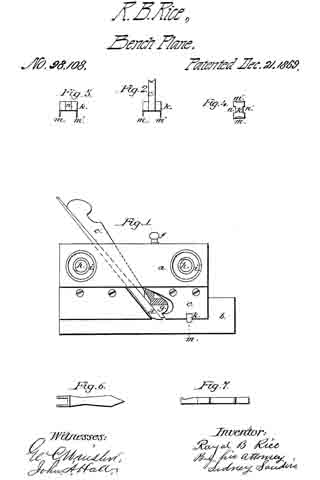

Figure 1 is a side elevation of a plane embodying my improvement.

Figure 2, a detached end elevation of the plate in which is arranged the coulter.

Figure 3, at side elevation of the coulter detached from the plate,

Figure 4, at plan of the coulter inverted.

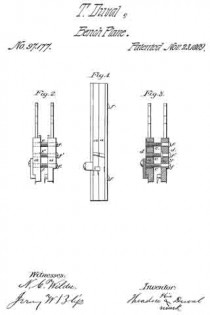

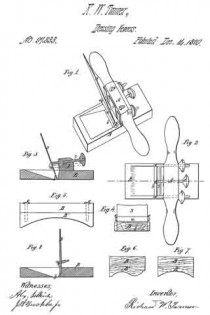

Figures 6 and 7, side and edge elevations of at tool for removing the coulter irom the plate.

In the accompanying drawings —

The part marked a represents the wood or body.

b, the fence.

c, the plate.

d, the bit.

e, the key.

f, the screw-knob, by turning which the foot g is raised or depressed, and the depth of the furrow thereby regulated.

h h’ are screws, provided with nuts i i’, also with corresponding nuts on the opposite side of the wood a, whereby is regulated the distance of the fence b from the plate c.

My invention consists in so constructing and arranging at coulter, with reference to the bit or iron d, that in “touguing” or “grooving” lumber, the edges of the shavings to be removed by the bit d shall have been previously cut by the coulter k, greatly facilitating such operations.

In practice, I make the coulter k of a rectangular form, providing the same with depending cutting-lips m m’, end with rebates n n’‘. In the plate c, I cut a notch, wherein I arrange the coulter, as in figs. 1 and 2. The coulter k is held in piece simply by fitting the notch in plate c snugly.

The lips m m, being lower than the bit d, first out the edges of the shavings, which are then removed by said bit.

The essence of my invention is the combination of the lips m m’ with the bit d.

By means of the tool represented in figs. 6 and 7 , the coulter k may be easily removed ffom plate c, and other coulters inserted to correspond with bits (d) of different widths that may be used in the same wood a.

Thus having described the construction and operation of my invention,

What I claim as new, and desire to secure by Letters Patent, is —

The coulter k, constructed and arranged with reference to bit d, as herein specified.

ROYAL B. RICE.

Witnesses:

T. M. CARTER,

J. B. GLEASON.