No. 721,771 – Plane (Jefferson Allen) (1903)

UNITED STATES PATENT OFFICE.

_________________

JEFFERSON ALLEN, OF KENNEBUNK PORT, MAINE.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 721,771, dated March 3, 1903.

Application filed April 11, 1902. Serial No. 102,366. (No model.)

_________________

To all whom it may concern:

Be it known that I, JEFFERSON ALLEN, a citizen of the United States, residing at Kennebunk Port, in the county of York and State of Maine, have invented an Improvement in Planes, of which the following description, in connection with the accompanying drawings, is a specification, like figures on the drawings representing like parts.

This invention has for its object the production of a novel plane in which the cutting edge of the plane-iron is situated some distance below the sole of the stock, whereby the plane may operate upon portions of the surface to be planed which are below the level of the higher portions thereof.

My improved plane is especially useful in such operations as smoothing up the boards of a floor.

In laying a floor it frequently happens that the surfaces of adjacent boards at their meeting edges are not in exactly the same horizontal plane, one board projecting slightly above the other to form a shoulder, and it also sometimes happens that owing to the slightly-warped conditions of the boards the meeting edges thereof may be situated at a slightly-lower level than the surface at the center of the board. Under such circumstances it is impossible to use the ordinary plane to smooth up the meeting edges of the boards, because the sole of the plane by resting upon the higher portions of the boards either side of the meeting -edges of adjacent boards lifts the cutting edge of the plane out of contact with the said meeting edges on which it is desired to operate. Accordingly heretofore the joints between adjacent floor-boards have usually been finished by hand by means of a scraper, a tedious and slow operation. This operation can be accomplished with my improved plane, for since the cutting edge is situated some distance below the sole of the plane the joints between the boards may be operated upon even though the boards are warped slightly.

My improvement consists in providing the plane, of whatever description, with a gage-rib which extends across the sole thereof adjacent the mouth through which the cutting edge of the plane-iron projects. Preferably this gage-rib will be constructed to be detachably secured to the plane, so that the plane can be used with or without it, as desired.

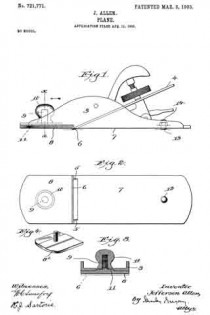

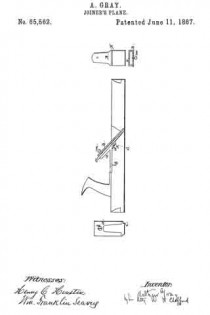

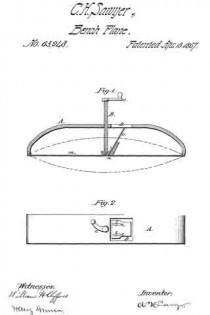

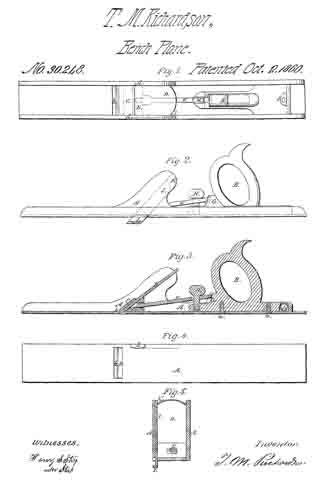

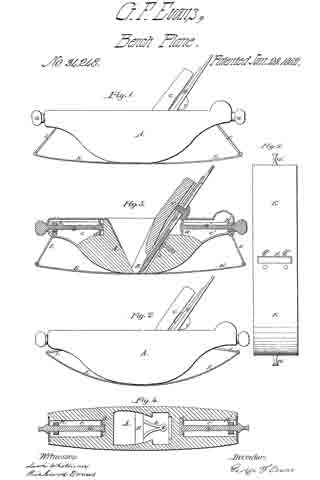

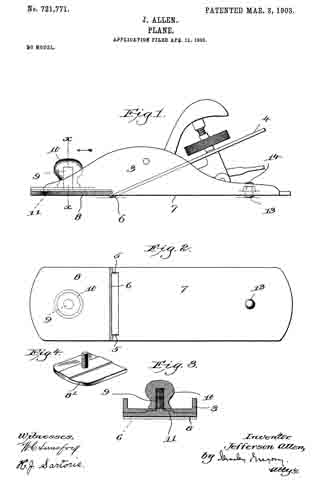

Referring to the drawings, Figure 1 is a side elevation of a plane embodying my improvements. Fig. 2 is a bottom plan view thereof. Fig. 3 is a section on the line x x, Fig. 1, looking in the direction of the arrow, and Fig. 4 is a detail to be hereinafter referred to.

My improvement is of such a character that it may be applied to any type of plane, and in the drawings 3 designates the stock of one common type of plane, and 4 is the plane-iron. These parts may be of any usual construction.

Extending across the sole of the plane and adjacent the mouth 5, through which the cutting edge of the plane-iron projects, and preferably in front of the said mouth, is a gage-rib 6, upon which the plane is adapted to rest.

The cutting edge of the plane-iron will be adjusted so that its cutting edge is sufficiently below the gage-rib to perform the cutting or planing operation, and when in use the gage-rib serves to lift or carry the sole 7 of the plane above the surface being operated upon, which surface is designated by the dotted line in Fig. 1.

By turning the plane at an angle to the direction of movement thereof during the planing operation the width of the shaving cut from the surface may be regulated, and since the sole of the plane is above the level of the surface being operated upon it is possible to plane or smooth the depressed portions in the surface and also to smooth up the joint between adjacent boards even though the boards may be warped more or less.

In order that my invention may be applied to different planes, I prefer to detachably secure the rib 6 to the stock of the plane, so that the rib may be removed and the plane used in an ordinary way, if desired. Accordingly I have herein illustrated said rib as being formed integral with a nose-piece 8, which is detachably secured to the front end of the plane, whereby said nose-plate and rib may be removed whenever it is desired to use the plane in the ordinary way. Any suitable or appropriate means may be employed to detachably secure said nose-piece to the stock, and for convenience I have herein illustrated said nose-piece as being provided with a screw-threaded stem 9, which projects through an aperture in the stock and on which a clamping-nut 10 in the form of a handle or knob may be screwed.

I will preferably provide the nose-piece with the positioning-rib 11, which is received in a suitable groove in the stock. I will preferably furnish each plane with a second nose-piece 8′, which is similar to the nose-piece 8 except that it has no rib 6 thereon, said second nose-piece being of a thickness so that when in position its lower surface is in the plane of the stock 7. By using either of the nose-pieces the plane may be used either as an ordinary plane or may be provided with my improvements, as desired. I will also preferably provide the heel of the plane with a detachable half round or semispherical projection 13 to form a sort of rocking support for the plane when my improvements are applied thereto. This rocking support provides means whereby the plane may be regulated slightly to better accommodate it to uneven surfaces. This projection 13 may be detachably secured to the stock in any suitable way, and I have herein shown the same as provided with a screw-threaded stem passing through the stock and on which a clamping-nut 14 is screwed. If desired, however, the nose-piece 8 and the rocking support 13 may be secured in position by screws passing through the same and into the stock.

My invention would also include a plane in which the rib (5 were made integral with the stock instead of upon a separate nose-piece which may be detachably secured thereto. In such a construction, however, the plane could not be converted into an ordinary plane.

Believing that I am the first to provide a plane having the gage-rib extending transversely across the sole thereof, I desire to claim the same broadly and would consider as coming within my invention any plane having this feature however the said rib may be secured to the stock.

Having described my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. In a plane, a stock having a rib extending transversely of the sole adjacent the cutting edge of the plane-iron.

2. In a plane, a stock having a rib detachably secured to and extending transversely of the sole adjacent the cutting edge of the plane-iron.

3. In a plane, a stock, a plane-iron, a nose-piece detachably secured to the front of said stock, said nose-piece having a gage-rib extending below the plane of the sole of the stock.

4. In a plane, a stock having a gage-rib extending transversely of the sole thereof and adjacent the mouth.

5. In a plane, a stock having a gage-rib extending transversely across the sole adjacent the mouth and a rounding projection extending from the sole of the plane at the back end thereof.

6. In a plane, a stock, a nose-piece detachably secured thereto, said nose-piece having a gage-rib extending across the sole of the stock, and a rounding projection secured to the sole of the stock at the back end thereof.

7. A plane having a gage-rib projecting from the sole thereof adjacent the mouth and serving to raise the sole of the plane above the cutting edge of the iron.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

JEFFERSON ALLEN.

Witnesses:

D. W. DEEDLER,

O. L. WELLS.