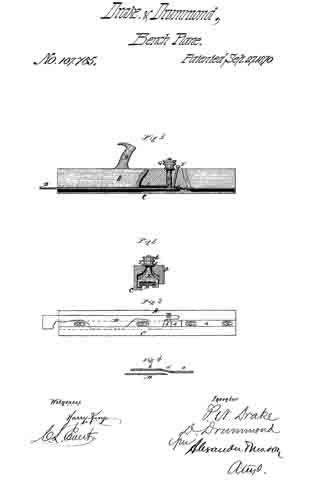

No. 96,258 – Improvement In Carpenters’ Planes (Georg Müller) (1869)

UNITED STATES PATENT OFFICE.

_________________

GEORG MÜLLER, OF NEW YORK, N. Y., ASSIGNOR TO HIMSELF AND FRANCIS BURNET, OF SAME PLACE.

IMPROVEMENT IN CARPENTERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 96,258, dated October 26, 1869.

_________________

To all whom it may concern:

Be it known that I, GEORG MÜLLER, of the city, county, and State of New York, have invented a new and useful Improvement in Carpenters’ Planes; and I do hereby declare that the following is a full and exact description of the construction and operation of the same, reference being had to the accompanying drawings, making part of this specification, in which —

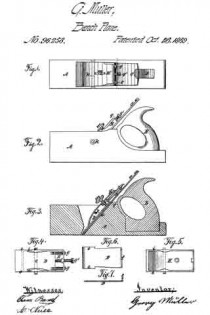

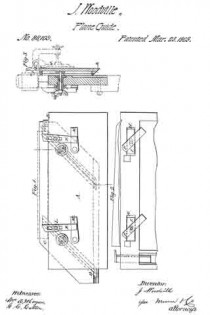

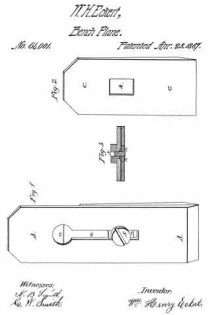

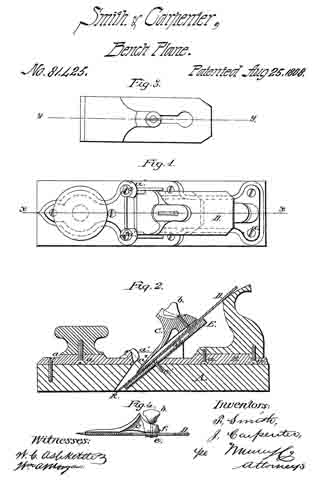

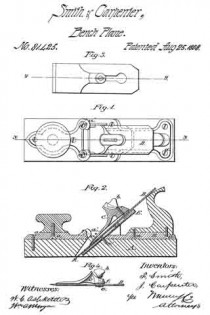

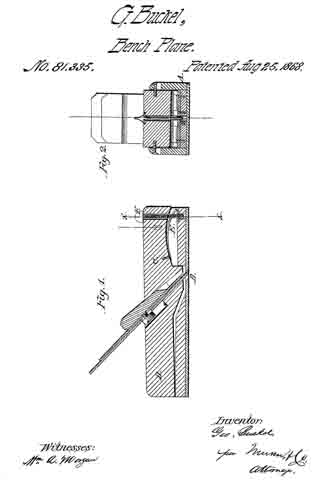

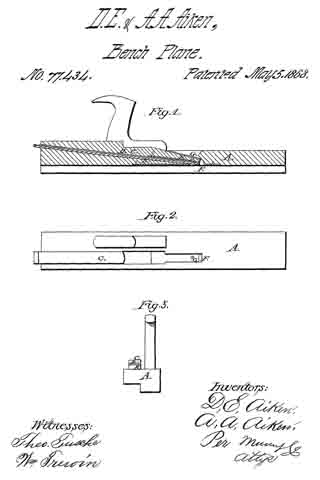

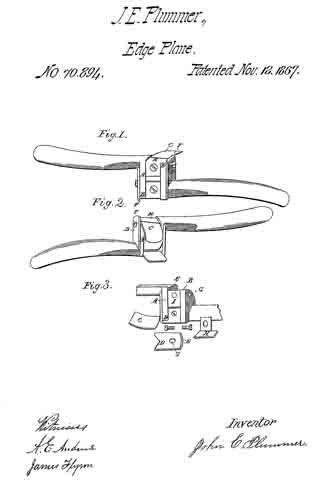

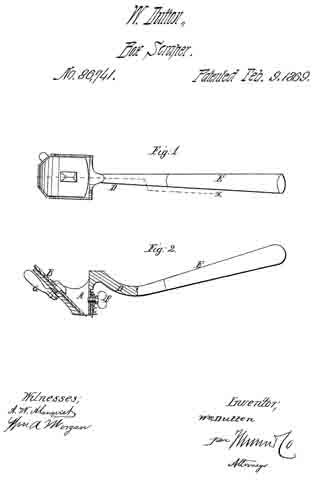

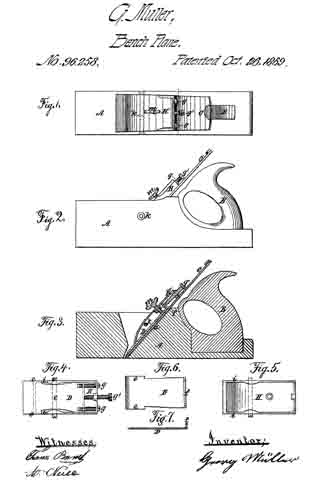

Figure 1 is a top view ofi a carpenter’s plane containing my invention; Fig. 2, a side elevation, and Fig. 3 a vertical section, of same. Fig. 4 is an under side view of the retaining-box in connection with the sliding cap-iron; Fig. 5, an inner view of retaining-box with cap-iron removed; Fig. 6, a plan of the sliding cap-iron, and Fig. 7 a longitudinal section of said iron.

This invention relates to a novel device for adjusting the cap and bit-irons of a carpenter’s plane in relation to each other and to the plane, and holding the same firmly in position by means of a swinging box or frame, which is pivoted to the plane-stock, and on which the cap-iron slides, the said box having set-screws for adjusting, retaining, and bracing the box, cap-iron, bit-iron, and plane-stock together, and at the same time rendering the cutting-irons capable ofthe nicest adjustment and stability in relation to each other and to the face of the plane-stock.

Having described the nature of my invention, I will now describe its construction and mode of operation.

In the drawings, A is the plane-stock, B the handle, and C the plane-iron or cutting-bit. D is the cap-iron, having projections e e, which slide on the ways of the box, and having, also, a lip or projection, f, at right angles to its face, in which set-screws (which pass through the end of the box marked g g g’) operate, for purposes hereinafter explained. H is the retaining-box, which receives the cap-iron D, and has ways i i, on which the projections e e of the cap-iron slide, while the projection or lip f of said cap-iron slides on the interior of the box, Fig. 4. This box H is pivoted to the plane-stock at k, and has a clamping-screw, m, for the purpose of bracing the cap and bit irons together, and against the rear, a, of the throat of the plane-stock.

To arrange my plane for operation, I place the bit C in the throat a of the plane-stock. I next set the cap-iron D within the box H and insert the adjusting and clamp screws in their places, and I place the box so equipped in the throat of the plane. I now pass the pivot k through the throat of the plane, and through the box H; and for adjustment of the cap-iron in relation to the bit-iron in a longitudinal or transverse direction I simply turn the screws g g, or either of them, (as the case may be,) back or forth, and when so adjusted hold the cap-iron D in position by the screw g’, abutting against the lip f of the cap-iron, and I next clamp the whole together by means of the screw m, when my improved plane is ready for operation.

It will be seen from the above that by means of the pivot k and clamping-screw m the box H, cap-iron D, and bit-iron C are braced firmly together and against the plane-stock, equally distributing the pressure over the surface of the part a of the throat of the plane: Furthermore, by this arrangement the box H closely tits the throat of the plane laterally, the movements of the cap-iron being pertormed within the box; besides, the box can be brought near the mouth of the plane, thereby giving strength and stability to the cutting-irons, and at the same time easy exit to the shavings, for the reason that I dispense with the prize fork or carrier F, used in the subject of a patent granted me on the 29th day of May, A. D. 1866, and on which I consider my present invention an improvement, inasmuch as the swell on the box E, for reception of the prize-fork, prevented the approach of the box toward the mouth of the plane or end of the cutting-irons, rendering the said irons partially unstable, while it also prevented the easy exit of the shavings, or rather tended to choke the throat of the plane; and, besides this, the said box E was slotted for reception of the joint-pin G, and did not fill the throat of the plane laterally, as provision had to be made for the lateral movements of the cap-iron, and both the box and prize-fork were slid together, while in my present improvement the box H is stationary, while the cap-iron D slides transversely and longitudinally on the ways of the box; and thus I produce an improvement on my former plane, which can be manufactured for two-thirds of its cost.

What I claim as my invention, and desire to secure by Letters Patents, is —

The arrangement of the stationary box H, pivoted to the plane-stock, and fitting closely the the throat thereof laterally, in combination with the cap-iron D, which is moved and adjusted beneath the said box, substantially as and for the purpose herein specified.

In testimony whereof I have hereunto set my signature this 21st day of August, A. D 1867.

GEORG MÜLLER

Witnesses:

FRANZ BERNET;

A. NEILL.