No. 46,614 – Improvement In Bench Planes (Wing H. Taber) (1865)

UNITED STATES PATENT OFFICE.

_________________

WING H. TABER, OF LOWELL, MASSACHUSETTS, ASSIGNEE TO HIMSELF AND THOMAS H. ABBOTT, OF SAME PLACE.

IMPROVEMENT lN BENCH-PLANES.

_________________

Specification forming part of Letters Patent No. 46,614, dated February 28, 1865.

_________________

To all whom it may concern:

Be it known that I, WING H. TABER, of Lowell, in the county of Middlesex and State of Massachusetts, have invented a new and useful Improvement in Bench-Planes; and I do hereby declare the same to be fully described in the following specification and represented in the accompanying drawings, of which —

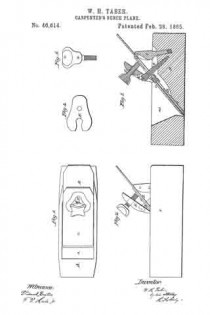

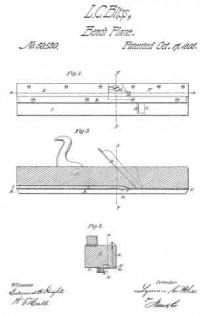

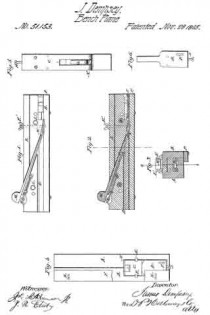

Figure 1 is a top view, Fig. 2 a side elevation, and Fig. 3 a longitudinal section, of a bench-plane provided with my invention. Flg. 4 is a top view of the furcated lever of the mechanism for fastening the plane-iron in place in the stock and on the adjustable bed. Fig. 5 is a front view of the said adjustable bed.

The nature of my invention or improvement consists in the combination as well as in the arrangement of an adjustable bed, and a mechanism, as hereinafter described, for fastening the plane iron in place in the stock and on the said bed, the parts of the said combination being arranged as hereinafter described, and the object or purpose of such invention being to enable the slant or inclination of the plane-iron to be varied in order to vary the width or size of the shaving-mouth at the cutting edge of the plane iron, and thus adapt the plane to the cutting of either thick or thin shavings from a piece of wood or article while being planed.

In the drawings, A denotes the plane-stock, provided with a throat, a, and a plane-iron, B, the latter having a cap iron or plate, C.

The plane iron rests on the lower part, b, of the throat a, and also on an adjustable bearing or bed, G, which is formed as shown in Figs. 3 and 5, screws into the stock, and is arranged in an inclined position, as exhibited in Fig. 3.

By taking hold of the head c of the bed or bearing G, and revolving the bearing, we can either screw it more of less into the stock, so as to vary the distance of the top of the head from the upper surface of the stock.

In advance of the bearing G there is a screw, D, which goes through the plane-iron and its cap-iron, and is screwed into the stock. A forked lever, E, clasps the shank of the screw D, and directly underneath the head d thereof, and has a screw, F, screwed through it and against the cap-iron G, the lower end of the said lever E being in contact with the cap-iron.

The adjustable fulcrum-screw D, the furcated lever E, and the screw F, constitute the mechanism for fastening the plane-iron in the stock or in the latter and to the bearing G. This fastening mechanism I do not claim as my invention by itself, or irrespective of the adjustable bearing G.

By the use of the said fastening mechanism no wedge is required to hold the plane in the stock. Consequently there will be no danger of splitting the stock, such as is incident to the wedge. The adjustable bearing G enables the shaving-mouth to be increased or diminished, as circumstances may require, and is also advantageous in other respects.

I lay no claim to the invention ofthe mechanism as above described for fastening the plane iron in the stock, such mechanism consisting of the screw D, the lever E, and the screw F, arranged with respect to the plane-stock and the plane iron or irons as described. Nor do I claim an adjustable bed as combined with stationary supports of the plane-iron, and constituting with them a means of confining the said plane-iron in its place in the stock, the same being as shown in Asahel G. Batchelder’s application for a patent filed in United States Patent Office on or about the 3d day of July, A. D. 1857, and subsequently rejected. My invention not only differs from those above cited as well in the structure as in the arrangement of its parts, but possesses one or more advantages not incident to them. In other words, while it retains all those of the fastening mechanism above mentioned, it has another which results from the adjustable bed not being required to be revolved in order to effect the fastening of the iron in the stock to be varied, such angle being for all practical purposes constant in the said Batchelder’s plane. I thus have the double advantage of not only varying the angle of inclination of the plane-iron, but of being capable of so springing the iron as to vary the breadth of the shaving-mouth of the throat as circumstances may require.

I claim —

1. The combination of the adjustable bed or bearing G, the screws F and D, and the lever E, the whole being arranged with respect to the plane-iron and the stock substantially as specifed.

2. The arrangement of the adjustable bed G, with the fulcrum-screw D, the lever E, the screw F, the plane-iron B, and its bearing b, arranged at the lower part of the throat a, as described.

WING H. TABER.

Witnesses:

J. N. MARSHALL,

JOEL A. ABBOTT.