No. 40,483 – Improvement In Planes For Beading And Molding (Seth C. Howes) (1863)

UNITED STATES PATENT OFFICE.

_________________

SETH C. HOWES, OF SOUTH CHATHAM, MASSACHUSETTS.

IMPROVEMENT IN PLANES FOR BEADING, MOLDING, &c.

_________________

Specification forming part of Letters Patent No. 40,483, dated November 3, 1863 ; antedated October 24, 1863.

_________________

To all whom it may concern:

Be it known that I, SETH C. HOWES, of South Chatham, in the county of Barnstable and State of Massachusetts, have invented a new and useful Improvement in Planes for Beading, Molding, &c., &c. ; and I do hereby declare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, making a part of this specification, in which —

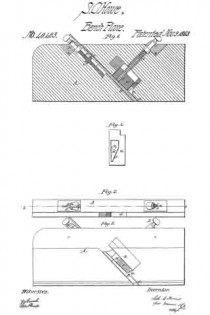

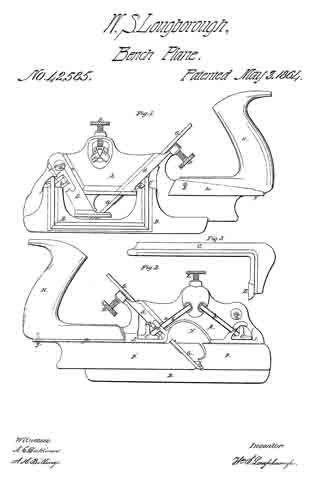

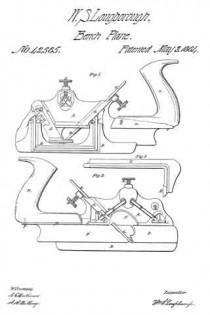

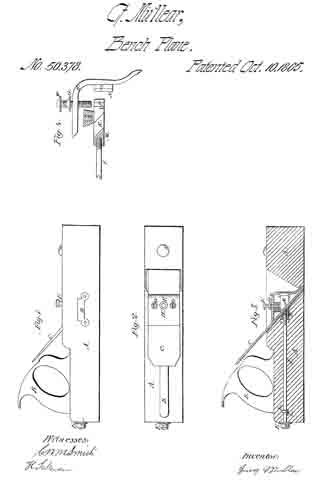

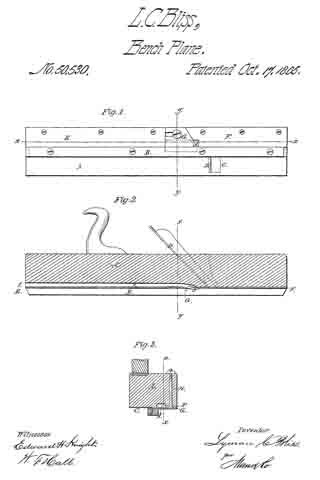

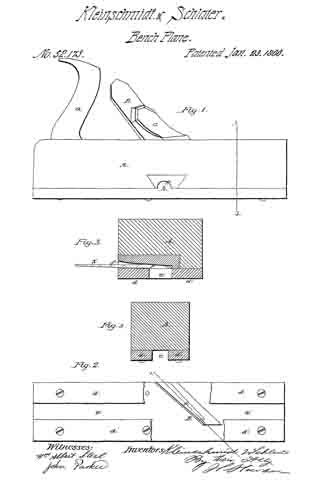

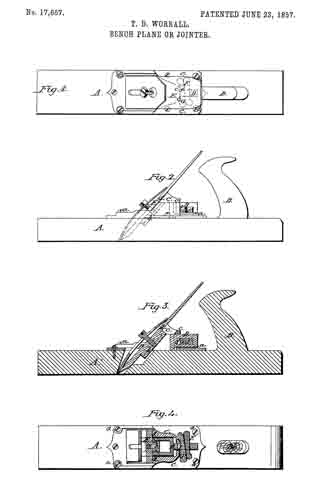

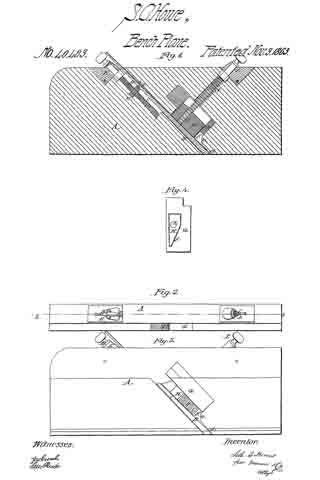

Figure 1 is a vertical section of my invention, taken in the line x x, Fig. 2; Fig. 2, a plan or top view of the same 5 Fig. 3, a side view of the same; Fig. 4, a detached face view of the clamp which holds the plane iron in proper position.

Similar letters of reference indicate corresponding parts in the several figures.

This invention relates to an improvement in that class of planes used by joiners for forming beads and moldings, and also for forming rabbets, and which discharge the shavings at the side of the stock.

The object of the invention is to obtain a plane of the kind specified which will discharge the shavings freely and without the liability of choking or clogging in the throat, and one also which will admit of the iron being adjusted with the greatest facility to regulate the depth of cut and admit of the iron being firmly secured in the stock.

To enable those skilled in the art to fully understand and construct my invention, I will proceed to describe it.

A represents the stock of the plane, which is constructed of wood, and of the usual form, and B is the “iron,” the lower end or cutting-edge of which is made of a form corresponding to that of the bead, molding, or rabbet to be cut. This iron has a notch, a, made in its back surface, near its upper end, and into this notch a projection or spur, b, on a nut, C, is fitted, said nut being in an inclined recess or groove, c, in the stock. The nut C is on a screw, D, the upper part of which is iitted in a metal socket, F, placed in a recess in the upper part ofthe stock. The upper part of the plane-iron is fitted in the front part of the recess or groove c, while the lower part passes through a recess, F, which is open at its side, and forms what is commonly termed the throat, to admit of the shavings out by the iron to pass out from the stock. This throat is narrow at its lower end, as shown at d, and it widens very gradually for a short distance upward, and then suddenly expands or increases in width, with a rounded front, e, as shown clearly in Figs 1 and 3.

Within this enlarged part of the throat there is fitted a metal socket or guide, G, in which a clamp, H, works. This clamp is also constructed of metal, and may be described as being formed of a rectangular bar, having one side beveled, as shown at f (See Fig. 4.) The clamp is allowed to work freely in the socket or guide G, and it is moved or operated by a screw, I, which works in an internal screw-thread, g, in the clamp, as shown in Fig. 1, and is litted in a metal socket, J, placed in a recess in the upper part of the stock. The portions of the screws I and D, which are htted in the sockets E and J, are smooth, (see Fig. 1,) and the beveled surface f is placed outward.

From the above description it will be seen that by turning the screw-rod D, the iron may be raised and lowered according to the depth of cut or thickness of shaving required, as by turning said screw the nut C is moved, and with it the iron, and when the desired set of the iron is obtained, the latter is secured in position by pressing the clamp H against it, the latter result being attained by turning the screw I. The back part of the iron is pressed by the clamp H firmly against the back part of the throat F.

In using the implement the shavings will readily pass up the lower narrow part of the throat, and in passing into the enlarged part they will turn freely the rounded corner e, and, coming in contact with the hard, smooth metal surfaces of the inner side of the socket or guide G, and the beveled surface f of the clamp H, are discharged freely from the throat, and all choking and clogging of the latter avoided.

The ordinary throats of this class of planes are very liable to choke or clog with shavings, as they have a comparatively long narrow opening at their lower parts, and are not provided with any rnetal surfaces, which have a tendency to prevent the sticking or adhering of the shavings in the throat.

Having thus described my invention, I claim, as an improved article of manufacture —

A molding-plane provided with the adjusting-nut C, screw D, the holding-clamp H, screw J , and curved throat e, all constructed and operating together, as herein shown and described.

SETH C. HOWES.

Witnesses:

JOHN G. DOANE,

FREEMAN E. CHASE.