No. 102,406 – Improvement In Plane-Stock (Julius Katz) (1870)

United States Patent Office.

JULIUS KATZ, OF CINCINNATI, OHIO.

Letters Patent No. 102,406, dated April 26, 1870.

_________________

IMPROVEMENT IN PLANE-STOCK.

_________________

The Schedule referred to in these Letters Patent and making part of the same.

_________________

To all whom it may concern:

I, JULIUS KATZ, of Cincinati, Hamilton county, Ohio, have invented a new and useful Improvement in Plane-Stocks, of which the following is a specification.

My invention relates to an improved facing device for wood-workers’ plane-stocks.

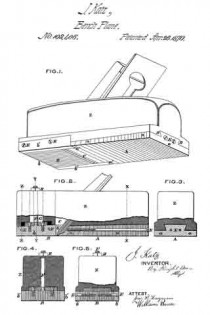

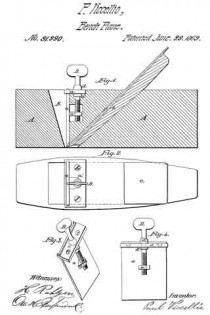

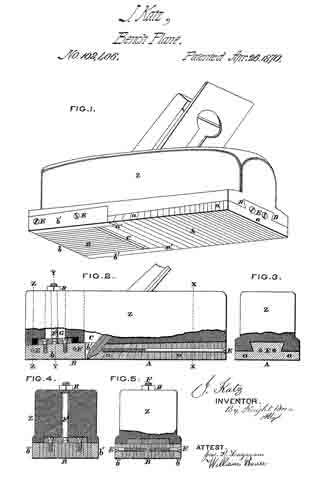

Figure 1 is a perspective under-side view of a plane-stock. embodying my improvement.

Figure 2 is a partly-sectionized side elevation thereof.

Figures 3, 4, and 5 are transverse sections at the lines X X, Y Y, Z Z, respectively.

I make the entire under surface of my improved plane-stock to consist of blocks or strips of bone, ivory, or similar hard organic substance, glued together in two pieces or slabs, A and B, of which the slab A, in rear of the throat C, fits, and occupies a dovetail excavation, D, on the under side of the wooden portion Z of the stock, to which it is firmly glued.

The component strips a and b of either slab are also firmly glued together, and additionally secured together by screws E.

The slab B, instead of being immovably fastened to the stock, is made capable of a slight longitudinal adjustment, and, for this purpose, is surmounted by a bolt or stern, F, which, extending upward through a slot, H, in the plane-stock, is secured by a nut, G, on the top of the stock.

Of the strips which compose the shiftable piece, B, the two outside ones, b’ b’, project rearward from the others, and enter jogs or gains a’ in the slab A.

I claim herein as new and of my invention —

Facing a plane-stock with a congeries of strips of bone or like substance, glued and screwed together and fastened to the stock proper in the manner set forth.

In testimony of which invention I hereunto set my hand.

JULIUS KATZ.

Witnesses:

GEO. H. KNIGHT,

JAMES H. LAYMAN.