No. 136,469 – Improvement In Carpenters’ Planes (Justus A. Traut) (1873)

UNITED STATES PATENT OFFICE.

_________________

JUSTUS A. TRAUT, OF NEW BRITAIN, CONNECTICUT.

IMPROVEMENT IN CARPENTERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 136,469, dated March 4, 1873.

_________________

To all whom it may concern:

Be it known that I, JUSTUS A. TRAUT, of New Britain, county of Hartfbrd and State of Connecticut, have invented certain new and useful Improvement in Carpenters’ Planes; and to enable others skilled in the art to make and use the same I will proceed to describe, referring to the drawing, in which the same letters indicate like parts in each of the figures.

The nature of this invention consists in making a metal tool combining plow, dado, and rabbet, capable of being easily and quickly changed and adjusted from one to the other.

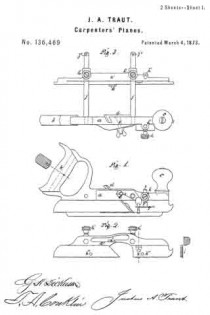

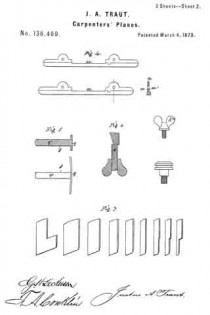

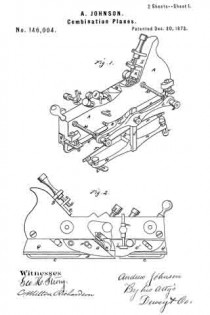

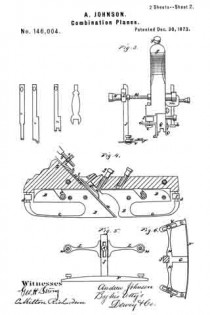

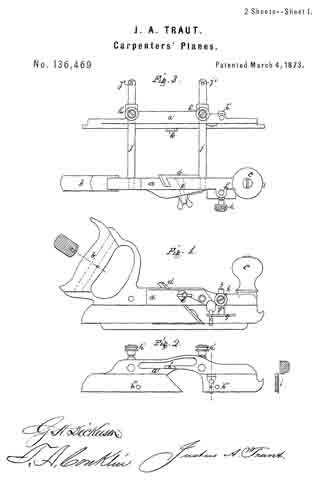

Figure 1 is an outside elevation of the stock, in which the cutting-tools are secured. Fig. 2 is an inside view of an adjustable section of the stock, which is fitted closely and works back and forth freely upon arms, which are secured in a detachable manner into the main stock. Fig. 3 is a top view of this tool, showing the detachable arms secured in the body of the stock, one portion of which is arranged thereon so as to move back and forth freely and parallel with the main body. Fig. 4 shows the sides and section of a guide-plate, having a rabbet on each side which takes bearing on the edge of and is secured to the outside of the adjustable section of the stock by screws; one side of this plate when secured will be flush with the inside face of the stock; when the other side of the plate is secured to the stock it will form a rabbet at the junction of the lower edge of the stock and face of the plate; when secured flush with the stock serves simply as a guide; when secured so as to form a rabbet, the lower edge of the stock and face ofthe plate will take bearing against the edge and surface of the material being worked. Fig. 5 is a gage device, arranged near the front end of the tool to regulate the depth of cut, adjusted and held at the desired point by a set-screw. Fig. 6 is a screw-bolt, fitted into a hole drilled through the stock to receive said bolt, and is couuterbored from the inside so as to just receive the head of said bolt; one side of said bolt-head is cutaway so as to form an incline plane parallel with the face of the cutting-tool, so that by turning the nut on said bolt the incline surface will compress the cutting-tool and hold it firmly in its place. Fig. 7 are cutting-tools much like those in common use.

a is the stock proper. a’ is an adjustable section of the stock. b is a handle, fitted and secured to the metal by glue, having an admixture of mineral or other suitable material to insure its being held more firmly; I also insert a rivet through the wood and metal. c is a knob, arranged at the front end of the stock a, by which to steady the tool. d is the cutting-tool, fitted to the stock in the usual way, and is pressed to its seat by the incline surface of the screw-bolt e. f is a gage to regulate the depth of the cut of the tool d, having a shoe, g, secured to an arm, g’, by which it is adjusted and held to its desired position by set-screw h. This gage f is fitted to the sockets h’ h’ in the two-part stock, so that it can be changed from one to the other as occasion may require. i i are spur-cutters, fitted into dovetail grooves in the outside surfaces, and near the lower edge of the two parts of the stock a a’, just in front of the cutters, for the purpose of cutting the fiber of the wood to prevent the cutter from tearing. j j are arms fitted into the body of the stock, so that they may be removed and replaced at pleasure simply by inserting a pin into the orifices j’ The adjustable section of the stock a’ is attached to the arms j j, to fit closely and move freely to and fro in its relative position with the stock a, and is secured by set-screws h h. k is a boss or projection formed on the inside of the adjustable section a’, Fig. 2, so that when a cutter is secured in the stock a, and the adjustable stock a’ is moved forward, the boss k will bear against the outer edge of the cutter, which will fix the spurs the exact distance apart as the cut of the tool, thus forming a dado variable in width with that of the cutter used, simply by changing one cutting-tool for another.

If it be desirable to use a rabbet-plane place the side m of the guard-plate n against the outside and lower edge of the plate of the stock a’, and secure it by the screws h”’ h”’, Fig. 2, which will allow the lower edges of the two-part stock a a’ to rest upon the surface of the material, while the face of the guard-plate it bears against the edge or sides of the material on which the rabbet is to be formed. Thus a perfect rabbet-plane is produced susceptible of being regulated to various widths and depth.

When it is desirable to use this tool for a plow place the side m’ of the guard-plate n against the stock-plate a’, flush with the inside thereof, and secure the same by set-screws h”’ h”’; then use in the common way. Thus I am enabled to produce a dado, plow, and rabbet-plane in one tool, quickly and easily changed from one to the other, made detachable, and which can be packed in a small compass.

What I claim, and desire to secure by Letters Patent, is —

1. The combination of the stationary stock a with the adjustable stock a’, when the latter is provided with the boss k, substantially as and for the purpose specified.

2. The detachable and reversible guard-plate n, when used in combination with the stock a, and adjustable stock a’, substantially as and for the purposes specified.

JUSTUS A. TRAUT.

Witnesses:

G. H. DICKERSON,

J. A. CONKLIN.