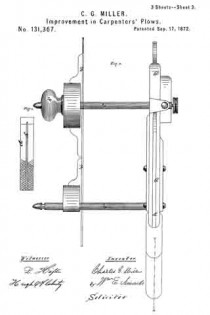

No. 129,508 – Improvement In Planes (Levi A. Alexander) (1872)

UNITED STATES PATENT OFFICE.

_________________

LEVI A. ALEXANDER, OF PITTSFIELD, MASSACHUSETTS.

IMPROVEMENT IN PLANES.

_________________

Specification forming part of Letters Patent No. 129,508, dated July 16, 1872.

_________________

To all whom it may concern:

Be it known that I, LEVI A. ALEXANDER, of Pittsfield, in the county of Berkshire and State of Massachusetts, have invented an Improvement in Planes, of which the following is a specification, reference being had to the accompanying drawing.

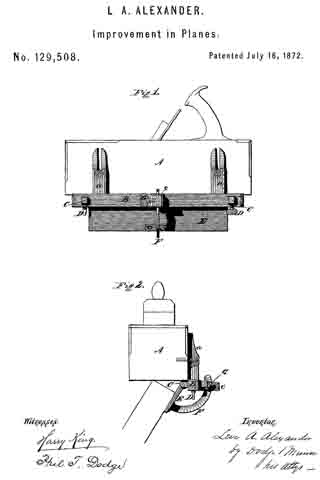

My invention consists in providing an edging-plane with an adjustable hinged guide by which the plane may be regulated so as to cut or plane the edge of the wood at any desired angle.

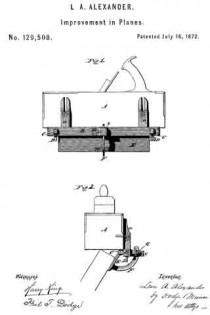

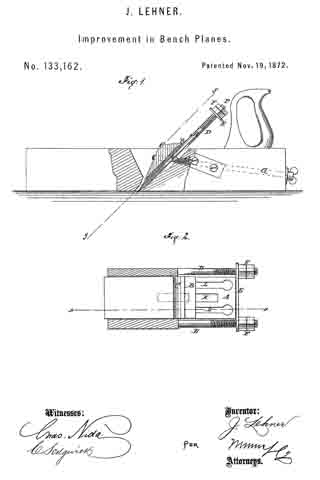

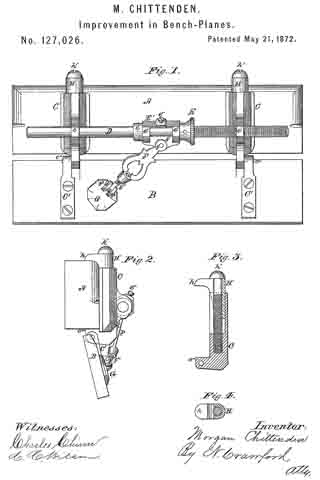

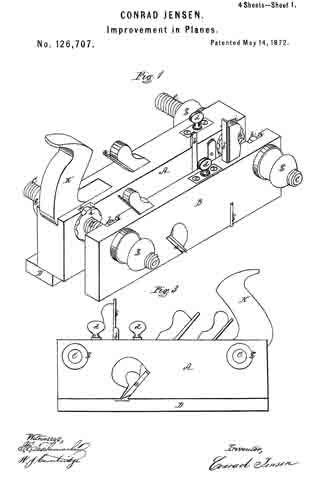

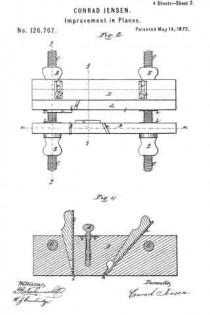

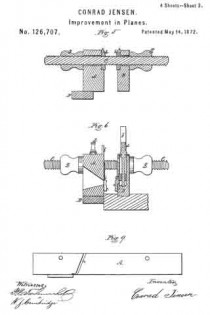

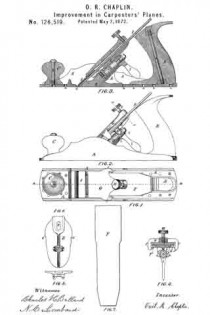

Figure 1 is a side view of a plane having my guide applied, and Fig. 2 an end view of the same.

A represents the plane, constructed in the ordinary manner, and B a long bar provided with arms at which are screwed to the side of the plane so as to hold the bar in place along its lower edge. In each end of the bar B there is mounted a transverse slide, C, and a thumb-screw, D, for fastening the same; and to the inner ends of these slides is hinged the guide E, consisting simply of a flat plate or bar. The guide, thus arranged, can be turned so as to present its face at any desired angle to that of the plane; and, to provide for holding it in the required position, it is provided with a curved arm, F, passing through a stud, c, on the bar B, and the stud provided with a thumb-screw, G, which may be set up against the curved arm so as to hold it firmly. To facilitate the adjustment of the guide at any particular angle, the curved arm F is provided with graduations properly numbered, so that it is only necessary to turn the guide until the proper graduation on the arm is brought in line with the stud c, and then to turn up the thumb-screw so as to fasten the arm. The guide may also be adjusted laterally on the face of the plane by loosening and moving the slides C.

In using the plane it is applied so that the face of the guide bears flatly against the side or face of the wood, so as to hold the face of the plane at the desired angle to the edge of the wood, as shown in Fig. 2, so that, upon operating the plane. it cuts the edge of the wood down to the exact bevel or inclination desired. The guide may, of course, be adjusted so as to cause the plane to cut the edge at a right angle to the face, instead of beveling.

By the use of the guide the trouble of constantly testing and fitting the edge by a hand-gauge in the usual manner is avoided and a perfectly true and even edge produced. The guide may be readily applied to any ordinary plane, and can be quickly removed when necessary.

Having described myinvention, what I claim is —

A guide for planes consisting of a plate, E, hinged by adjustable arms C to the bar B, the latter being provided with the arms a, with the graduated quadrant F, and the means for securing the same in place, all constructed and arranged to be applied to a plane, substantially as and for the purpose set forth.

LEVI A. ALEXANDER.

Witnesses:

LORENZO H. GAMWELL,

ELISABETH ALEXANDER.