No. 748,199 – Matching-Plane (Alexander Mason) (1903)

UNITED STATES PATENT OFFICE.

_________________

ALEXANDER MASON, OF SALEM, MASSACHUSETTS.

MATCHING-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 748,199, dated December 29, 1903.

Application filed March 20, 1903. Serial No. 148,745. (No model.)

_________________

To all whom it may concern:

Be it known that I, ALEXANDER MASON, a citizen of the United States, residing at Salem, in the county of Essex and State of Massachusetts, have invented certain new and useful Improvements in Matching-Planes; and I do hereby declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same.

This invention relates to matching-planes; and it consists in the novel construction and combination of the parts hereinafter fully described and claimed.

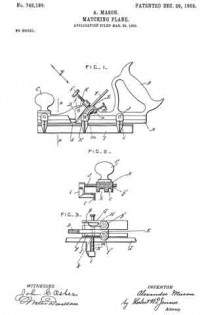

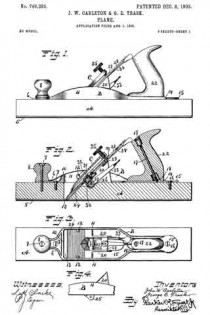

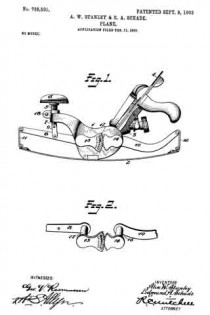

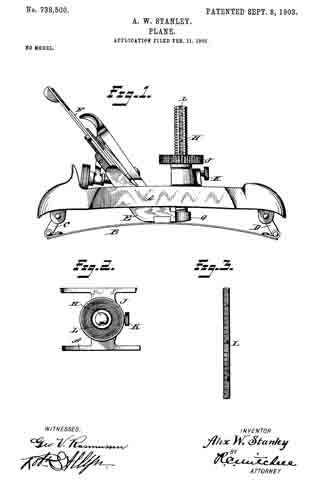

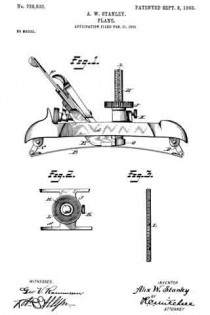

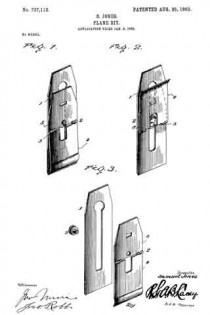

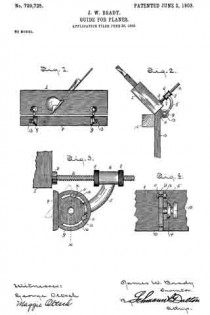

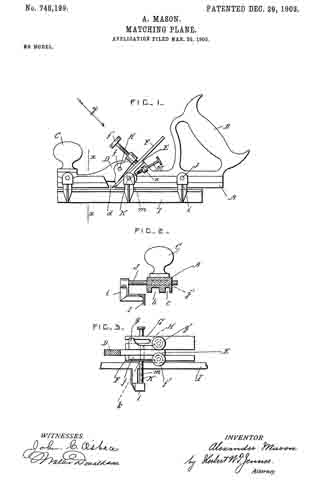

In the drawings, Figure 1 is a side view of the matching-plane. Fig. 2 is a cross-section taken on the line x x in Fig. 1. Fig. 3 is a partial plan view showing the clamping-levers and looking in the direction of the arrow y in Fig. 1.

A is the body of the plane, provided with a handle B at one end and a knob C at the other end. The body portion A has a broad groove b and a narrow groove c in its under side, and D is a longitudinal rib on the upper side of the body portion.

E is an inclined support for the blades, which also projects on the upper side of the body portion, and d represents slots or notches in the body portion A for the blades to project through.

F is a single cutting-blade, and G is a forked cutting-blade. These blades are laid upon the support E, one on each side of the rib D, and are clamped in position by means of two clamping-levers f and g, which are pivoted on the end portions of a pin H, which is secured in the rib D. These clamping-levers are provided at their upper ends with thumb-screws f’ and g’, which bear against the blades, so that the lower ends of the levers clamp the said blades securely in position.

I is a guide for the plane. This guide is provided with projecting brackets i at its end and middle portions. The end brackets carry bars J, which are slidable in guide-holes j in the body of the plane. The middle bracket carries a bar K, which is slidable in a hole k in the body of the plane and which is provided with a series of cross-holes m.

M is a spring-pressed stop-pin which is slidable in a lug n on the body of the plane and which engages with the said cross-holes. The guide is slid so as to suit the work, and it is then secured in position by means of the said stop-pin.

The two blades form three separate cutters, and they will tongue and groove boards of widely-varying thickness in a very satisfactory manner.

What I claim is —

In a matching-plane, the combination, with a body portion, of a guide for the said body portion provided with projecting brackets at its middle and end portions, bars projecting from the said end brackets and slidable in cross-holes in the said body portion, a bar projecting from the middle bracket and provided with a series of cross-holes and slidable in a hole in the said body portion, and a spring-actuated stop-pin carried by the said body portion and engaging with the cross-holes of the said bar.

In testimony whereof I affix my signature in presence of two witnesses.

ALEXANDER MASON.

Witnesses:

ALICE J. MURRAY,

FRED. K. DAGGETT.