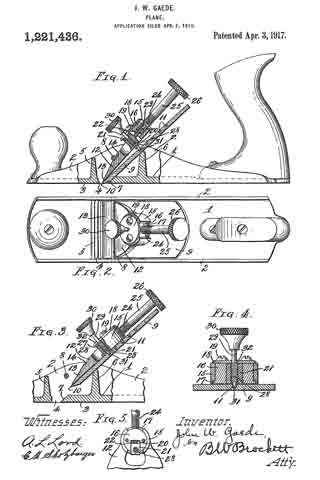

No. 1,221,436 – Plane (John W. Gaede) (1917)

UNITED STATES PATENT OFFICE.

_________________

JOHN W. GAEDE, OF CLEVELAND, OHIO.

PLANE.

_________________

1,221,436. Specification of Letters Patent. Patented Apr. 3, 1917.

Application filed April 7, 1915. Serial No. 19,824.

_________________

To all whom it may concern:

Be it known that T, JOHN W. GAEDE, a citizen of the United States, residing at Cleveland, in the county of Cuyahoga and State of Ohio, have invented certain new and useful Improvements in Planes, of which the following is a specification.

This invention relates generally to planes, and particularly to that class of such devices comprising a main body portion having the usual face provided with a throat, together with a bit and cap structure comprising a bit, a cap and clamping means carried by the cap and engaging in a suitable recess in the bit and arranged in a manner such that it may clamp the parts in place on the body portion on the one hand, and it may be released to free the cap and plate from the body portion but still maintain engagement between the two until these parts are removed entirely from the plane, the arrangement of these parts being such that when they are replaced in the plane the previous adjustment of the bit with respect to the cap and the body of the plane is not disturbed.

The invention may be further briefly summarized as consisting in the construction and combination of parts hereinafter set forth in the following description, drawings and claims.

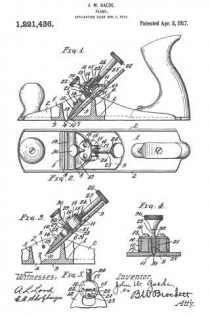

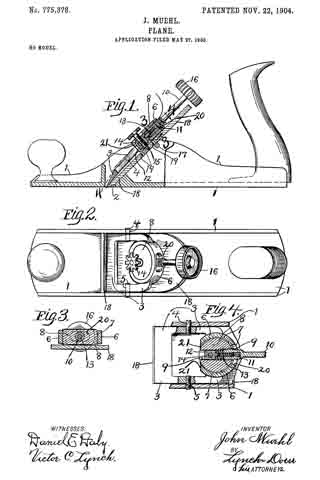

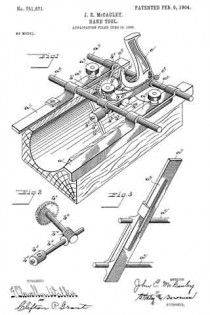

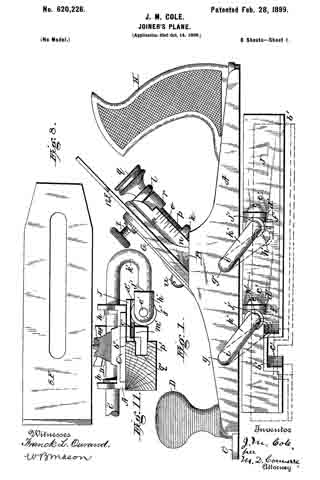

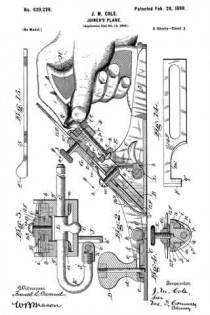

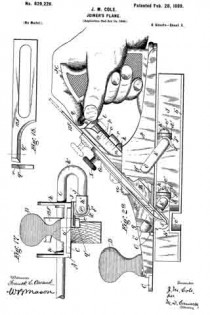

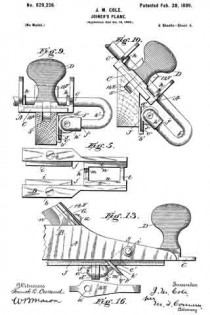

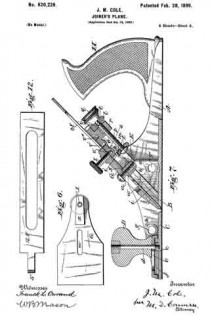

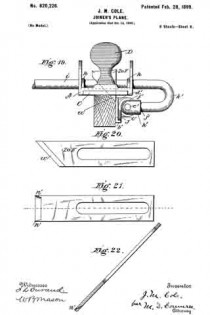

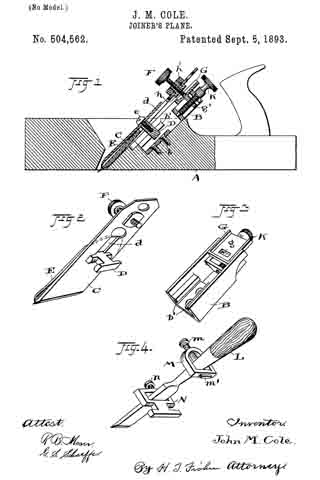

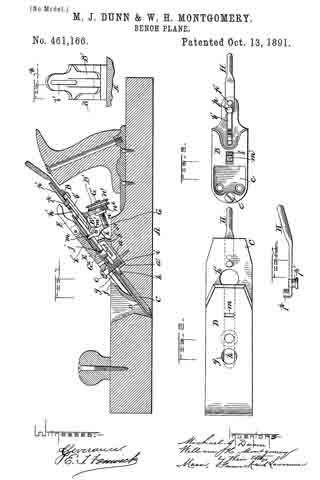

Referring to the drawings, Figure 1 is a side elevation of the plane broken away to show the bit and the adjacent parts in section; Fig. 2 is a top plan view; Fig. 3 is an enlarged sectional view showing the bit and cap partially removed; Fig. 4 is a cross sectional view showing the arrangement for holding the clamping screw in place; and Fig. 5 is a detail sectional view of the arc-shaped guides and cylindrical slide.

In carrying out the invention any preferred form and construction of parts may be employed so long as they possess the necessary characteristics, but I have shown one arrangement in the drawings, and in such embodiment the plane body comprises a base 1 having upwardly extending side flanges 2. The base 1 is provided with a smooth under-surface 3, and this surface is interrupted at the usual point by the throat opening 4. Just forward of this opening is an upwardly extending web 5 extending from one side flange 2 to the other and to the rear of this opening is another upwardly extending web 6 for a purpose to be described. The rear face 7 at the rear of the throat opening 4 is beveled as is usual in devices of this character. Extending from one side flange 2 to the other is a pin or rod 8 and it is between this rod and the upper edge of the web 6 that the bit and cap are located and clamped.

The bit 9 is provided with a cutting edge 10 and a longitudinally extending row of perforations 11 in its upper face. Above this bit 9 is the cap 12 provided with a tapered end portion 13 engaging on the top of the bit and having a transverse recess 14 for receiving the pin or rod 8. The cap is also provided at the back end with an upwardly extending cylindrical portion 15 which is out away at the rear, as shown in Fig. 2, and for a purpose which will be described. This cylindrical portion is also cut away at the front, thus forming two arc-shaped guides, and these guides receive a cylindrical block 16 which has a lower flange 17 for holding the block from moving upward through the arc-shaped guides. The block is held in place by an upper plate 18 secured thereto by screws 19. The cylindrical block 16 is slotted at 20 in a radial direction to receive a sliding block 21 which is provided with a threaded shank 22 engaging in a threaded opening 23 in the end of a screw shank 24 threaded into an opening in the cylindrical block 16, as is clearly shown in Fig. 1. This threaded shank 24 forms a part of an adjusting screw 25 provided with a knurled finger piece 26. The sliding block 21 is provided with an opening 27 for the reception of a shank 28 of a clamping screw 29 which is provided with a finger piece 30 at one end, and a tip 31 for engagement in the opening 11. The clamping screw 29 passes through a slot 32 in the plate 18, and this slot is less in width than the diameter of the threaded shank 28 so that when the plate 18 is in place the clamping screw may not be removed from the sliding block 21. It will be seen from the foregoing that when the clamping screw is forced downward with its tip in one of the recesses 11, the cap plate will be forced against the pin 8 and the bit will be forced against the upper edge of the web 6, with the result that the parts will be held firmly in place, it being possible, however, to adjust the bit by operating the adjusting screw 25 and to shift the plate laterally by swinging the adjusting screw from one side to the other, the block 16 turning in arc-shaped guides formed by the cylindrical portion 15.

It will also be noticed that when the bit and cap are to be removed, the clamping screw is released, and the cap and bit may be removed bodily and may be returned to position without the adjustment of the parts being affected.

Having described my invention, I claim:–

1. A plane having a bit support, an abutment opposite said support and forming therewith a seat, bit and cap members cooperating as a unit and lying in said seat, and bit and cap securing and interengaging devices carried by said unit for securing the unit in its seat and arranged to unpreventably maintain the assembled relation of the bit and cap while in their seat and until complete removal of the unit from said seat.

2. In a plane, a main body portion having a throat and a support for holding the bit member in its working plane, an abutment opposite said support and spaced therefrom, a bit member and a cap member lying in the space between the abutment and support, and means carried by said members for expanding them between the abutment and support in a direction normal to the plane of the bit and thereby securing them in place, said means being arranged to produce and unpreventably maintain interengaging relation between said members until removed together from said body portion.

3. A plane, comprising a body having a throated base, a bit support, and a rod opposite said support, a bit resting on said support and entering said throat and provided with a recess, a cap lying on said bit and having a seat to receive said rod, and a clamping screw carried by said cap and entering said recess, said screw when turned in one direction clamping the bit and cap in place, and means for preventing withdrawal of said screw from said recess while the bit and cap are in place in the body, whereby the bit and cap must be removed and inserted as a unit.

In testimony whereof I affix my signature in presence of two witnesses.

JOHN W. GAEDE.

Witnesses:

ALTON H. BEMIS,

A. L. LORD.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________