No. 848,364 – Multiple-Beading Plane (Paul Harding) (1907)

UNITED STATES PATENT OFFICE.

_________________

PAUL HARDING, OF LONG ISLAND CITY, NEW YORK.

MULTIPLE-BEADING PLANE.

_________________

848,364. Specification of Letters Patent. Patented March 26, 1907.

Application filed May 25, 1906. Serial No. 318,633.

_________________

To all whom it may concern:

Be it known that I, PAUL HARDING, a citizen of the United States, and residing at Long Island City, in the county of Queens and State of New York, have invented certain new and useful Improvements in Multiple-Beading Planes, of which the following is a specification, such as will enable those skilled in the art to which it appertains to make and use the same.

This invention relates to hand-planes for use by carpenters in beading moldings or other woodwork; and the object thereof is to provide an improved device of this class having a plurality of beads of different styles or dimensions, whereby a single plane of the class specified may be used for making a variety of beads or a variety of moldings or for producing a variety of beads in woodwork of any kind or class.

The invention is fully disclosed in the following specification, of which the accompanying drawings form a part, in which the separate parts of my improvement are designated by suitable reference characters in each of the views, and in which —

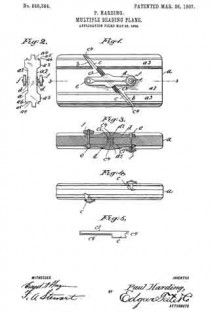

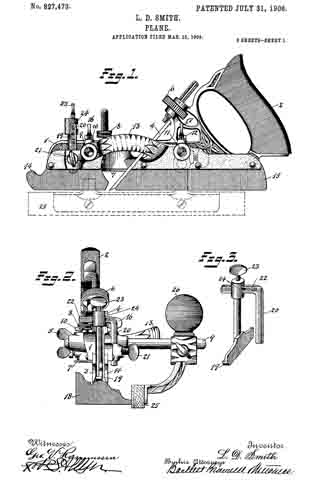

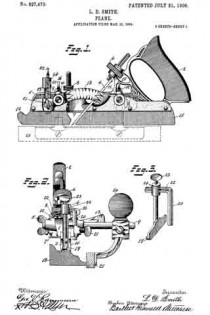

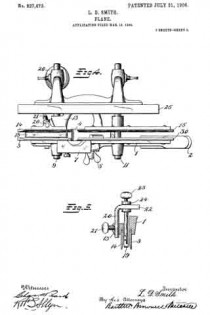

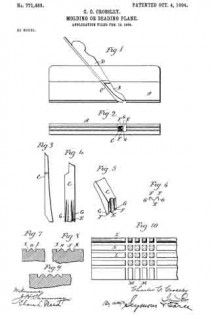

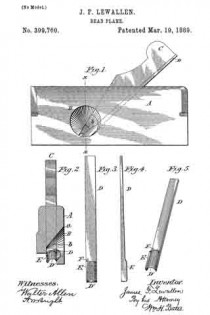

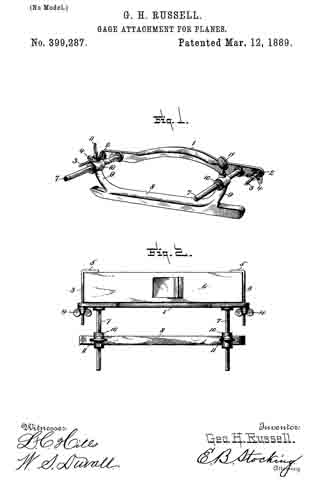

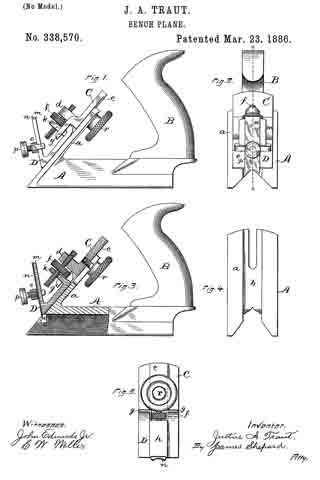

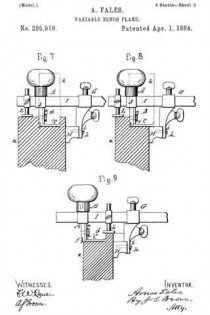

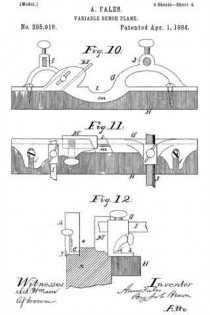

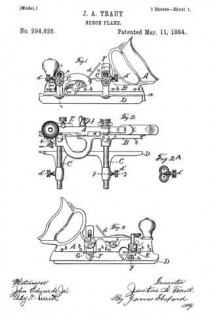

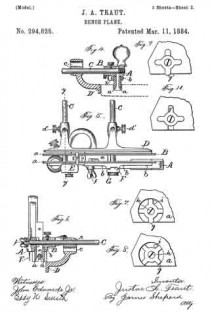

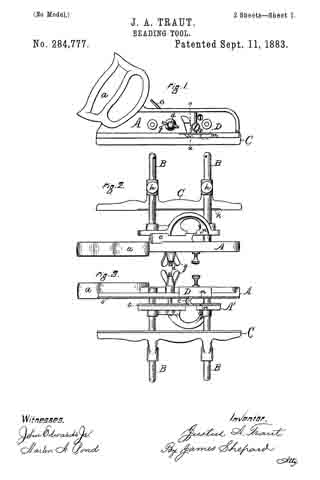

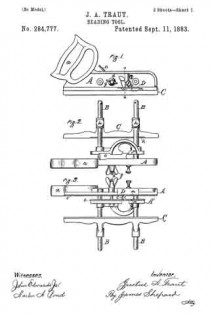

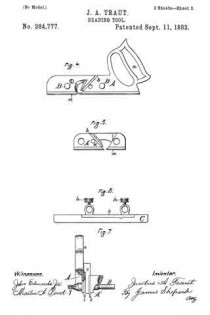

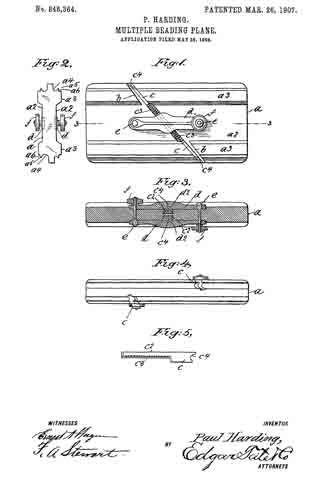

Figure 1 is a side view of my improved beading-plane; Fig. 2, an end view thereof; Fig. 3, a longitudinal section on the line 3 3 of Fig. 1; Fig. 4, a plan view, and Fig. 5 a side view, of one of the bits which I employ.

In the practice of my invention I provide an oblong flat block a, which constitutes the body of the plane, and said block is provided in the opposite side thereof with longitudinal wide grooves or spaces a2, whereby top and bottom thickened portions a3 are formed, said thickened top and bottom portions a3 being provided in their outer longitudinal faces with grooves a4, which are circular in cross-section, beads a5, and rabbet-grooves a6.

The block a, is provided in the opposite sides thereof and diagonally of the central portion thereof with grooves b, which extend through the thickened top and bottom portions a3 and also through the central portion of said block and in which are mounted bits c, two of which are placed in each side of the block, four bits in all being employed.

The bits c are provided with shanks c2, which overlap and extend across the central or body portion of the block and are provided in their outer sides with transverse grooves or recesses c3, forming corresponding teeth, and in the opposite sides of the body portion of the block are placed countersunk plates d, which are held in place by bolts e, provided at one end with thumb-and-finger nuts f, and the shanks c2 of the bits c are beveled on the sides in which the recesses are formed, and when two of said shanks are placed together in the opposite sides of the block they form a projecting longitudinal rib, as shown at c4, and the plates d are provided with corresponding transverse diagonal grooves d2, and in this way the bits c may be securely locked in the block a. As shown, the bolts e are preferably passed through the plates d and the central portion of the block a in opposite directions; but the placing of said bolts in this position is not absolutely necessary, and the thumb-and-finger nuts f may both be on the same side of the block a, if desired. In order to adjust the bits c, the thumb-and-finger nuts f or one of them is loosened and a suitable tool is inserted into the recess c3 of the shanks of said bits, and said bits are moved or adjusted to any desired extent, after which the thumb-and-finger nut or nuts are tightened, so as to hold the bits in the desired position.

In the drawings forming part of this specification the bits c are all of the same style, and the cutting edges c4 thereof are all of the same form, but of different dimensions, and the beads and grooves formed by means of my improved beading-plane, as shown and described, will all be of the same style, but will vary in transverse dimensions, the shape in cross-section of said beads being indicated by the shape of the beads and grooves a4, a5, and a6 shown in Fig. 2. It will be apparent, however, that the cutting edges of the bits may be of any desired form or shape, and the grooves and beads a4, a5, and a6 shown in Fig. 2 will vary to correspond therewith, and the beads and grooves formed by the plane will depend upon the style of these features of the construction.

Having fully described my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. A beading-plane comprising an oblong flat body member having longitudinal grooves and beads in the top and bottom thereof, and two bits mounted in the opposite sides of said member and diagonally thereof and in diagonal grooves formed therein, the cutting edges of said bits extending in opposite directions, and means for locking said bits in position, consisting of plates bolted longitudinally of the opposite sides of said body member and ranging transversely of the shanks of said bits.

2. A beading-plane comprising an oblong flat body member having grooves arranged diagonally in the opposite side portions thereof and extending through the top and bottoin faces thereof, two bits: mounted in the grooves in said opposite side portions of said ineniber and provided with overlapping shanks and the cutting edges of which extend in opposite directions, and means for locking said bits in position, consisting of plates secured longitudinally of the central body portion and in the opposite sides of said member transversely of the shanks of said bits.

In testimony that I claim the foregoing as my invention I have signed my name in presence of the subscribing witnesses.

PAUL HARDING.

Witnesses:

JAMES McMAHON,

WALTER D. WARD.