No. 1,399,631 – Plane-Scraper (Charles J. Lofdahl And Carl A. Lofdahl) (1921)

UNITED STATES PATENT OFFICE.

_________________

CHARLES J. LOFDAHL AND CARL A. LOFDAHL, OF JOLIET, ILLINOIS.

PLANE-SCRAPER.

_________________

1,399,631. Specification of Letters Patent. Patented Dec. 6, 1921.

Application filed December 27, 1919. Serial No. 347,754.

_________________

To all whom it may concern:

Be it known that we, CHARLES J. LOFDAHL and CARL A. LOFDAHL, citizens of the United States, residing at Joliet, in the county of Will and State of lllinois, have invented certain new and useful lrnprovenients in Plane-Scrapers, and we do hereby declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to rnake and use the same.

This invention relates to certain new and useful improvements in a plane scraper and has for its primary object the provision of a device of this character which will be constructed in such rnanner that the blade may be readily adjusted at various angles and securely held in position.

Another object of the invention resides in the provision of a plane scraper of the above stated character which will be constructed so that the blade rnay be readily adusted to present a new edge when required, without the necessity of removing the blade and sharpening the same.

A further object of the invention resides in the provision of a wood scraper provided with an adjustable blade carriage in which the blade may be securely held against chattering thereby making it possible to obtain a much smoother dressed surface.

A further object of the invention resides in the provision of a wood working tool of the above stated character which may be readily employed by carpenters, cabinetmakers and other workmen and which will be light in weight, easy to operate and composed of the minimum number of parts.

With the foregoing and other objects in view as will appear as the description proceeds, the invention consists in the novel combination, arrangement and cooperation of parts as hereinafter more specifically set forth, claimed and shown in the drawings in which:

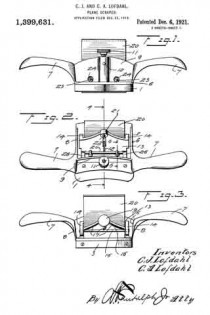

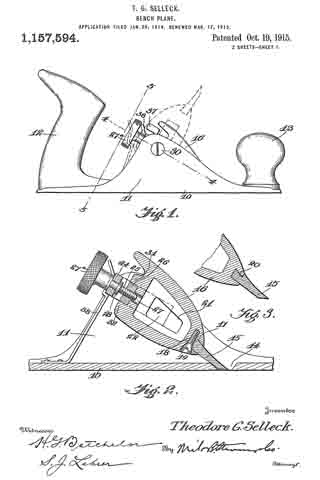

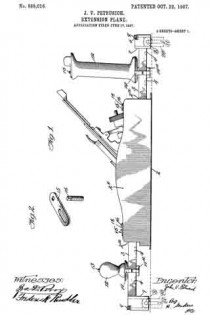

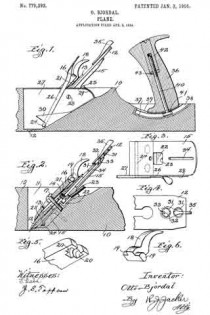

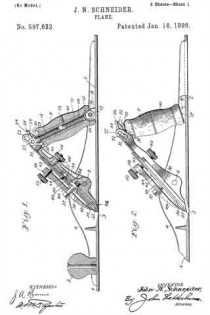

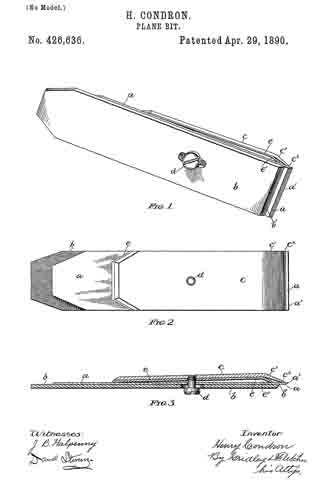

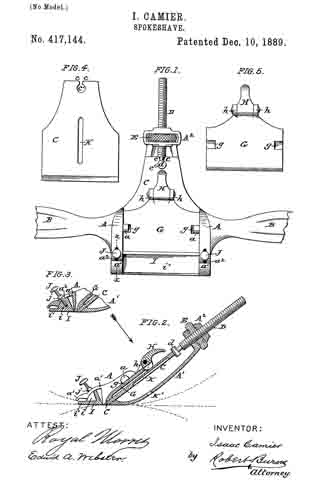

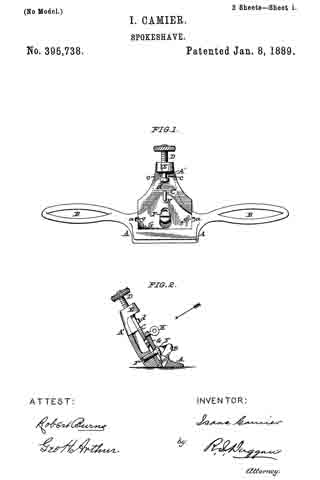

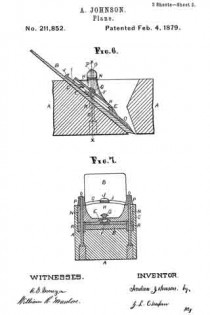

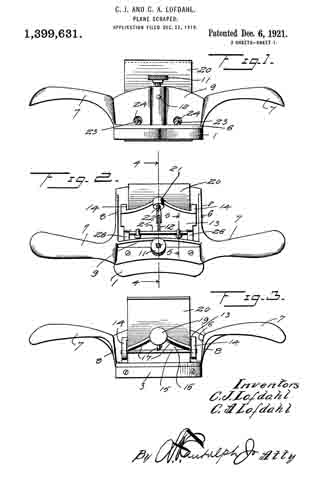

Figure 1 is a front elevation of the plane scraper.

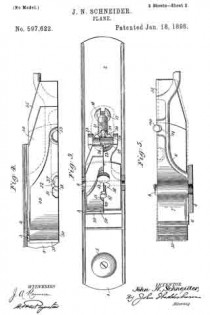

Fig. 2 is a top plan view thereof.

Fig. 3 is a rear elevation.

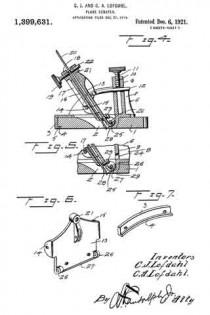

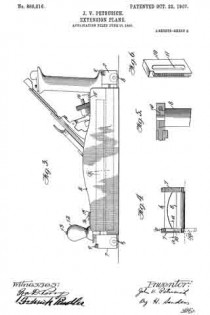

Fig. 4 is a verticle section on the plane of line 4–4 of Fig. 2.

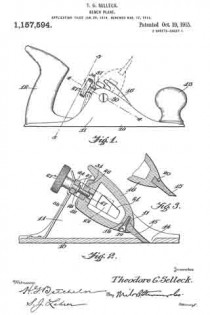

Fig. 5 is a vertical section on the plane of line 5–5 of Fig. 2.

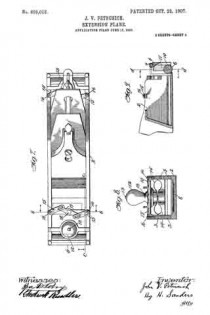

Fig. 6 is a detail perspective of the blade carriage removed, and

Fig. 7 is a detail perspective of the nose cap, removed.

Referring more in detail to the drawings, in which sirnilar reference characters designate corresponding parts throughout the several views, 1 designates the wood bottom having the blade opening 2 formed therein and a nose cap 3 secured upon its rear edge, said nose cap 3 being preferably forrned of metal and having an inturned lower flange 4 resting in the seat 5 formed therefor in the wood bottom, with the lower face of the flange 4 flush with the lower face of the wood bottorn 1, as will be clearly understood by reference to the drawings.

The metallic frame 6 is mounted upon the upper face of the wood bottom 1 and has a pair of oppositely extended curved hand grips 7 projecting from the opposite sides of the frarne 6, it being understood that the frame includes upwardly extended. side members 8 from vvhich the handles 7, extend at the forward corners of said members 6.

The frame also includes a front upstanding rnernber 9 with a central socket 10 formed on the outer face thereof and withln which is threaded a set screw 11, the lower end of which is adapted for binding engagement with the adjusting pin 12, which latter is pivoted to the front plate 13 of the blade carriage, said adjusting pin 12 having sliding movement through the front blade 9 and socket 10 in order that the blade carriage may be readily adjusted at any inclined angle desired.

The front plate 13 of the blade carriage has rearwardly extending ears 14 curved by its side portions and through which are extended the opposite ends of a locking rod 15 having binding engagement with the outer or rear face of the back plate 16 of the blade carriage, downward movement of the back plate 16 being limited by the flanges 17 formed on the diverging upper portions of the sides of said back plate 16 and which flanges also serve to reinforce or strengthen the back plate. This back plate 16 has a threaded ear 18 in its uppermost central portion and through which extends the shank of the set screw 19 for engagernent with the rear face of the blade 20 positioned between the front plate 13 and back plate 16 to assist in retaining the plate 20 in proper position within the carriage. The front plate 13 also has an uppermost central portion with a threaded ear 21 opposite the ear 18 of the back plate 15 with a bearing screw 22 adjustably positioned therein to engage the blade 20 at a point practically opposite the portion of the rear face of the blade 20 engaged by the set screw 19. The front plate 13 of the blade carriage also has a pair of lower bearing screws 23 adjustably mounted therein for proper bearing engagement with the front face of the blade 20 near the bottom of the blade carriage to cooperate with the bearing screw 22 when the three bearing screws are properly positioned to prevent chattering of the blade 20 during the use of the tool particularly when the tool is moving on its return stroke previous to another operative or cutting movement of the tool over the work. ln order that the lower bearing screws 23 may be readily adjusted when required, without the necessity of removing the tool carriage, the upstanding front member 9 is provided with a pair of spaced openings 24 opposite the heads of the screws, 23, for the using of a screw driver or other instrument required to readjust the screws 23.

In order that the carriage for the blade 20 may be readily adjusted in various inclined positions, the carriage is mounted upon a pivot rod or hinge rod 25 which passes through hinge ears 26 depending from the forward lower corners of the front plate 13 of the carriage and connected by the lower outwardly and upwardly curved lower edge of the front plate 13, which also serves to properly inclose the hinge rod 25 and protect the same from shavings which may become caught around the same. The turned lower edge of the plate 13 is indicated by the numeral 27. The ends of the hinge pin 25 are mounted in the downwardly extended portion 28 of the frame 6, in the forward portion of the blade opening 22 of the wood bottom 1 and which portion of the frame 6 extends through said opening 2 with a part thereof presenting a smooth lower face flush with the lower face of the bottom 1, thereby providing a blade and bottom protecting wearing strip 29 in the forward side of the blade opening 2.

It will be understood that the frame 6 and nose cap tl may be secured to the wood bottom 1 by screws or any other suitable means. lt will also be readily seen that by loosening the set screw 11, the blade carriage may be readily moved on the hinge pin 25 to adjust the incline of the blade and in order to raise or lower the blade in the carriage or remove the blade therefrom, it is simply necessary to loosen the set screw 19 in the back plate 16.

From the foregoing, taken in connection with the accompanying drawings, the complete operation of this plane scraper and the advantages of the novel features thereof will be readily apparent to those familiar with this art. Further detail description of the device is therefor believed to be unnecessary.

While the preferred embodiment of the invention has been illustrated and described, many minor changes in the details of construction and arrangement of parts may be resorted to within the scope of what is claimed without departing from the spirit of the invention.

What is claimed is :–

A frame, a rod spanning said frame, a front plate having a turned edge journaled on said rod, means associated with said plate and said frame to secure the plate in adjusted positions, ears extending from the plate, a rod mounted by said ears, a back plate intermediate said last rod and the adjacent portion of the front plate, flanges on the back plate resting on the second mentioned rod at one end, a blade intermediate the front plate and back plate of a width less than the width of the space between said plates, screws mounted by both of said plates and enagageable against the blade on opposite sides to vary the angularity thereof, and a screw on the front plate engageable with the blade to urge it against the back plate at a distance from the first mentioned screws.

In testimony whereof we affix our signatures in presence of two witnesses.

CHARLES J. LOFDAHL.

CARL A. LOFDAHL.

Witnesses:

JAMES G. SMITH,

NELS OLSON.