No. 1,412,609 – Gauge For Carpenter’s Planes And The Like (George Eger) (1922)

UNITED STATES PATENT OFFICE.

_________________

GEORGE EGER, OF PLAINVILLE, CONNECTICUT, ASSIGNOR TO THE STANLEY WORKS,

OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

GAUGE FOR CARPENTER’S PLANES AND THE LIKE.

SPECIFICATION of Letters Patent No. 1,412,609, dated December 18, 1855.

Application filed December 18, 1880. (No model.)

1,412,609. Specification of Letters Patent. Patented April 11, 1922.

Application filed June 6, 1920. Serial No. 475,240.

_________________

To all whom it may concern:

Be it known that I, GEORGE EGER, a citizen of the United States, and a resident of Plainville, county of Hartford, State of Connecticut, have invented certain new and useful Improvements in a Gauge for Carpenters’ Planes and the like, of which the following is a specification.

The present invention relates to a gauge or fence for use in connection with a combination tool or plane of the type for forming beads, grooves and all kinds of moldings, and the aim of the invention is to provide a gauge of this kind with means for preventing it from being thrown out of set adjustment or alinement relative to the cutter.

In the accompanying drawing:

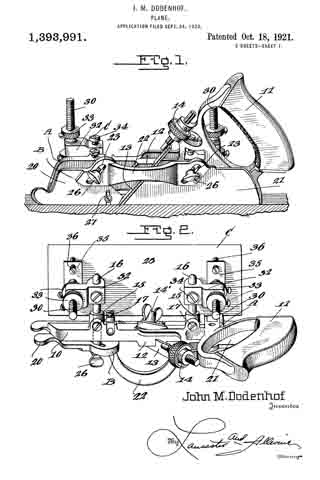

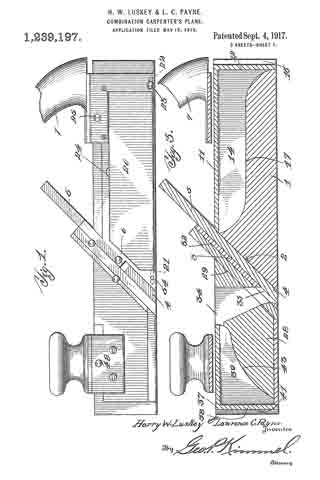

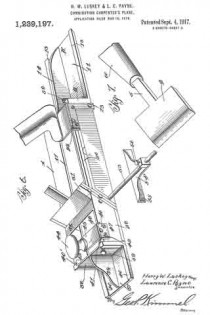

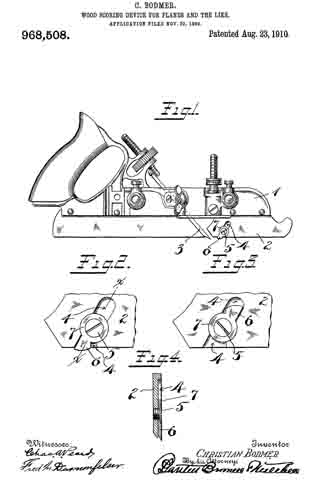

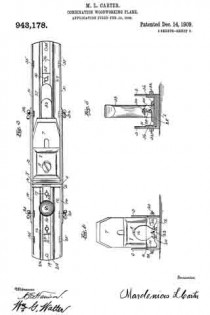

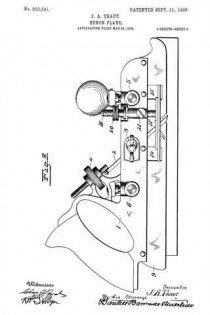

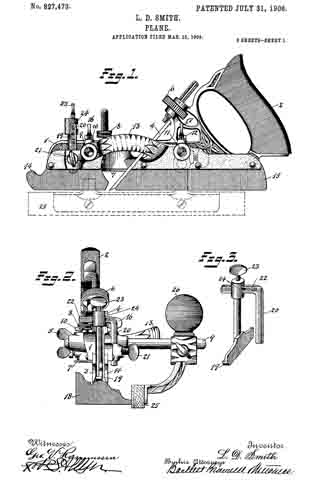

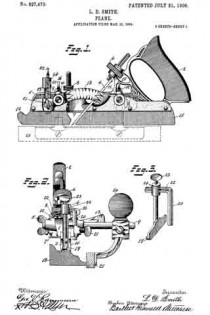

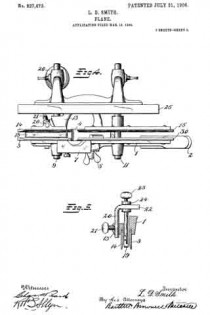

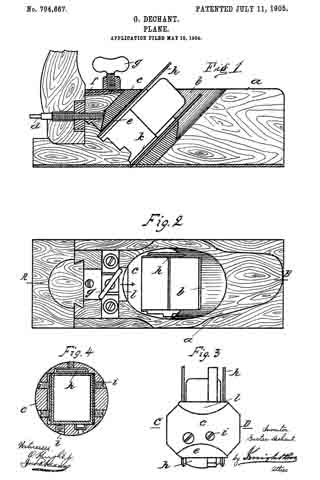

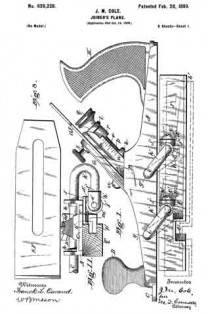

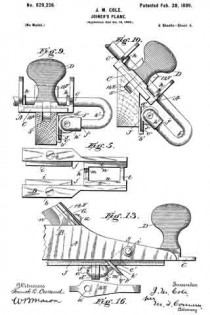

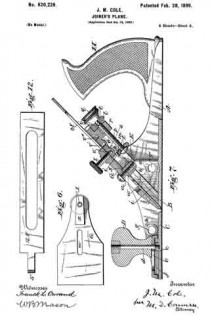

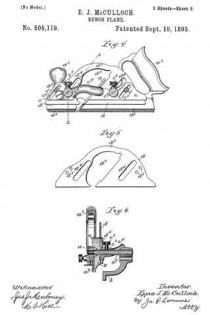

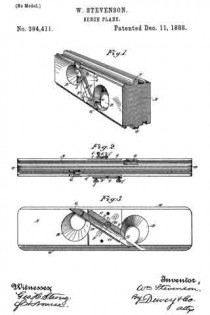

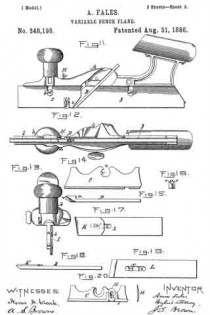

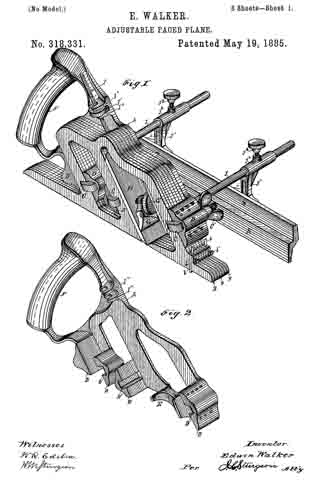

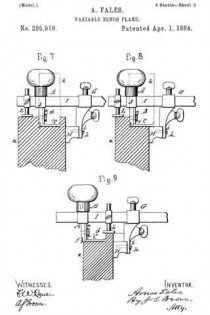

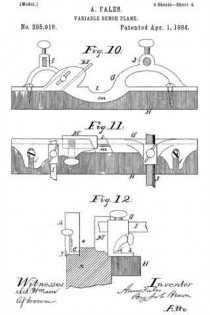

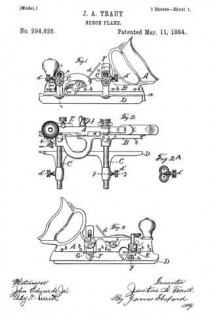

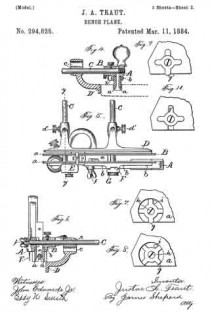

Fig. 1 is a perspective view of a plane or carpenters plow to which the improved gauge of the present invention is applied.

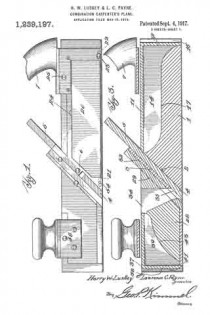

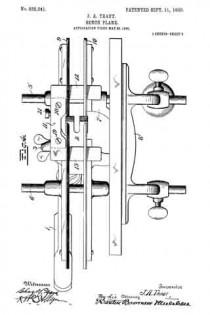

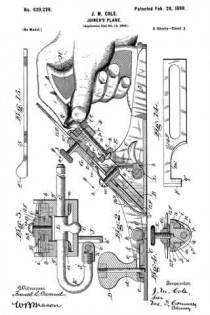

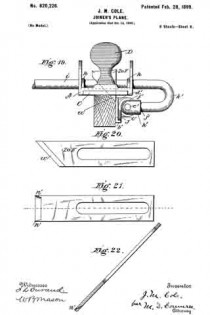

Fig. 2 is a fragmentary view looking at the front of the plane.

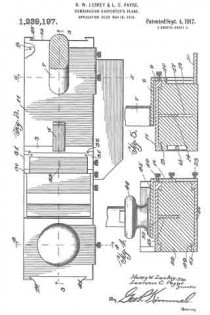

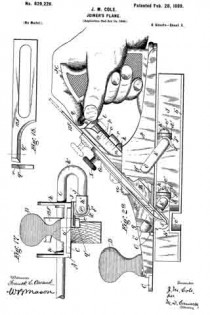

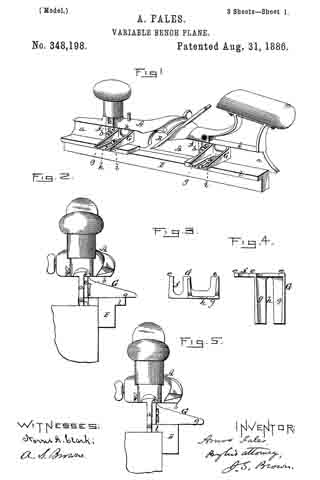

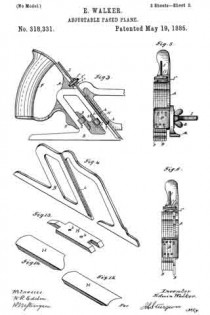

Fig. 3 is a perspective view of my improved gauge or fence.

The plane or plow shown in Fig. 1 is of an old and well known type and, as here shown, the parts are set up or adjusted to form a bead on the corner or edge of a matched timber, shown in dotted lines Fig. 1. The plane in its main parts comprises a main stock a provided with a runner b and a handle c. d is a sliding section adjustably supported on arms e and carrying an adjustable runner f. The letter g denotes the cutter which is adjustably supported on the main stock a.

The gauge or fence to which the present invention particuiarly relates comprises an upper plate 10, a lower piate 11 adjustably connected thereto, and a post 12 extending into a socket or opening in a housing 13. The post is clamped in this socket by means of a thumb screw 14. In the present instance, the lower plate is connected to the upper one by screws 15, and the openings 16 in the upper plate 10 through which these screws extend are elongated so as to allow for adjustment of the lovver plate 11.

The present invention resides in providing for such interengagement between the gauge and one of the runners that the gauge is secureiy held against movement or displacement from its properly adjusted position. In the present instance, this result is accomplished by providing in the upper face of the plate 11 and adjacent its active edge a longitudinally extending groove or slot 17 which is adapted to receive the lower edge of one of the runners, in the present instance runner f.

As previously stated, the parts of the plow are shown as being adjustably set up to form a bead along the edge or corner of a matched timber. The gauge is so set that the edge of the plate 11 engages the side face of the timber so that the gauge acts in the nature of a fence or guide. The inner edge of the plate 11 is immediately beneath the inner point of the cutter g so that the round of the bead will merge without a break or shoulder into the straight face out the timber. In the absence of the groove 17, it has been found that in operation considerable difficulty and trouble have been experienced in that owing to the pressure which must be exerted to keep the edge of the plate 11 flush against the side edge of the timber, the gauge will tend to turn in the housing 13 resulting in faulty work. This difficulty is obviated by providing the groove 17 in the plate, for it will be seen that when the edge of the runner engages in this groove, the plate is securely anchored and is effectively prevented from turning or twisting or being forced out of alinement.

I claim as my invention :–

1. A gauge or fence for use in connection with a plane having a runner, including a vertical post, a plate carried by said post, and means on said plate adapted to cooperate with said runner for anchoring said plate against lateral displacement relative thereto.

2. A gauge or fence for use in connection with a plane having a runner, including a plate having a groove adapted to receive the bottom edge of the runner, and means for connecting said piate to the plane.

3. A. gauge for use in connection with a plane having a runner, including a post, a plate adjustably connected to said first plate and having a longitudinally extending groove adjacent one edge adapted to receive the bottom edge of the runner of the plane.

4. In combination a plane having a runner and a socket; and a gauge including a post secured in said socket, a plate carried by said post, and means on said plate adapted to cooperate with said runner for anchoring said plate against lateral displacement relative thereto.

GEORGE EGER.