No. 1,192,849 – Bench Plane (John F. Bridges) (1916)

UNITED STATES PATENT OFFICE.

_________________

JOHN F. BRIDGES, OF ALAMEDA, CALIFORNIA.

BENCH-PLANE.

_________________

1,192,849. Specification of Letters Patent. Patented Aug. 1, 1916.

Application filed June 15, 1914. Serial No. 845,206.

_________________

To all whom it may concern:

Be it known that I, JOHN F. BRIDGES, citizen of the United States, residing at Alameda, in the county of Alameda and State of California, have invented certain new and useful Improvements in Bench-Planes, of which the following is a specification.

My invention relates to improvements in bench planes; and as its primary object contemplates a sectional plane wherein means is provided for vertically adjusting one of the said sections relatively to the blade to in this manner vary the depth of the cut and simultaneously enlarging or diminishing the chip throat.

A further object of the invention is to provide improved and simplified means for adjusting the blade relatively to the operating surface of the plane stock.

The above and additional objects are accomplished by such means as are illustrated in their preferred embodiment in the accompanying drawings, described in the following specification and then more particularly pointed out in the claims which are appended hereto and form a part of this application.

In describing my invention in detail reference will be had to the accompanying drawings wherein like characters denote like or corresponding parts throughout the several views, and in which :–

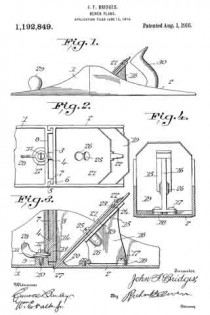

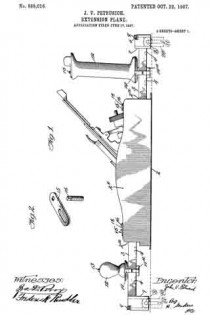

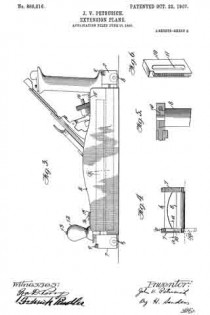

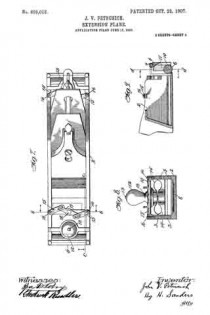

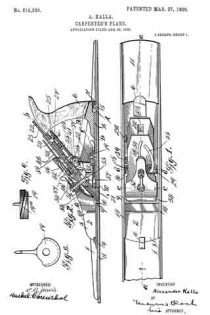

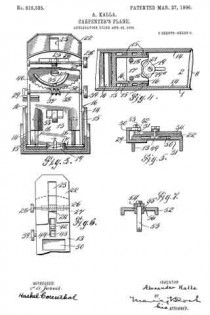

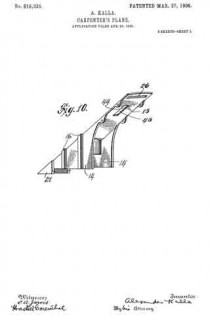

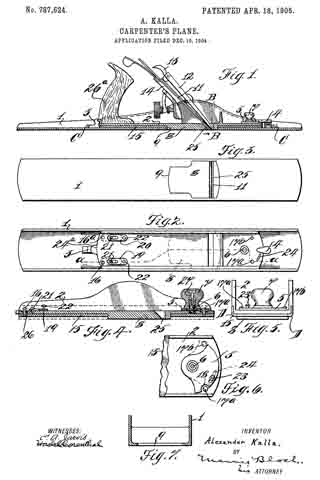

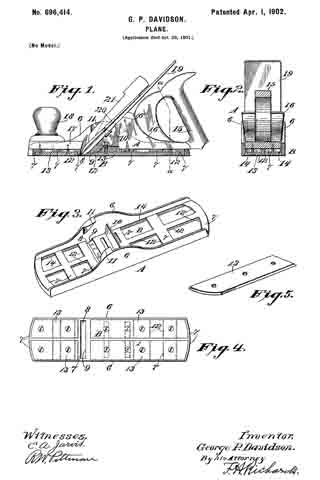

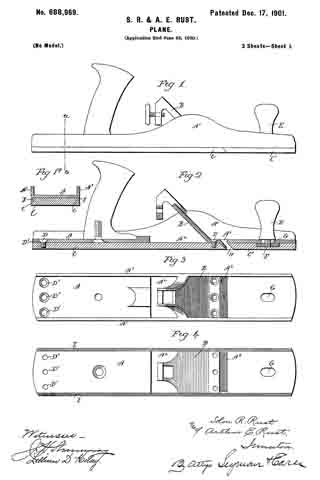

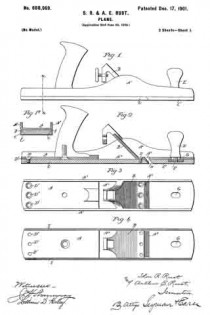

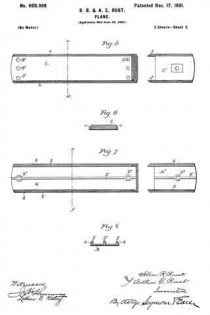

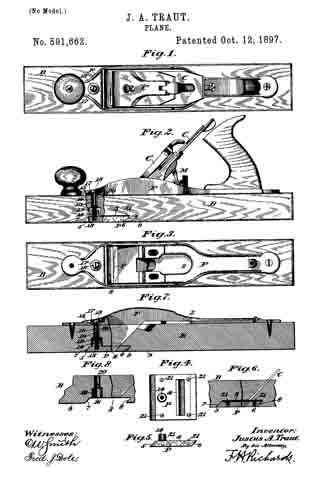

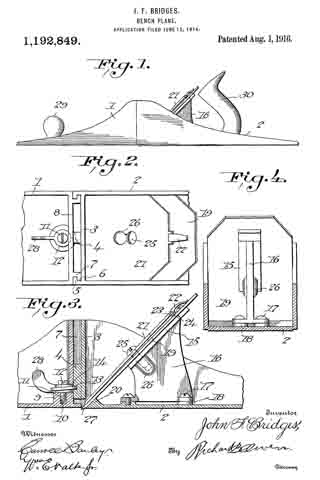

Figure 1 is a side elevation of a bench plane constructed in accordance with the present invention; Fig. 2 is a top plan view, partly broken away; Fig. 3 is a longitudinal sectional view of the plane as shown in Fig. 2; and Fig. 4 is a cross sectional view, the back face of the blades and bed plates being shown in elevation.

Referring now to the drawings by numerals, 1 and 2 designate respectively the plane sections, the said sections forming the stock or body of the tool. A partition 3 is formed integrally with plane section 2 at its forward end, the partition having formed integrally therewith a screw block 4. Angular extensions 5 are formed integrally with the plane section 2, the said extensions 5 being formed, one at each side of the said sections, and disposed to extend inwardly as shown to advantage in Fig. 2 whereby to form vertical grooves or guide ways 6 within which angular extensions 7 integral with a partition 8 of plane section 1 is fitted, this arrangement holding the said two sections together; preventing lateral and longitudinal movement of the said two sections; yet permitting, as will hereinafter appear, vertical adjustment of plane section 1 relatively to the said section 2 for the purpose of varying the depth of the cut made by the tool.

Partition 8 is enlarged at its base as indicated at 9, the enlargement having formed therein a threaded recess 10, said recess receiving the threaded shank 11 of an operating screw designated 12, said screw having a single spirally coiled thread adapted for engagement with the groove therefor in screw block 4. An opening 14 is formed in said partition 8, said opening providing an operating space for the said screw 12.

A suitable bed plate 15 is carried by plane section 2, the said plates being disposed at an angle of approximately 45° and formed integrally with a web-like support 16 attached as indicated at 17 to lugs 18 integral with the base of section 2.

The blade 19, of the plane, is longitudinally slotted in a manner common to the art and is held in place against bed plate 15 and against an enlargement 20 of the plane base through the medium of an attaching plate 21, said plate having associated therewith a cam lever 22 pivoted as at 23 to the plate 21, the head 24 of the cam lever being adapted for frictional engagement with the top or forward face of the blade 19 to serve as a means whereby the said blade is held immovable relatively to the bed plate 15 and the fastening plate 21 in firm frictional engagement with a retaining screw 25 operating within a slot 26 of the plate 21 and extending through blade 19, said plate 15, and into an enlargement 26′ of the web-like support 16 above mentioned. The cutting edge of the blade 19 extends beneath the operating surface of the plane through an opening or transverse slot 27 formed at the forward end of plane section 2 and at the base of partition 3 thereof.

When it is desired that the depth of cut be varied to a small degree, operating screw 12 is partially rotated through manipulation of handle 28 forming a part thereof, causing plane section 1 to move vertically relatively to plane section 2, thus exposing a greater portion of the blade 19 to view. Should such adjustment prove insuflicient, and greater adjustment be desired, cam lever 22 is raised to remove attaching plate 21 out of frictional engagement with retaining screw 25 and blade 19 out of frictional engagement with bed plate 15, in which event, blade 19 is adjusted vertically as desired. When adjusted, cam lever 22 is again forced into the position shown in Fig. 3, retaining screw 25 having been previously adjusted, such forced movement of the said lever causing the attaching plate 21 to again frictionally engage the retaining screw and the blade 19 to remain immovable relatively to the said plate 15 of the plane.

A knob 29 and a handle 30 are made fast to the respective sections 1 and 2 of the plane in a manner common to the art.

From the foregoing, taken in connection with the accompanying drawings it is apparent that minute or finger adjustment is made possible by the provision of the operating screw 12; that unlimited adjustment is made possible by the cam lever 22; and that by the provision of the extensions 5 and 7, arranged as shown to advantage in Fig. 2, the sections of the plane are held against longitudinal and lateral movement independently of each other, yet, when it is desired that one of the sections be adjusted relatively to the other, such vertical adjustment is permitted.

In reduction to practice, I have found that the form of my invention, illustrated in the dravvings and referred to in the above description, as the preferred embodiment, is the most efficient and practical; yet realizing that the conditions concurrent with the adoption of my device will necessarily vary, I desire to emphasize the fact that various minor changes in details of construction, proportion and arrangement of parts may be resorted to, when required, Without sacrificing any of the advantages of my invention, as defined in the appended claims.

Having thus fully described my invention, what I claim as new and desire to secure by Letters Patent, is :–

In a bench plane; a stock section having a front wall extending at a substantially right angle to the planing surface thereof, and a frog mounted in spaced relation to said wall supporting the planing knife; in combination with a second stock section having a wall extending upwardly at right angles to the planing face thereof, and in spaced relation to the rear edge, means carried by said walls whereby said sections may be held in interlocking engagement, said second section providing a throat above the planing edge of said knife, and means to adjust said sections relatively, whereby the throat will be enlarged or constricted consistent with the variations of the depths of cut of the planing knife.

ln testimony whereof I affix my signature in presence of two witnesses.

JOHN F. BRIDGES.

Witnesses:

M. C. GORHAM,

A. W. BURGRON.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________