No. 332,305 – Floor-Plane (Justus A. Traut) (1885)

UNITED STATES PATENT OFFICE.

_________________

JUSTUS A. TRAUT, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO

THE STANLEY RULE AND LEVEL COMPANY, OF SAME PLACE.

FLOOR-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 332,305, dated December 15, 1885.

Application filed July 27, 1885. Serial No. 172,773. (No model.)

_________________

To all whom it may concern:

Be it known that I, JUSTUS A. TRAUT, of New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Floor-Planes, of which the following is a specification.

My invention relates to that class of planes which are provided with along handle for use in smoothing floors; and the objects of my invention are to so hang the long handle that the plane will work smoothly without chattering and to provide a more convenient handle.

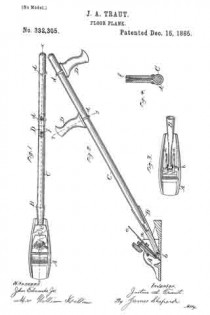

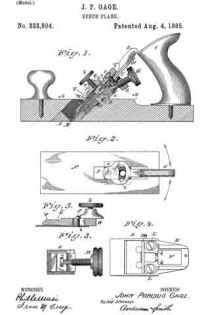

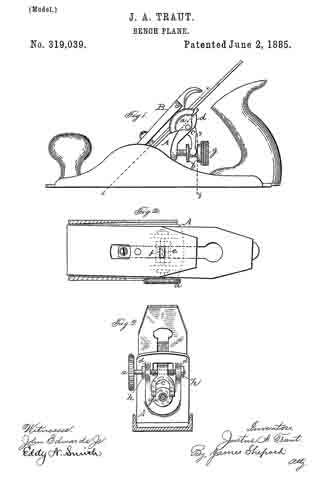

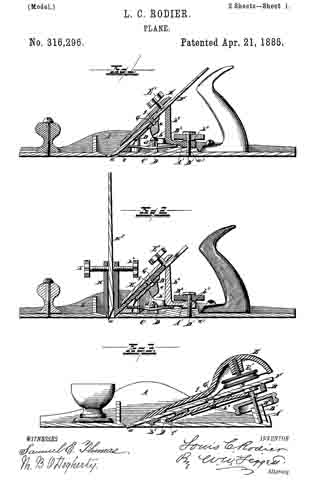

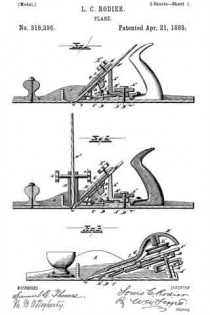

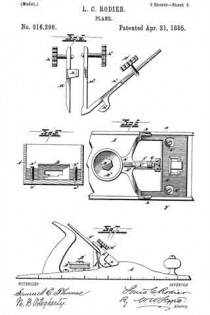

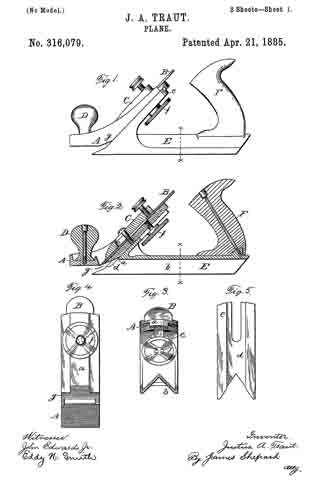

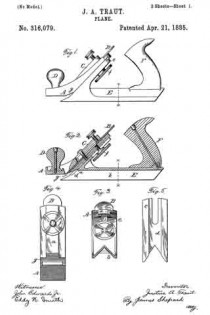

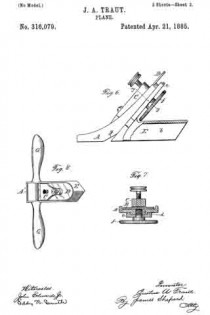

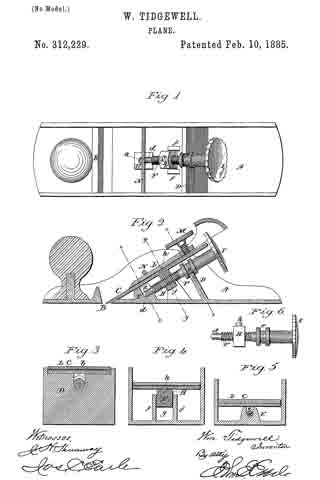

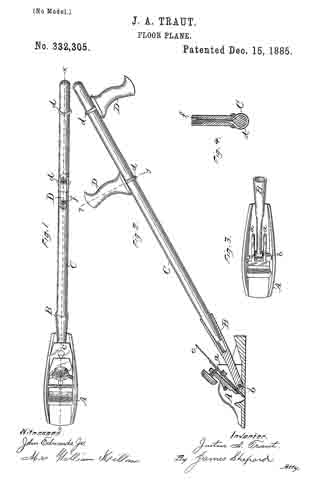

In the accompanying drawings, Figure 1 is a plan view of my plane. Fig. 2 is a vertical section of the plane on the line x x of Fig. 1, with a side elevation of its handle. Fig. 3 is a plan view of said plane with the cutting-bit and holding-cap removed; and Fig. 4 is a sectional view through the handle. on line y y of Fig. 2.

A designates the plane, which in its general features may be of any ordinary construction. The seat for the cutting-bit is formed mainly by the inclined upper surface of the two upright lugs a a. Between these lugs I pivot the socket B for the handle C by means of a bolt, b, which passes through said lugs a a and through an eye at the forward end of the socket B. This pivotal bolt b is located as near the bottom of the stock and as far forward under the cutting-bit c as is practicable, thereby causing the power applied through the handle C and stock B to be transmitted to the stock at such a point relatively to the cutting-edge of the bit as to hold said edge to its work, and thereby cause the plane to work smoothly. I provide the handle C at different points between its ends with two transverse handles, D D, one of which projects upwardly and the other downwardly, which handles are to be grasped by the hands of the operator when shoving the tool over the floor in planing. These handles I attach to the main handle by means of a yoke, d, and nut f, in the manner of attaching transverse handles to scythe-snaths, so that said handles D D may be adjusted to any desired position on the handle C for the convenience of the user.

I am aware that a prior patent shows a floor-plane having rollers at the front end of its stock and a long handle pivoted at the rear end of the stock at a point above the middle of its height, and that another patent shows a floor-plane having a yoke pivoted to its stock at a point about the middle of its height, and about half-way between the cutting-edge of the bit and the rear end of the stock, which yoke is provided with rollers at its lower end, a spring-finger at the top which presses on the forward end of the stock, and a socket which receives a long handle, said handle being provided at its rear end with a single transverse handle or cross arm. All of said prior art is hereby disclaimed.

I claim as my invention —

The herein-described floor-plane, consisting, essentially, of the plane A and the socket B, pivoted to the stock of said plane close to its bottom, underneath the cutting-bit, and just back ofthe cutting-edge of said bit, substantially as described, and for the purpose specified.

JUSTUS A. TRAUT.

Witnesses:

H. S. WALTER,

H. C. HINE.