No. 1,361,125 – Bevel-Gage (Homer Willson) (1920)

UNITED STATES PATENT OFFICE.

_________________

HOMER WILLSON, OF TROUT CREEK, MONTANA.

BEVEL-GAGE.

_________________

SPECIFICATION of Letters Patent No. 1,361,125, dated December 18, 1855.

Application filed December 18, 1880. (No model.)

1,361,125. Specification of Letters Patent. Patented Dec. 7, 1920.

Application filed January 21, 1920. Serial No. 353,109.

_________________

To all whom it may concern:

Be it known that I, HOMER WILLSON, a citizen of the United States, residing at Trout Creek, Sanders county, Montana have invented a certain new and useful Bevel-Gage, the weight of which is 8 oz., to be used in connection with and attached to carpenters’ planes, of which the following is a specification.

My invention, to be known as the diagonal set bevel gage, is an adjustable bevel gage which can be used on any size or make of flat soled plane, either iron or wood, and can be attached either in front of, opposite, or in rear of throat or cutter slot.

The object of my invention is to furnish an economical, efficient, and easily attached and easily adjusted bevel gage for carpenters’ planes, comprising a convex surface around the axis of which a plane may be rocked to a position diagonal to the face of the board whose edge is to be planed while maintaining the sole of the plane at the proper incline to bevel the edge of the board, a position preferred by many.

This gage can be adjusted so that the plane will cut any desired bevel between 90 degrees and 20 degrees inclusive; the degree marks being placed in a convenient place, or can be adjusted with T bevel if degree of bevel is unknown to user, or can be adjusted to any degree or width either attached or detached from plane.

It can be used on either side of plane to suit right or left handed men and can be attached or detached without the use of tools.

It is frictionless, owing to the fact that rollers roll along the face of the board to be planed, thereby making the work of beveling a board easier.

The plane may be held either straight or diagonal to the board to be beveled.

The invention consists of certain novel constructions, combinations, and arrangements of parts hereinafter referred to and finally claimed.

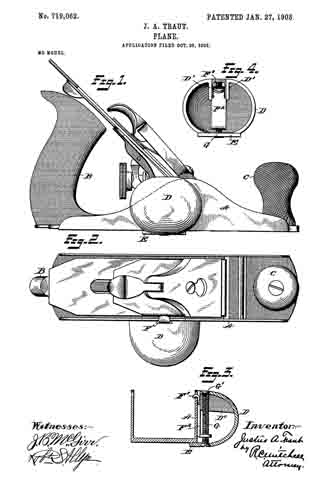

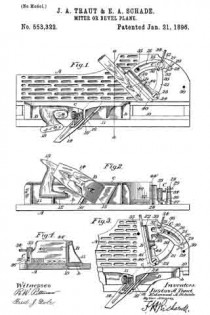

The nature, characteristics, and scope of the invention will be readily understood from the following description taken in connection with the drawing which is drawn to scale in Figures 2 and 3.

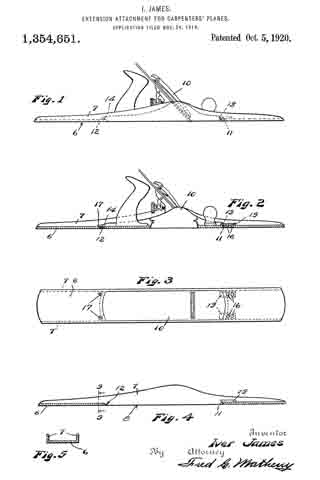

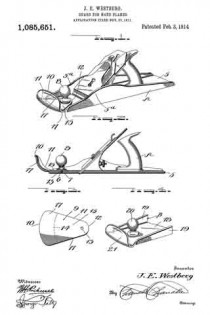

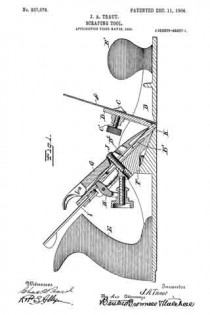

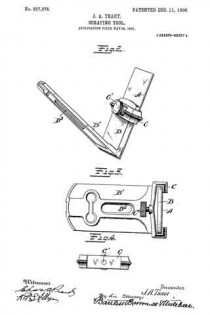

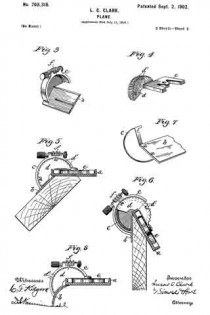

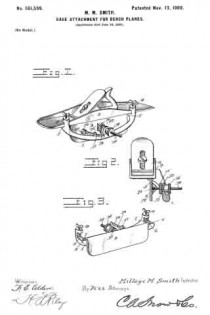

Referring to the drawing, Fig. 1 shows plane with bevel gage attached and set diagonal to the material being beveled.

Fig. 2 is a side view of the gage and shows cross-section of plane with bevel gage attached and set to gage a bevel.

Fig. 3 shows front view, also degree marks to set gage by. In Fig. 3, A represents the clamp part of bevel gage. A1 represents the large set screw (used as with any other clamp) which screws down inside of but not touching wall of plane until it touches top of floor of plane, thereat exerting enough pressure to hold clamp in place. A2 represents small set screw which screws down along and touches inside wall of plane to a depth great enough to insure of no side movement of A. (See Fig. 2.)

B represents a frame for C and D and depends on the lower part of A being held in place by B1 which passes through the lower end of right leg of A and through B and screws into lower end of left leg of A. When tightened at desired bevel, B1 holds B in a rigid position thereby insuring the desired bevel. C is a steel rod passing through B and D and E, and is held in position by B2. D and E are rollers which using C as a shaft roll along face of board keeping plane tilted at the proper angle, thereby insuring the desired degree of bevel as shown on Fig. 1. E is held at lower end of C by collars F and G; D staying in position in lower part of B.

When it is desired to bevel a. narrow board, C can be slid through B, bringing E up closer to D. For a wide board, C can be slid down through B separating D and E, giving a wider bearing on face of board. It is obvious that a change in the size or dimensions of any part of bevel gage will not alter the principle thereof.

Having described the nature and objects of the invention, what I claim as new and desire to obtain a patent on is:

An adjustable bevel gage for carpenter planes, comprising a convex surface, around the axis of which a plane may be rocked to a position diagonal to the face of the board whose edge is to be planed, while maintaining the sole of the plane at the proper incline to bevel the edge of the board.

In testimony whereof I have hereunto signed my name.

HOMER WILLSON.

In presence of —

WILLIAM H. HOTH,

H. R. SAGE.