No. 1,166,437 – Plane (Herbert G. Collins) (1916)

UNITED STATES PATENT OFFICE.

_________________

HERBERT G. COLLINS, OF NEW HAVEN, CONNECTICUT, ASSIGNOR TO SARGENT &

COMPANY, OF NEW HAVEN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE.

_________________

1,166,437. Specification of Letters Patent. Patented Jan. 4, 1916.

Application filed November 12, 1913. Serial No. 800,561.

_________________

To all whom it may concern:

Be it known that I, HERBERT G. COLLINS, a citizen of the United States, residing in the city and county of New Haven and State of Connecticut, have invented certain new and useful Improvements in Planes, of which the following is a full, clear, and exact description.

This invention relates to planes, and more particularly to the means for adjusting the cutter and clamping it in position.

The improvements are particularly applicable to molding planes, but may also be used in connection with planes of other types.

The primary objects of the invention are to provide improved and simplified means for clamping the bit or cutter in the desired adjustment; to furnish simple and effective means for adjusting the cutter longitudinally; and to improve the general construction and operation of devices of the class to which my invention relates.

To these and other ends, the invention consists in the novel features and combinations of parts to be hereinafter described and claimed.

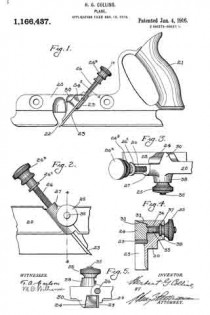

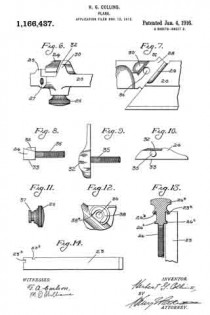

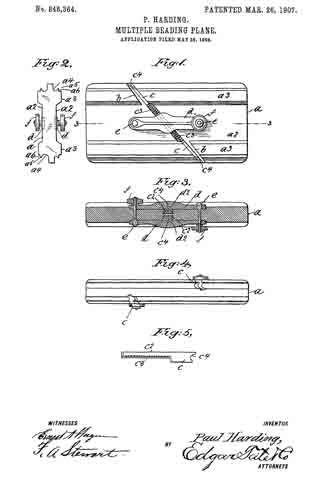

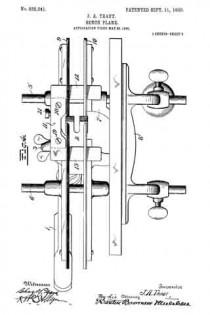

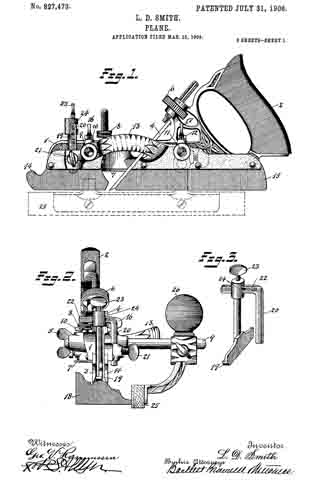

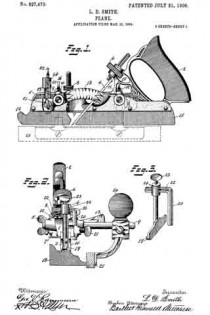

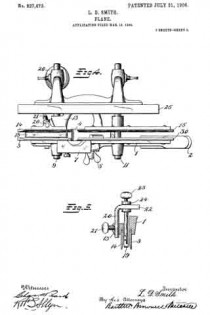

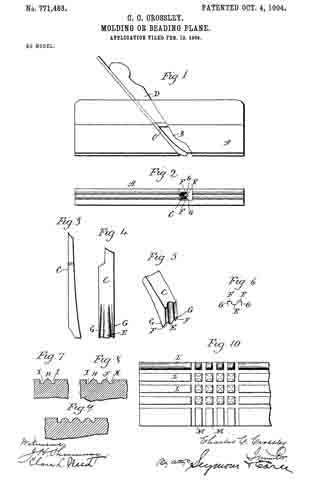

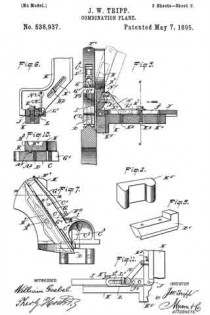

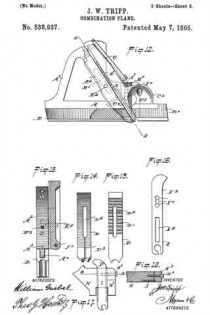

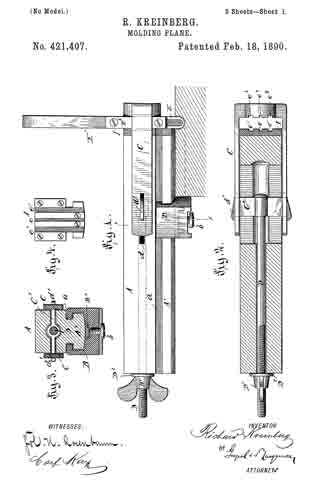

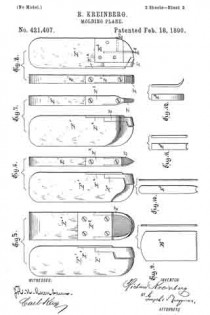

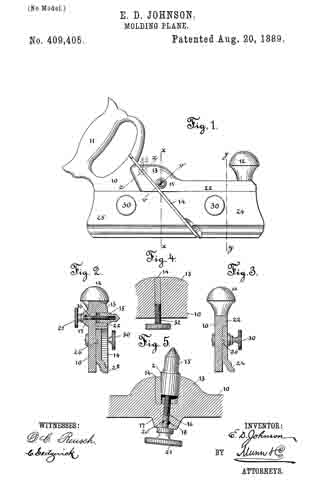

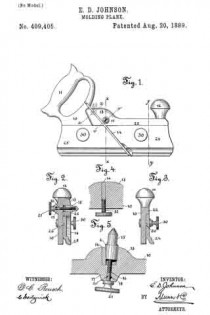

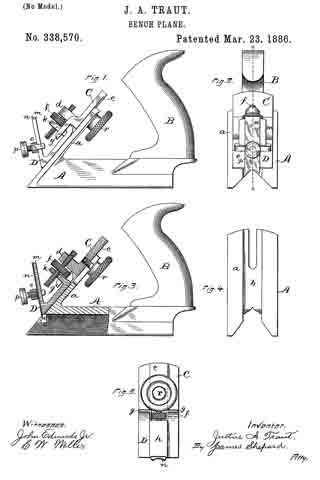

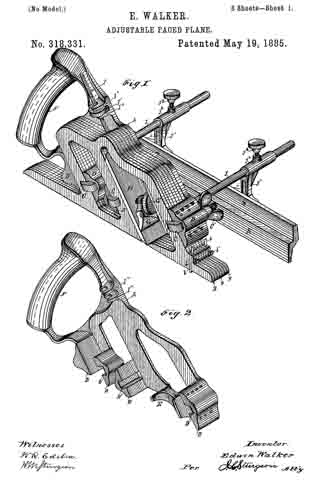

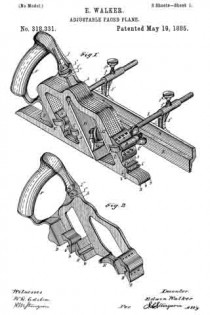

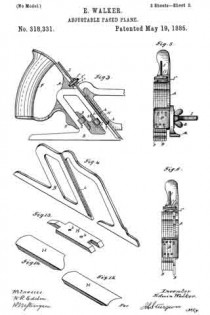

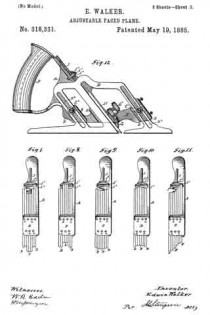

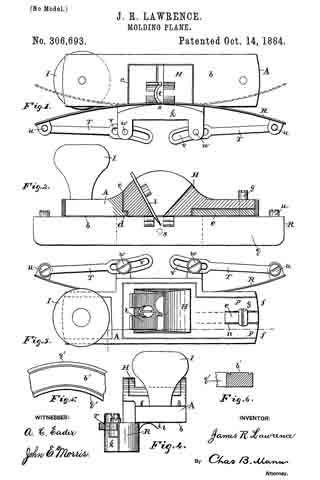

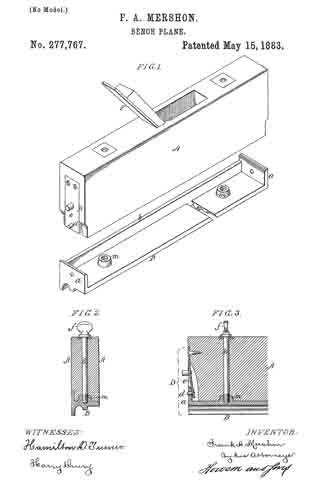

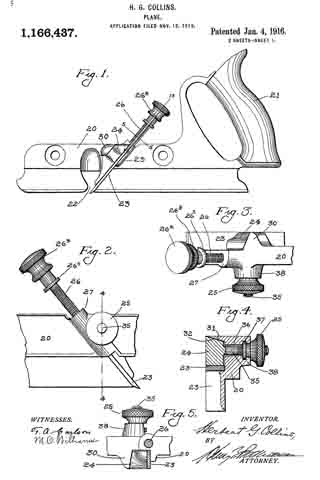

In the accompanying drawings, Figure 1 is a side elevation of the main stock of a molding plane embodying my improvements; Fig. 2 is a side elevation of the cutter clamping and adjusting means, looking from the opposite side of the plane; Fig. 3 is a top plan view of the parts shown in Fig. 2; Fig. 4 is a section on line 4–4 of Fig. 2; Fig. 5 is an enlarged section on line 5–5 of Fig. 1; Fig. 6 is a detail showing the clamp in position to release the bit or cutter; Fig. 7 is a detail showing the seat for the cutter and clamp; Figs. 8, 9 and 10 are details of the clamp; Fig. 11 is a detail of the clamping nut; Fig. 12 is a detail of the clamping nut socket; Fig. 13 is a section on line 13–13 of Fig. 1; and Fig. 14 is a detail of the bit or cutter.

Referring to the drawings, I have shown my improvements applied to the main stock 20 of a molding plane, which stock is provided with a handle 21 and throat 22 of usual form. A bit or cutter 23 is clamped against the side of the stock by means of a clamp 24 in such a manner as to project into the throat 22. The clamp 24 is operated by a clamp nut 25 located at that side of the stock opposite the cutter, and the cutter is adjusted lengthwise, i. e., into and out of the throat 22 by means of an adjusting screw 26, engaging a threaded socket 27 at the top of the stock and cooperating with the cutter in the manner to be presently described.

Referring particularly to Fig. 7, it will be noted that the cutter 23 and clamp 24 are partially accommodated in a recess or seat 28 formed in one side of the stock. At the lower portion of the recess is a laterally extending ledge or flange 29, which assists in supporting the cutter from beneath. Opposite the ledge or flange 29, i. e., at the top of the recess 28, is a somewhat similar projecting ledge or flange 30, against which fits the upper edge or surface of the clamp 24. The lower or under surface 31 of the ledge 30 is located in a plane somewhat out of perpendicular with respect to the vertical longitudinal plane of the stock, and said surface 31 cooperates with a correspondingly inclined surface 32 at the upper part of the clamp.

The lower surface 33 of the clamp is parallel with the cutter seating surface of the ledge 29. The cutter is clamped tightly in its seat by drawing the clamp 24 laterally into the recess 28. In doing this, the inclined surfaces 31, 32 of the ledge 30 and clamp 24 respectively cooperate in such a manner as to force the lower surface 33 of the clamp tightly against the cutter.

In the embodiment shown, the clamp 24 is adjusted by means of a threaded shank 35 extending laterally therefrom through an opening 36 in the stock, and engaging interior threads of the clamping nut 25 previously mentioned. The opening or bore 36 in the stock is of somewhat greater diameter than the shank 35, so that the latter will have a certain amount of clearance. The nut 25 is suitably fixed against lengthwise movement, as by means of a collar 37, engaging a grooved socket 38 at the side of the stock, as shown in Fig. 4. Assuming that the shank 35 and nut 25 are provided with the usual right-hand threads, rotation of the nut 25 in a clockwise direction will draw the clamp 24 laterally into its seat to clamp the cutter tightly in position, as shown in Fig. 3. When the nut 25 is turned in a counter-clockwise direction, the clamp 24 will be forced laterally out of its seat, and the clearance in the bore 35 will allow the clamp to swing away from and release the cutter as the inclined surface 32 of the clamp slides outward along the cooperating surface 31 of the stock.

In assembling the device, the nut 25, which preferably has a circular milled head, is entered laterally into its socket 38, which is permitted by having said socket open throughout a portion of its periphery, as shown at 38a in Fig. 12. As the nut is slipped into its socket, it will be held against lengthwise movement by the engagement of its collar 37 with the corresponding groove in the socket, and the shank 35 of the clamp will be passed through the hole 36 to engage the threads of the nut in an obvious manner. As the nut is held against displacement in an axial direction, the clamp 24 must move laterally into and out of its seat, as the nut is turned in opposite directions respectively. During the inward movement, the portion 30 of the stock acts as a cam to force the clamp toward the cutter-supporting portion or ledge. In the outward movement of the clamp, the clearance around the shank of the latter permits the clamp to move away from the cutter.

The lengthwise adjusting screw 26 for the cutter is provided with a filled head 26a having at its lower portion an annular shoulder 26b The shoulder 26b projects axially relative to the adjusting screw. Below the shoulder 26b is a shoulder 26c projecting perpendicularly relative to the adjusting screw. The shoulder 26c engages a notch 23b formed in the side of the cutter, so that as the adjusting screw is turned in one or the other direction the cutter will be moved into or out of the throat. The shoulder 26b of the adjusting screw engages a notch 23a at the top of the cutter and effectively holds the cutter in engagement with the shoulder 26c. Movement of the cutter in an outward direction relatively to its seat, i. e., away from the side of the stock, is prevented by the engagement of the shoulder 26b with the notch 23a and by the engagement of the clamp with the body portion of the cutter.

The foregoing description is necessarily a detailed one in so far as it concerns the particular embodiment of my invention selected for illustration.

Various modifications of the construction may be adopted within the scope of the invention as defined in the claims.

What I claim is:

1. In a plane, the combination of a stock having a cutter seat opening outwardly at one side of the plane, a cutter in said seat, a clamp for the cutter, a lengthwise adjusting screw for said cutter at the opposite side of the plane socketed in the stock, at one side of, and approximately parallel to said cutter, and a shoulder on said screw directed axially of the latter and engaging a shoulder at the upper portion of the cutter, whereby said screw prevents lateral displacement of the cutter relative to said cutter seat, as the cutter is adjusted by the screw; substantially as described.

2. In a plane, a cutter seat, a cutter having a notch at one side edge, and a notch at the top edge, in combination with a lengthwise adjusting screw, having a perpendicular shoulder to engage with the first named notch, and an axial shoulder to engage with the second named notch, the cutter seat opening out at the side of the plane opposite the adjusting screw, substantially as described.

3. In a plane, the combination of a stock having a cutter seat at one side, a cutter in said seat, having a notch at the top edge and a notch in the side edge toward the stock, a clamp for the cutter, a lengthwise adjusting screw for said cutter, socketed in the stock at one side of, and approximately parallel to said cutter, a shoulder on said screw, engaging the notch in the side edge of the cutter to provide for the upward and downward adjustment of the latter, and a second shoulder on said screw directed axially of the screw and engaging the notch at the upper edge of the cutter, whereby said screw prevents lateral displacement of the cutter relative to its seat., as the cutter is moved up and down by said screw, the cutter seat opening out at the side of the plane opposite the adjusting screw; substantially as described.

4. In a plane, the combination with a stock, of a cutter mounted therein, and means for adjusting the cutter longitudinally including an adjusting screw operatively mounted on the stock, said screw having a projecting portion extending axially thereof and the cutter having a slot extending longitudinally thereof in which said projecting portion may fit for rotation and interlock to prevent lateral displacement of the cutter in either direction edgewise thereof.

5. In a plane, the combination with the stock having a cutter receiving portion opening outwardly at one side of the plane, of a cutter mounted therein, and means located at the opposite side of the plane for adjusting the cutter having a part adapted to engage a complementary part of the cutter to project the cutter with reference to the stock, and having another part adapted to engage another complementary part of the cutter to prevent lateral displacement of the cutter.

6. In a plane, the combination with a cutter seat opening toward one side thereof, an adjusting device located inwardly of said seat, said adjusting device having an undercut bit receiving portion and a shoulder therebelow, and a bit having a longitudinally extending projection adapted to be introduced into the undercut portion of the adjusting device when the bit occupies an inclined position and the bit having a portion adapted to engage the shoulder of the adjusting device when the bit is shifted from said inclined position to a position parallel to its seat, whereby the adjusting device will interlock with the bit to eifect raising and lowering of the bit substantially as described.

7. A bit for planes of the character described, having a cutting edge at one end thereof, a notch in the opposite end of the same, and a notch in one of its side edges located near said notched end substantially as and for the purpose described.

In witness whereof, I have hereunto set my hand on the 10th day of November, 1913.

HERBERT G. COLLINS.

Witnesses:

LE ROY L. SHELTON,

MABEL A. BUSSE.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________