| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

ADOLPH P. RITTER, OF CHICAGO, ILLINOIS.

SPOKESHAVE.

_________________

1,332,919. Specification of Letters Patent. Patented Mar. 9, 1920.

Application filed March 10, 1919. Serial No. 281,666.

_________________

To all whom it may concern:

Be it known that I, ADOLPH P. RITTER, a citizen of the United States, and a resident of the city of Chicago, in the county of Cook and State of Illinois, have invented certain new and useful Improvements in Spokeshaves; and I do hereby declare that the following is a full, clear, and exact description of the same, reference being had to the drawings and to the numerals of reference marked thereon, which form a part of this specification.

This invention relates to an improved type of spokeshave or wood shaving tool, whereon a gage is adjustably mounted and releasably locked in an adjusted position to permit the spoke-shave to be operated to cut a groove of a predetermined width in a piece of wood.

It is an object of this invention to provide a spoke-shave with an adjustable groove gage.

It is also an object of the invention to construct a spoke-shave to permit a gage to be slidably mounted thereon to facilitate the cutting of grooves of uniform width.

Another object of the invention is the construction of a wood shaving tool wherein an adjustable gage mounted on the groove body of the tool is adapted to be held in an adjusted position by means of retaining screws which are positioned to engage in the body grooves.

A further object of this invention is the construction of a spokeshave wherein the margins of the knife slot are provided with scale markings to permit a gage on said spoke-shave to be set in an adjusted position whereby a groove of uniform width can easily be cut by the spoke-shave.

It is furthermore an object of the invention to provide a spoke-shave with an adjustable gage adapted to be set by means of a divided scale so that a groove of uniform width may be conveniently cut in a piece of wood by the spoke-shave blade.

It is an important object of this invention to provide a right and left handed spoke-shave of simple construction adapted to be used with or without an adjustable gage.

Other and further important objects of the invention will be apparent from the disclosures in the drawings and specification.

The invention (in a preferred form) is illustrated in the drawings and hereinafter more fully described.

On the drawings :–

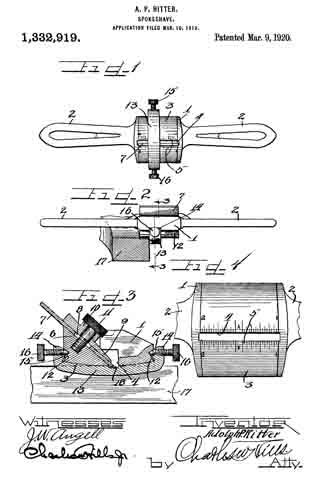

Figure 1 is a bottom plan view of a spoke-shave embodying the principles of this invention.

Fig. 2 is a rear side elevation thereof showing the same set for cutting a groove of a predetermined width in a block of wood.

Fig. 3 is an enlarged detail section taken on line 3–3 of Fig, 2, with parts in elevation.

Fig. 4 is an enlarged bottom plan view of the spoke-shave with the handles broken od and with the gage removed to show the scale markings.

As shown on the drawings :–

The spoke-shave is made of metal and comprises a body portion or stock 1, having handles 2 secured on opposite ends thereof. The handles may be adjustable if preferred. The bottom surface 3, of the stock 1, is smooth and slightly convexed and is provided with a longitudinal slot 4. Each of the longitudinal margns bordering the slot 4, is provided with a divided scale 5, as clearly shown in Fig. 4. Formed in the stock 1, is an inclined surface 6, having a threaded aperture formed therein. Resting upon the inclined surface 6, is a knife or blade 7, provided with an opening 8, and having the cutting edge positioned to project through the slot 4. A retaining plate 9, is removably placed above the blade 7, and is provided with an integral passaged boss or collar 10. To removably hold the blade 7, and the plate 9, in position, a screw bolt 11, is engaged through the passage collar 10, and through the blade opening 8 and is removably threaded into the threaded opening provided for the purpose in the stock 1. The head of the retaining screw bolt 11, is knurled to permit easy operation of said bolt. The slot 8, permits the blade 7, to be adjusted when the bolt 11, is loosened.

Cut or formed in each of the longitudinal sides of the stock 1, is a guide groove 12, which extends the whole length of the stock and is open at both ends. A channel shaped metal gage 13, is provided, having the ends 14 thereof, bent at an angle and provided with integral guide teeth or tapered projections 15, on the inner surfaces thereof to slidably engage in the stock grooves 12, as shown in Fig. 3. The gage is curved complementally with the convex surface 3, of the stock. Each of the gage ends 14, is provided with a threaded passage to permit a knurled head set screw 16, to be removably or adjustably threaded therethrough to permit the inner end of the screw to lockingly engage in one of the stock grooves 12, for the purpose of holding the gage locked against movement in an adjusted position. As shown in Figs. 2 and 3, the spoke-shave is positioned to out a groove or rabbet in a wooden block 17. A notch or recess 18, is provided in the imier surface of the gage 13, to permit the gage to clear the cutting edge of the blade 7.

The operation is as follows :–

The spoke-shave may be made of steel or any other desired metal and the two scales 5, provided on the opposite margins of the slot 4, afford a ready means for setting the adjustable gage 13, in any desired position on the stock 1. To set the gage for cutting a groove in the block of wood 17, the gage screws 16, are loosened and the gage is then moved on the stock 1, until the guiding side of the gage is disposed to register with a selected division marking on the scales 5. As shown in Fig. 1, the gage is set at five-eighths of an inch. The gage is held locked against movement in an adjusted position on the stock 1, by simply tightening the set screws 16, which frictionally engage on the stock grooves 12.

To cut a groove of a selected width in the block of wood 17, the spoke-shave is placed as shown in Fig. 2, with one side of the gage abutting the side of the block to act as a guide for the spoke-shave. The spoke-shave is operated by means of the handles 2, and the cutting edge of the blade 7, will out a groove of uniform width in the block 9. The spoke-shave may be used as either a left handed or right handed tool, and the gage may be set with respect to either ends of the scales 5. The spoke-shave may be used on either straight or curved pieces of wood. When desired, the gage may be completely removed from the stock 1, and the spoke shave used without the gage.

I am aware that many changes may be made, and numerous details of construction varied through a wide range without departing from the principles of this invention, and I therefore do not purpose limiting the patent granted otherwise than necessitated by the prior art.

I claim as my invention :–

The combination with a spoke-shave having similar guide grooves in the sides thereof, of a gage, means integrally formed on said gage adapted to slidably engage in said guide grooves and thus maintain the gage in slidable contact with the spoke shave, and set screws projecting through said means and adapted to engage in said grooves to hold said gage locked against movement in an adjusted position on said spoke-shave.

In testimony whereof I have hereunto subscribed my name in the presence of two subscribing witnesses.

ADOLPH P. RITTER.

Witnesses:

LAWRENCE REIBSTEIN,

SPENCER W. GIBBS.