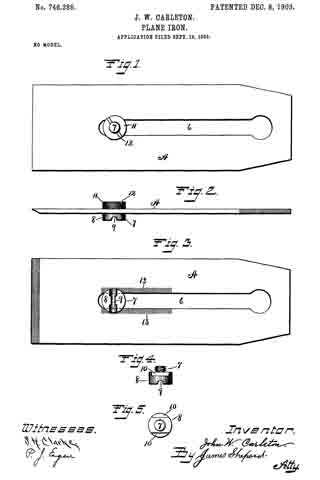

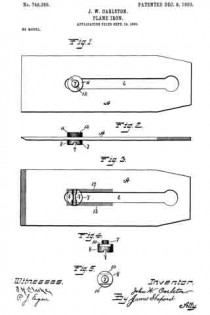

No. 763,721 – Plane-Iron-Adjusting Device (John W. Carleton And George E. Trask) (1904)

UNITED STATES PATENT OFFICE.

_________________

JOHN W. CARLETON AND GEORGE E. TRASK, OF NEW BRITAIN, CONNECTICUT, ASSIGNORS TO

UNION MANUFACTURING COMPANY, OF NEW BRITAIN, CONNECTICUT, A CORPORATION.

PLANE-IRON-ADJUSTING DEVICE.

_________________

SPECIFICATION forming part of Letters Patent No. 763,721, dated June 28, 1904.

Application filed October 26, 1903. Serial No. 178,477. (No model.)

_________________

To all whom it may concern:

Be it known that we, JOHN W. CARLETON and GEORGE E. TRASK, citizens of the United States, residing at New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Plane-Iron-Adjusting Devices, of which the following is a specification.

Our invention relates to improvements in plane-iron-adjusting devices; and the object of our improvement is convenience and efficiency in use.

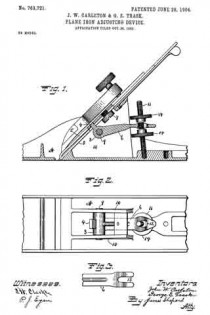

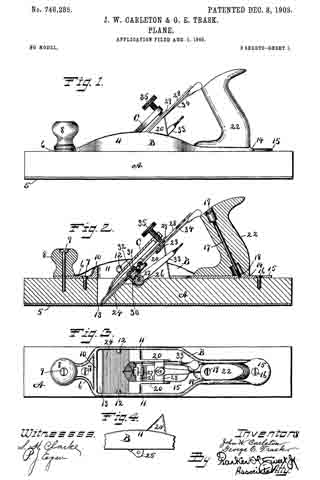

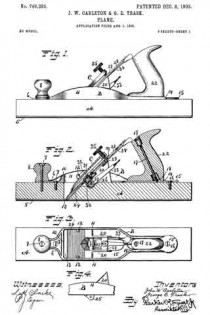

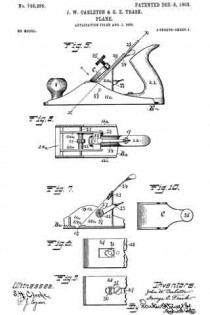

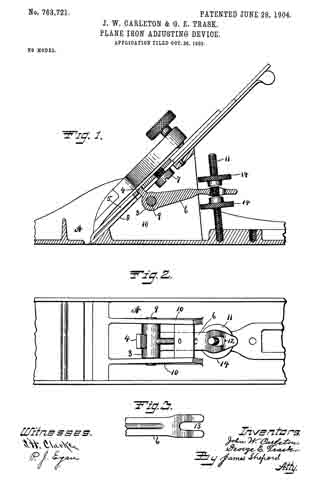

In the accompanying drawings, Figure 1 is a sectional side elevation of our plane-iron adjustment, together with so much of a plane as is deemed necessary to show its connection therewith. Fig. 2 is a plan view of the major part of the said adjusting devices and a portion of the plane-stock, the upper adjusting-nut and the plane-irons being removed. Fig. 3 is a plan view of the longer arm of the operating-lever in a modified form.

Our improvement relates to the longitudinal adjustment of the plane-iron or cutting-bit when frictionally held in place on its seat by a bit-clamp.

A designates the stock, which may be of any known or ordinary construction.

3 is the hub of the operating-lever, the said lever having a short arm or tooth 4 for engaging the cap-iron 5 and a longer operating-arm 6 by which to move the said lever. The cap-iron 5 is secured by a screw 7 to the plane-iron or cutting-bit 8 in the ordinary manner, so that when in use the said cap is rigid with the plane-iron, whereby moving the cap longitudinally also moves the plane-iron longitudinally. Any known connection of the short arm or tooth of the lever with the plane-iron may be substituted for the cap connection therewith which is herein shown. The plane-iron 8 is seated in the ordinary position on a fixed seat of the stock A, and underneath this plane-iron the operating-lever 3 4 6 is pivoted in any proper manner — as, for example, by the pin 9, which extends through the hub 3 of the said lever and uprights or supports 10 of the stock. The longer arm 6 of the operating-lever is provided with an opening for the admission of the screw-post 11 that is rigidly mounted on the stock and projects upwardly at substantially a right angle to the length of the said operating-arm when the said arm is in its central or intermediate position. This opening may be in the form of a slot 12 near the outer end of the said arm, as shown in Fig. 2, or a notch 13, that extends from the outer end of the said arm inwardly, as shown in Fig. 3. Two separate adjusting-nuts 14 are mounted on the screw-post 11, one of the said nuts being above the operating-arm and the other below it. The upper one of these nuts is removed in Fig. 2.

The operating-lever, substantially as herein shown and described, without the screw-post and nuts is older than the date of the invention upon which this application is based, and hence the said lever of itself is not claimed herein.

The outer end of the longer arm 6 of the operating-lever constitutes a handle by means of which the lever when free may be moved in either direction. The two separate adjusting-nuts 14 are each single-acting nuts for acting on one side only of the lever. The friction of the ordinary bit-clamp is depended upon to hold the cutting-bit and the operating-lever in their places when one or both of the nuts are out of contact with the said lever.

With our improvement when both nuts are turned so as to bear snugly against the opposite sides of the longer arm of the operating-lever the said lever is positively held against moving in either direction. If it is desired to raise the outer end of the operating-arm for adjusting the plane-iron downwardly and outwardly, the upper nut is loosened a little and the opposing or under nut tightened up, and vice versa. The operator can readily see which way to move the nuts to effect the desired adjustment. Some workmen never lay away the plane without first drawing the plane-iron inwardly so as to protect its cutting end. Then when they begin work again the plane-iron has to be readjusted. With our adjustment when it is desired to draw in the plane-iron to protect the cutting end it is only necessary to loosen the lower nut a little and then depress the outer end of the operating-arm by the application of one’s finger or thumb without moving the upper nut at all. Then when the plane is again wanted for use it. is only necessary to raise the operating-arm of the lever by means of the handle until it is stopped by the upper nut. Then bring the lower nut up into place to bind the said arm against the upper nut and the cutting-bit will be restored to the particular adjustment that it had when laid away. In this connection it may be noted that there is a complete and operative combination with the outer nut only, the upper nut as herein shown-that is to say, when the lower nut is run down so as to be out of action the lever may be brought up against the upper nut as a stop, and the cutting-bit will be thus adjusted to whatever position the said nut may be set and with substantially the same degree of fineness that can be had with the ordinary double-acting nut that always leaves the lever free in one direction to a limited extent. Thus when only the upper one of the nuts is employed and the desired adjustment has been made the operator may depress the lever to draw in the edge of the cutting-bit for laying the plane away and on resuming work may force the cutting edge out again by merely raising the handle until the lever strikes the said upper nut. The friction caused by the bit-clamp will hold the bit in its adjusted positien, and it will be adjusted with a fair degree of accuracy. By the use of the two single-acting nuts, when both are firmly seated in place, all the give or spring of the parts is taken up so as to make the adjustment positive. Now by first loosening one nut and then tightening up the other to move the lever either way from this positive or rigid adjustment we are enabled to adjust the cutting-bit with the iinest kind of action. At the same time the lower nut may be readily spun down out of the way for permitting the cutting-bit to be moved in and out by hand in the manner before described.

It is apparent that some changes from the specific construction herein disclosed may be made, and therefore we do not wish to be understood as limiting ourselves to the precise form of construction shown and described, but desire the liberty to make such changes in working our invention as may fairly come within the spirit and scope of the same.

We claim as our invention —

1. In a plane, the combination of a cutting-bit with a bit-clamp for frictionally holding the said bit in place on its seat, a lever for moving the said cutting-bit longitudinally on its seat under the said bit-clamp, the said lever having a short arm connecting it with the said cutting-bit, and a longer operating-arm having a handle, a fixed screw extending in the line of movement of the said operating-arm and a single-acting nut mounted on the said screw at the outer side of the said arm and acting on the said side only, leaving the lever free to be moved by the handle in the direction for withdrawing the edge of the cutting-bit substantially as described.

2. In a plane, the combination of a cutting-bit with a bit-clamp for frictionally holding the said bit in place on its seat, a lever for moving the said cutting-bit longitudinally on its seat under the said bit-clamp, the said lever having a short arm connecting it with the said cutting-bit and a longer operating-arm having a handle, a fixed screw extending in the line of the movement of the said operating-arm, a single-acting nut mounted on the said screw at one side of the said operating-arm for acting on that side only, and a second single-acting nut mounted on the said screw at the opposite side of the said operating-arm for acting on that side only, substantially as described.

JOHN W. CARLETON.

GEORGE E. TRASK.

Witnesses:

N. G. CURTIS,

H. H. WHEELER.