No. 141,828 – Improvement In Crozing And Chamfering Planes (Allen M. Strattan) (1873)

UNITED STATES PATENT OFFICE.

_________________

ALLEN M. STRATTAN, OF LADOGA, INDIANA.

IMPROVEMENT IN CROZING AND CHAMFERING PLANES.

_________________

Specification forming part of Letters Patent No. 141,828, dated August 12, 1873; application filed March 22, 1873.

_________________

To all whom it may concern:

Be it known that I, ALLEN M. STRATTAN, of Ladoga, in the county of Montgomery, Indiana, have invented an Improvement in Crozing and Chamfering Planes, of which the following is a specification:

This is an improved tool for coopers’ use, and combines the functions of a croze and a charnfering-plane.

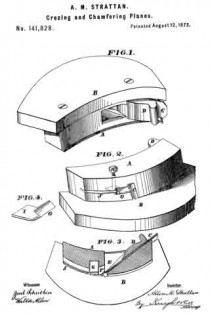

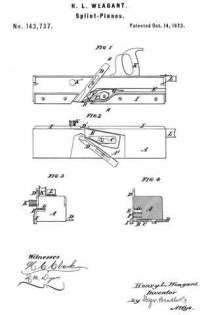

Figure 1 is a perspective view of a tool embodying my invention. Fig. 2 is a perspective view of the same reversed. Fig. 3 is a section of my tool taken parallel with the fence-board. Fig. 4 shows my croze-bit detached.

A is a stock and B its fence-board, similar in general conformation to those of a customary chamfering-plane, C being the chamfering-bit and D the wedge. A peculiarly-shaped excavation, E F, in the stock serves as the combined throats of both the chamfering-bit C and a “crow” or crozing-bit, G, whose form is clearly shown in Fig. 4. This crozing-bit is secured by a set-screw, H, tapped into the under side of the stock, and which serves to nip the said bit by its shank I. Embedded into the convex-working face of the stock in advance of, and in line with, the croze-bit G, is a guide bar or tongue, J.

My tool is used in the common way of crozing plows,the fence-board resting upon the edge of the chine and the croze-bit, and chamfer-bit operating simultaneously to both croze and chamfer the chine.

Before using this plane the top of the vessel is leveled by the common block-plane. Then I proceed by placing the chamfering-plane on the top of the vessel, and rotating the plane forward and backward until the croze is cut to a sufficient depth. The chine is finished at the same operation.

I claim as new and of my invention —

The combination of the stock A E F, fence-board B, and bits C and G, when constructed and arranged as herein described to perform the chamfering and crozing operations simultaneously, as explained.

ALLEN M. STRATTAN.

Witnesses:

ISAAC WILLIAM ELLIS,

NATHAN STRATTAN.