| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

EDWARD HAYDOCK, OF MANCHESTER, ENGLAND.

HAND-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 750,189, dated January 19, 1904.

Application filed December 14, 1901. Serial No. 85,900. (No model.)

_________________

To all whom it may concern:

Be it known that I, EDWARD HAYDOCK, a subject of the King of Great Britain, residing at 75 Ackroyd street, Higher Openshaw, Manchester, in the county of Lancaster, England, have invented a new and useful Improved Hand-Plane, of which the following is a specification.

This invention relates to hand-planes for woodworking, particularly pattern-making, in which curves and other irregular forms are required to be produced in patterns and core-boxes and other like work.

The object of my invention is to enable plane-irons with diiferent forms of cutting edges to be employed in a metallic stock having a flat sole in combination with a wood sole that is capable of being fixed to or removed therefrom, whose face is either formed to any preferred curve or of other required shape, and to provide means for holding said sole firmly in position; also, quick and automatic adjustment of the plane-iron.

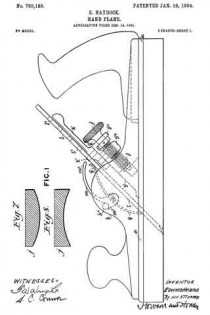

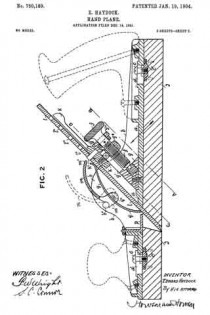

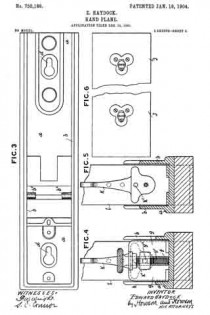

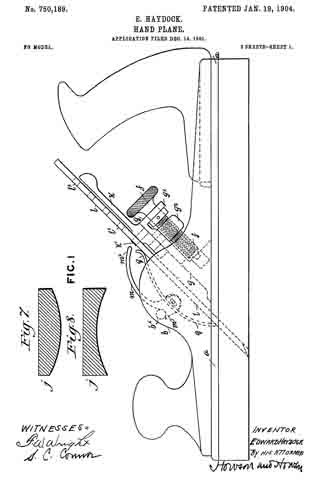

In the accompanying drawings, illustrating my invention, and to which I hereinafter refer, Figure 1 is a side view, and Fig. 2 a longitudinal section, of my improved plane. Fig. 3 is a plan of the stock-sole with the plane-iron and adjustments removed. Fig. 4 is an angular transverse section on line A B, and Fig. 5 a like section on line C D as seen in the direction of the arrow in Fig. 2. Fig. 6 is a plan of adjustable sole. Fig. 7 is a cross-section of a detachable convex wood sole for planing the inside of a cylinder, while Fig. 8 is a view of a concave sole for planing the outside of cylindrical bodies.

In the views the same letters refer to like parts.

According to this invention I form a metallic stock of malleable iron or steel, either cast or pressed, or other preferred metal, having key-shaped holes therein, as shown at d on plan in Fig. 3. These holes, are for the reception of small studs or set-screws c, which are fastened in small castings, as c’, fixed in an adjustable wood sole, as j. (Shown in Figs. 2 and 6.) The position of these castings in the adjustable sole corresponds with the holes in the stock-sole a. The facing on the upper side of the key-shaped holes d in the stock-sole is slightly taper to insure the screws c drawing the adjustable sole perfectly tight and rigid to the stock-sole when it is fitted thereon. The adjustable soles may be flat for ordinary smooth, jack, or trying plane purposes, or they may be of any required shape or radius for curves, core-boxes,or like work, as shown in Figs. 7 and 8. I fix a triangular slide g between the side walls b of the stock by means of screws inserted in the stock-sole.

The holes for the screws are slightly elongated to permit the slide to be moved a little backward or forward in order to alter the pitch of the plane-iron for planing different kinds of wood, either with or across the grain, as required. The aforesaid slide has a slot g’ formed lengthwise in its angular face, through which a square-headed stud g2 is passed. Said stud is square under the head and has a hole through the head, with a screw-thread formed therein. The projecting end of the stud is screwed or loosely riveted into a carrier or adjusting-lever k, which carries aplane-iron, as l, by means of a pin k’, that enters one of the small holes l’, formed at equal distances along the center of the plane-iron if a single iron is employed for radii or curved work or into a small hole in the back iron for ordinary planing. The aforesaid stud, with the plane-iron, is raised and lowered by a screw f, which is passed through the head of the stud g2, the neck of the screw being held in a lug gx at the top of the slide g and the bottom end resting in a footstep in said slide. The plane-irons are set square by the adjusting-lever k being turned a little to one side or the other and are held firmly in position by a curved spring q, the ends of which are pressed against the face of the plane-iron by a cam-lever m, the lower end of which is formed with a curved projection m’ at each side and hinged to the center of the aforesaid spring, as shown at qx in Fig. 2. A lug bx projects inwardly from each of the side walls of the plane, under which the curved projections m’ are placed when the lever m is in the position shown by dotted lines. When the free end mx of the lever is turned down, as shown, the spring q is compressed and the ends pressing on the face of the plane-iron keep it firmly in position, perfect and rapid means of adjustment being thereby obtained. The mouth of the plane if employed as an ordinary metallic plane without wood soles may be enlarged or reduced by a metallic slide p, fitted to the stock-sole by a stud passing through an elongated hole and secured by a nut. By these means a direct positive motion is obtained for forward feed and lateral adjustment of plane-iron, and if one iron is, ground to a two and one-half inch radius it would also work to any radius extending to about four inches without regrinding or altering. A quarter of a turn of the screw f would give one one-hundred-and-twelfth part of an inch, or thereabout, forward adjustment of the plane-iron, and by the lateral adjustment the inconvenience of exercising great care in sharpening or grinding the iron to correct form is avoided.

A sole-plate to do any kind of special work that is usually done by special planes may be made by the workman himself and fixed in the manner described for use as an ordinary smooth, jack, or trying plane.

I claim as my invention —

1. A hand-plane consisting of a metallic stock with keyhole-slots in the stock-sole, the enlarged opening of the keyhole being toward the front of the stock-sole, wooden soles carrying screws adapted to be passed through the keyhole-slots and inclined wedge-surfaces on one of the parts, whereby, upon forcing the metal stock forward the wooden sole will become secured to the metallic stock and by striking the rear of the sole it will become detached, substantially as described.

2. A hand-plane having a metallic stock with a flat sole-face, elongated recesses in said sole and a number of separate wood soles, each having a fiat surface and projections thereon adapted to fit into aforesaid recesses, the projections fitting the forward portion of said recesses loosely and fitting the rear portion tightly so that the sole may be slid against the surface of the stock to secure the wood sole to the metallic stock, whereby on striking the rear of the sole it will become detached, substantially as described.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

EDWARD HAYDOCK.

Witnesses:

THOS. PRESCOTT,

JNO. HUGHES.