No. 380,811 – Chisel-Gage (Charles L. Mead) (1888)

UNITED STATES PATENT OFFICE.

_________________

CHARLES L. MEAD, OF NEW YORK, N. Y., ASSIGNOR TO

THE STANLEY RULE AND LEVEL COMPANY, OF NEW BRITAIN, CONNECTICUT.

CHISEL-GAGE.

_________________

SPECIFICATION forming part of Letters Patent No. 380,811, dated April 10, 1888.

Application filed January 26, 1888. Serial No. 261,982. (No model.)

_________________

To all whom it may concern:

Be it known that I, CHARLES L, MEAD, a citizen of the United States, residing at New York, in the county of New York and State of New York, have invented certain new and useful Improvements in Chisel-Gages, of which the following is a specification.

My invention relates to improvements in chisel-gages for use in blind-nailing, and the main object of my improvement is to prevent the shaving turned up from breaking off.

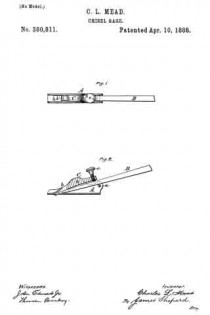

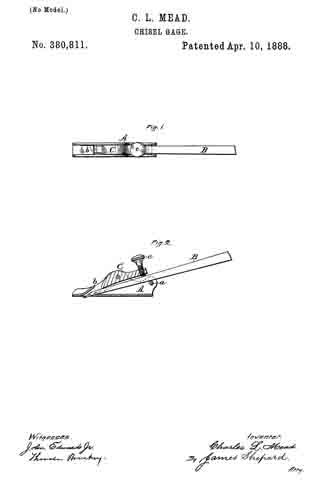

In the accompanying drawings, Figure 1 is a plan view of my gage with a portion of a chisel to which the gage is attached, and Fig. 2 is a central longitudinal section of said gage with a side elevation of said portion of a chisel.

In blind-nailing a narrow shaving is raised up from the surface of the wood, a nail or brad then driven into the wood at the place from which the shaving was raised, and then the shaving is glued and turned back to cover the nail-head. My gage is designed for attachment to a chisel for such use.

I prefer to form the body A of sheet metal from a flat blank bent up at each side into a trough-shaped body, as shown. The bottom of this trough-shaped body is the gaging-surface, and is provided with a throat, through which the cutting-edge of the chisel-blade B may project and on the rear edge of which it may rest, as shown. The chisel-blade also rests upon the cross pin a.

Immediately above and forward of the rear edge of the throat there is a rearwardly and upwardly inclined guard, b, the same being nearly or quite parallel to the front face ofthe chisel-blade at its forward end. As illustrated, this guard is turned up from the bottom face of said sheet-metal body, the metal being merely slit at the end and sides of the guard to enable it to be thus turned up. While I prefer to thus form the body and guard of sheet metal, it is evident that the same form of body and guard might be made of cast metal.

The gage is held in place on the chisel-blade by the clamping mechanism, which consists of the pivoted clamping-lever C and its screw c.

The guard b prevents the shaving from rolling up as it is raised from the wood; in other words, it is not bent on as short a curve as it would be without said guard, and consequently it is less liable to be broken off before or when putting it back into place for covering the nail-heads.

I claim as my invention–

1. The herein-described gage for chisels, the same consisting of the body, the clamping mechanism for attaching it to a chisel-blade, and a guard immediately above and forward of the rear edge of the throat in th under side of said body and extending rearwardly and upwardly, substantially as described, and for the purpose specified.

2. The herein-described gage for chisels, the same consisting of the body and clamping mechanism for attaching the gage to a chisel-blade, said body being formed of sheet metal and having the guard b bent upwardly from the bottom face of said sheet-metal body, substantially as described, and for the purpose specified.

CHARLES L. MEAD.

Witnesses:

H. S. WALTER,

JAMES SHEPARD.