No. 749,827 – Bench-Plane (Eric O. Sjolander) (1904)

UNITED STATES PATENT OFFICE.

_________________

ERIC O. SJOLANDER, OF DEEPWATER, TEXAS.

BENCH-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 749,827, dated January 19, 1904.

Application filed June 11, 1903. Serial No. 161,054. (No model.)

_________________

To all whom it may concern:

Be it known that I, ERIC O. SJOLANDER, a citizen of the United States, residing at Deepwater, in the county of Harris and State of Texas, have invented a new and useful Bench-Plane, of which the following is a specification.

This invention relates generally to bench-planes, and more especially to means for adjusting the bit in the stock and means for securing the bit in adjusted position.

One object of the invention is to provide in a bench-plane an improved form of mechanism for adjusting the position of the bit in the stock, so that the depth of cut may be accurately adjusted and so that the edge of the bit may be brought into perfect parallelism with the face of the stock.

A further object of the invention is to provide in a bench-plane a bit bearing a scale and a bit-clamping plate bearing an indicator to cooperate with the scale on the bit to show when the bit and the clamping-plate have been brought into proper relation.

A further object of the invention is to provide in a bench-plane single means for adjusting the depth of the cut and for swinging the bit laterally on a suitable fulcrum to bring the cutting edge into parallelism with the stock.

In attaining the objects above stated and others which will hereinafter appear I make use of the construction and combination of parts of a bench-plane hereinafter described and claimed, and illustrated in the accompanying drawings, in which corresponding parts are designated by the same characters of reference throughout, it being understood that changes in the form, proportions, and exact mode of assemblage of the elements may be made without departing from the spirit of the invention.

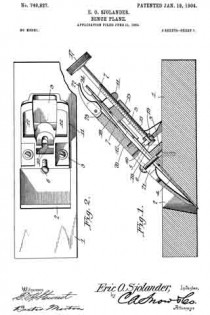

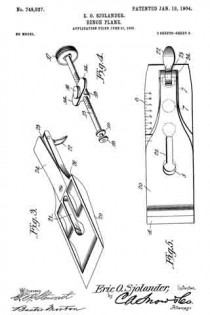

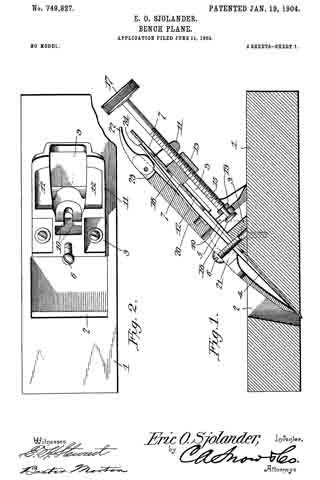

In the drawings, Figure 1 is a view in vertical longitudinal section through the plane. Fig. 2 is a view of the plane-stock and bit-support. Fig. 3 is a view in perspective of the bit-clamping plate, showing the recessed back. Fig. 4 is a perspective view of the adjusting screw and block. Fig. 5 is a plan view of the bit and the bit-clamping plate, showing the clamping-plate adjusted in position by means of the scale on the bit.

Referring to the drawings in detail, 1 designates the plane-stock, which may be of wood or metal and of any of the ordinary forms. The stock is provided with the usual opening 2 for the passage of the bit, and on the upper surface of the stock, at the rear margin of the opening 2, is provided a supporting structure 3, the forward surface of which forms a continuation of the rear wall of the opening 2. The bit 4 consists, preferably, of a single plate of steel provided at its lower end with a cutting edge and having at 5 a slot with enlarged and rounded ends for the passage of the head of a screw 6, mounted in the lower end of the supporting structure. The width of the slot 5 between the rounded end portions is of such width as just to permit of the passage of the shank of the screw 6, which is designed to serve as a fulcrum, upon which the bit 4 may be swung laterally. The bit is provided near the butt with round openings 7, for purposes that will presently appear, and along one lateral margin of the bit is formed a scale 8, for use in connection with an indicator formed on the bit-clamping plate.

The supporting structure 3 is vertically slotted at 9 from the upper end almost to the base, and at the lower end of the slot 9, which tapers slightly toward the bottom, are provided a pair of oppositely-disposed ribs 10, which lie in a plane substantially at right angles with the front surface of the support. At either side of the slot 9 is an arm 11, on the forward surface of each of which is formed a shallow recess 12 to form a way for the movement laterally and transversely of the support of one of the wings 14 of a block: 13, which is carried on the screw 15, which is supported in the slot 9 in a manner presently to be explained.

The body portion of the block 13 is sufliciently narrow to be susceptible of considerable lateral movement in the slot 9, and the wings 14 are of such proportions that they will have a similar degree of lateral movement in the recesses 12. On the forward surface of the block 13, which lies substantially flush with the forward surface of the supporting structure 3, is provided a stud 16, which is adapted for engagement with either of the round openings 7 in the plane-bit. When the parts of the plane are assembled, the stud 16 will always be brought into engagement with one of the openings 7, and when the parts are so connected the movements of the block 13 will be communicated to the bit, and conseqently any shifting of the block 13 will change the position of the bit correspondingly.

The screw 15, upon which the block 13 is carried, is provided at its upper end with a head 17 of suitable form to facilitate the rotation of the screw, and at the lower end the screw has a reduced portion which is not threaded. At the extremity of the reduced portion a collar 18 is rigidly attached, and loose upon the reduced portion between the collar 18 and the threaded portion of the screw is a second collar 19. The opposite faces of both collars 18 and 19 are rounded, as best seen in Fig. 1, and when the collars are spread apart sufficient space is provided between them to permit the passage of the ribs 10, which are spaced apart sufficiently to allow the reduced portion of the screw to be introduced between them. The rounded faces of the collars 18 and 19 permit the screw 15 to be shifted laterally with the reduced portion between the ribs 10 as a pivotal point.

In order to clamp the bit 4 rigidly in proper relation to the stock 1, I provide a bit-clamping plate 20 of the form generally used, which is provided about midway of its length with a slot 21, having the lower end thereof enlarged and rounded to permit the passage of the head of the screw 6. At the upper end of the bit-clamping plate a cam-lever 22 is pivotally mounted in a slot 23 in the clamping-plate, and on the rear surface of the clamping-plate, which is preferably recessed, as shown in Fig. 3, there is provided near the upper end of the plate a tongue 24, of thin metal, which is rigidly attached at its lower end to the clamping-plate and has the upper end thereof, which is free, disposed under the cam on lever 22. The tongue 24 is provided to prevent the contact of the cam with the bit 4, as the contact of the cam with the bit would tend to throw the bit out of adjusted position.

On the side of the clamping-plate 20 which corresponds in position to the scale 8 on the bit there is formed a shoulder 26, which is adapted to serve as an indicator in connection with said scale and to show by the coincidence of the shoulder with one of the divisions of the scale when the clamping-plate has been brought into proper relation to the bit.

In assembling the parts of the plane for use the mode of procedure is as follows: The clamping-plate 20 and the bit 4 will first be brought into proper relation, as shown in Fig. 5, and the division of the scale with which the shoulder on the clamping-plate coincides will be noted. The bit will then be introduced into the opening in the stock, and the stud 16 on the block 13 will be brought into engagement with one of the openings 7 in the bit. If the bit is new and unworn, the lower opening will be employed, and if the bit is old and much worn the upper opening will be used. The bit having been operatively connected with the block 13, the screw 15 will be rotated by means of the head 17 on the end thereof until the edge of the plane-bit has been protruded beyond the face of the stock to the distance required for the proper depth of cut. Then the screw 15 will be swung laterally, if necessary, to bring the edge of the bit into perfect parallelism with the face of the stock. During the adjustment the operator will hold the plane in such position that the relation of the edge of the bit with the face of the stock may be accurately observed. When the bit has been properly adjusted, the clamping-plate 20 will be placed in position on the forward surface of the bit, with the screw 6 extending through the opening 21 in the plate. The clamping-plate will then be brought into exact position in relation to the bit by causing the shoulder 25 to coincide with the division of the scale 8, previously noted, and the cam-lever 22 will then be operated to secure the clamping-plate in adjusted position.

From the foregoing description of the construction and mode of adjustment of the plane it will be seen that the adjustment of the bit in relation to the plane-stock is effected independently of the adjustment of the clamping-plate and that the relative positions of the clamping-plate and bit to produce the desired result having been noted at the beginning of the operation of adjustment of parts of the plane the clamping-plate may be brought at once into proper relation to the bit and secured without deranging the adjustment of the bit in relation to the stock. It will also have been observed that by providing a scale on the bit and an indicator of a suitable form on the clamping-plate a degree of accuracy of adjustment of the clamping-plate and bit may be secured, which is impossible in planes not so constructed.

A special advantage inherent in the construction hereinbefore described is in the mode of supporting the screw 15 and the adjusting-block 13, by which it is made possible to effect the adjustment of the plane-bit as to depth of out and as to parallelism with the face of the stock by a single adjusting means.

Having thus described the construction and operation of my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. In a bench-plane, the combination of a bit bearing a scale located above the mouth of the plane, and a bit-clamping member having an indicator adapted to cooperate with said scale.

2. In a bench-plane, the combination of a bit bearing a scale above the mouth of the plane, and a clamping member having a shoulder adapted to form an indicator for cooperation with said scale.

3. In a bench-plane, the combination of a bit having a scale located along one lateral margin thereof above the mouth of the plane, and a clamping member having an indicator adapted to cooperate with said scale.

4. In a bench-plane, the combination of a bit, a support for the bit having a slot within its supporting range, a block supported in said slot and susceptible of movement longitudinally and laterally therein, said block being adapted for positive connection with the bit, and a pivoted member mounted within said slot along which said block is longitudinally movable.

5. In a bench-plane, the combination of a bit, a block adapted for positive connection with said bit, and a screw upon which said block is supported, said screw being pivotally mounted to swing laterally.

6. In a bench-plane, the combination of a bit, a bit-support having a longitudinally-arranged slot, oppositely-disposed ribs provided at one end of the slot, a screw arranged in said slot having collars near one end for loose engagement with said ribs and a block mounted on said screw and adapted for lateral and longitudinal movement in said slot and also adapted for positive connection with said bit.

7. In a bench-plane, the combination of a bit, a bit-support having a longitudinaly-disposed slot, oppositely-disposed ribs, at the lower end of said slot, a screw arranged in said slot and having at the lower end collars spaced apart and having the opposite faces rounded for engagement with said ribs, and a block mounted on said screw and adapted for positive connection with said bit.

In testimony that I claim the foregoing as my own I have hereto affixed my signature in the presence of two witnesses.

ERIC O. SJOLANDER.

Witnesses:

J. H. JOCHUM, Jr.,

J. ROSS COLHOUN.