No. 153,399 – Improvement In Bench-Planes (George M. Thompson) (1874)

UNITED STATES PATENT OFFICE.

_________________

GEORGE M. THOMPSON , OF BOSTON, MASSACHUSETTS.

IMPROVEMENT IN BENCH-PLANES.

_________________

Specification forming part of Letters Patent No. 153,399, dated July 21, 1874; application filed June 13, 1874..

_________________

To all whom it may concern:

Be it known that I, GEORGE M. THOMPSON, of Boston, in the county of Suffolk and State of Massachusetts, have invented a new and valuable Improvement in Bench-Planes; and I do hereby declare that the following is a full, clear, and exact description of the construction and operation of the same, reference being had to the annexed drawings making a part of this specification, and to the letters and figures of reference marked thereon.

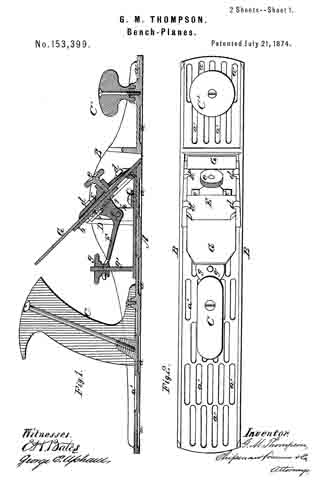

Figure 1 of the drawing is a representation of a longitudinal vertical section of my plane. Fig. 2 is a top plan view, and Fig. 3 is a bottom plan view. Fig. 4 is a transverse section, and Figs. 5, 6, and 7 are detail views. Fig. 8 is an under-side view of the chip E.

This invention has relation to that class of bench-planes having metallic stocks; and it consists, principally, in a bed-frame and moveable carriage for the plane-iron, which carriage is adjustable by means of a rack and segment lever and a thumb-screw, and affords a broad and firm bearing for the plane-iron. It further consists in combining, with the plane-iron and its adjustable bed, a jointed “chip” or wedge, which is provided with a set-screw, by means of which the upper and lower ends of the said chip can be made to bear with considerable force upon the plane-iron, and rigidly hold it in place. My invention consists, further, in constructing V-shaped lugs on the plane-iron carriage, which lugs are adapted to enter notches made in the edges of the plane-iron, and thereby prevent the same from slipping longitudinally when adjusted on its carriage, as will be hereinafter more fully explaned.

The following is a description of my improvements:

In the annexed drawings, A designates a sole-plate, and B B the side flanges or cheeks thereof, which, with the plate, constitute a metal plane-stock, which is cast entire. C and C’ designate the handles of the stock, which are of the usual well-known form, and are secured on top of the sole-plate in any suitable manner. The bottom and top surfaces of the sole-plate are constructed with numerous grooves, a, arranged alternately in regular rows of short sections, which greatly reduce the frictional surface, while at the same time they lighten the stock very much. The grooves a’ on top of the sole-plate are disposed between the grooves a, and also lighten the stock without materially reducing its strength or stiffness. The said grooves run in a direction with the length of the stock, and they are preferably made quite short, so that they will not interfere with the dressing of the edge of a very narrow piece of stuff. D designates a frame, which is rigidly secured upon the sole-plate A, in rear of the throat, by means of a clamp, c. This frame D is constructed with a bearing, b’, for the lower portion of the plane-iron G, the upper portion of which iron is supported upon an inclined carriage or sliding bed, b. This carriage b is guided in the frame D by means of lips p p and hooking-lugs l l, (shown in Fig. 6,) and it is constructed with V-shaped lugs j j, which enter notches i i made in the edges of the plane-iron G, and thus prevent endwise displacement of the plane-iron on its carriage. On the bottom side of the carriage b a rack, r, is formed, the teeth of which engage with a toothed segment, which is formed on the short arm of a lever, F, which has its fulcrum at f on standard h, rising from the base of the frame D. The longer arm of lever F is forked, and embraces an annular groove in an adjusting-nut, g, which nut is applied on a screw, g’, rising perpendicnlarly from a rear extension of the base of frame D. By adjusting the nut g, the carriage b can be moved up and down in the frame D, and the plane-iron can be nicely adjusted according to the thickness of the shaving required. E designates what is denominated the chip, which is of wedge form, and composed of two pieces hinged together at e’, and provided with a set-screw, e. When the plane-iron G is in place on the carriage b and bearing b’, the chip is inserted between it and four hooked lugs, d d d d, after which the parts are rigidly secured in place by means of the screw e, which bears on the plane-iron, and, by centrally bowing up the joint e’, forces the ends of the chip hard down on the plane-iron, as indicated in Fig. 1.

I am aware that similar devices have heretofore been used, as shown in the patent of Leonard Bailey, dated August 6, 1867, No. 67,398, and therefore I do not make claim to any device therein shown.

What I claim as new, and desire to secure by Letters Patent, is —

1. The frame D, constructed with a bed-piece, b’, and provided with an adjustable carriage, D, for the plane-iron provided with the rack r, and combined with cogged segment-lever F and adjusting-nut g, substantially as and for the purpose described.

2. The jointed chip E, provided with a set-screw, e, combined with the frame-lugs d, and the plane-iron G upon its carriage b, arranged as described.

3. The carriage b, provided with lugs j, combined with al plane-iron having notches i i in the edges to correspond therewith, substantially as in the manner shown and described.

In testimony that I claim the above I have hereunto subscribed my name in the presence of two witnesses.

GEO. M. THOMPSON.

Witnesses:

GEORGE E. UPHAM,

FRANK J. MASI.