No. 165,742 – Improvement In Joiners’ Planes (Joseph Look) (1875)

UNITED STATES PATENT OFFICE.

_________________

JOSEPH LOOK, OF SOUTH ABINGTON, MASSACHUSETTS, ASSIGNOR TO BRIGHAM, LITOHFIELD & VINING, OF SAME PLACE.

IMPROVEMENT IN JOINERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 165,742, dated July 20, 1875; application filed March 15, 1875.

_________________

To all whom it may concern:

Be it known that I, JOSEPH LOOK, of South Abington, of the county of Plymouth and State of Massachusetts, have invented a new and useful Improvement in Joiners’ Planes; and do hereby declare the same to be fully described in the following speciiication and represented in the accompanying drawings, of which —

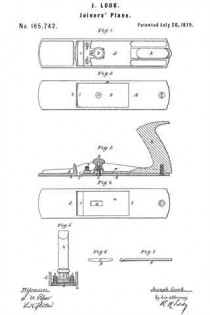

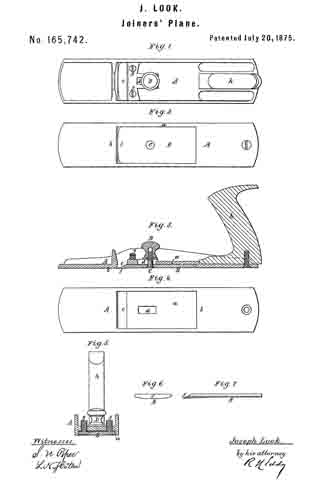

Figure 1 is a top view, Fig. 2 a bottom view, and Fig. 3 a longitudinal section, of one of my improved planes. Fig. 4 is a bottom view, and Fig. 5 a transverse section, of the stock. Fig. 6 is a front-end view, and Fig. 7 an edge view, of the cutter or plane-iron, which is crowned or curved transversely on its lower surface for some distance back from the cutting-edge.

The plane is designed for cutting or planing across the grain of wood perpendicularly, or about so, thereto. Instead of arranging the cutting-iron sloping in the stock, or at an acute angle to the bearing-surface of the plane, it is disposed substantially or approximately parallel thereto, and is wholly arranged within the stock, or a cavity or recess made lengthwise therein, the cutter being on its under surface, and at and back from its cutting edge, arched or crowned a little transversely, as shown.

In the drawing, A denotes the stock, made with a cutter-receiving recess, a, arranged in it, and with respect to its bearing-face b, in manner as shown, there being a chip-throat, c, leading upward out of said recess a and through the stock, in manner as represented. Besides the said throat c, there is a slot, d, arranged lengthwise in the stock, and to open upward out of the recess a. The cutter or plane-iron shown at B is placed flatwise in the recess a, and with the rear part of its lower surface flush with the bearing-surface b, the cutting-edge f projecting partly across the chip-throat. A screw, C, formed as shown, goes up through a countersunk hole in the cutter, and also through the slot d, and is provided with a clamp-nut, D, such serving to hold the cutter in place in the stock. In advance of the said screw and nut are two adjusting-screws, g g, which, arranged as shown, screw down into and through the stock and against the plane-iron, they serving to determine the projection of its cutting-edge below the bearing surface of the stock, such stock being provided with a handle, h, arranged as represented.

It will be seen, that while such a plane is being used to cut across the end or grain of a piece of wood, the cutter will stand at, or nearly at, a right angle with the said grain. and therefore will operate to much better advantage than a cutter having a slanting position in the stock, as plane-irons are usually arranged.

I prefer to curve or crown the cutter in manner as shown and described, but a plane-

surface cutter may be used. The curved one, however, for various kinds of planing, especially for reduction of vessels knees or ribs, will operate much better than a plane-surface cutter.

I claim —

In the improved plane, the cutter B, its receiving-recess a, chip-throat c, and holding and adjusting screws C D, g g, arranged in and with the slotted bottom of the stock A, all substantially as described and shown.

JOSEPH LOOK.

Witnesses:

GEORGE A. CLIFT,

ALBERT DAVIS.