No. 11,635 – Multiform Molding Plane (Thomas Worrall) (1854)

UNITED STATES PATENT OFFICE.

_________________

THOMAS WORRALL, OF MOUNT HOLLY, NEW JERSEY, ASSIGNOR TO MIFFLIN PAUL.

MULTIFORM MOLDING-PLANE.

_________________

Specification of Letters Patent No. 11,635, dated August 29, 1854.

_________________

To all whom it may concern:

Be it known that I, THOMAS WORRALL, of Mount Holly, in the county of Burlington, in the State of New Jersey, have invented an Improveinent in Carpenters’ Molding and Grooving Planes; and I do hereby declare that the following is a full and exact description thereof, reference being had to the accompanying drawings, and to the letters of reference marked thereon.

The nature of my invention consists in the application of slides, by means of plates and screws) to the plane which will render that plane capable of working all kinds of moldings rabbets and grooves.

To enable others skilled in the art to make and use my invention, I will proceed to describe its construction and operation. I make a dovetail and groove in the face of a plane, then screw or pivot a plate to the side of that plane, with holes through which screws may pass to secure the slide, I now make a slide of any pattern and put into the groove and dovetail which I secure by means of the screws which pass through the plate.

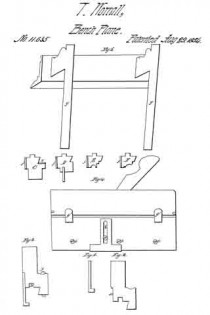

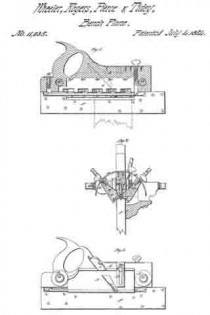

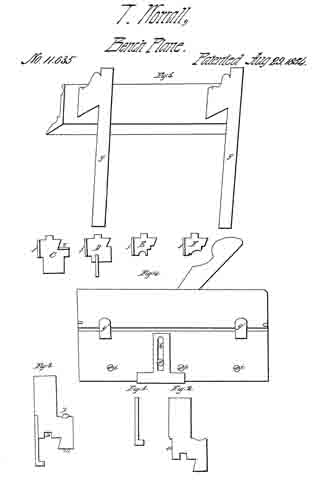

Figure 1 in the drawing is the end of the plate. Fig. 2, shows the end of the plane dovetailed and groove on the face. Fig. 1 is securely screwed or riveted to Fig. 2, at a, which forms Fig. 3, and thus forming the opening for the slide as seen on Fig. 3, at b–b. C, D, E, F are slides made to fit into this opening. Fig. 5 is the guide to a common plow, or sash filleter. Fig. 4, is the side of a plane, showing the brass, or iron plate.

g, g, on Fig. 5, should pass through the holes g, g, on Fig. 4. Now take slide C, and put it into the plane at b, b, as seen on Fig. 3 and you have a sash filleter complete; then take out slide C, and put in slide D, and you have a plow plane complete.

The stop on the side of the plane marked, h, is to regulate the depth of groove by the plow, or of the rabbet by the filleter. The two planes thus formed, are the only two requiring either the guide Fig. 5, or the stop, h. Let these be taken off, and in the place of slide D, put in slide E, and you have a common bead plane, remove that slide, and put in slide F, and you have a molding plane, and so on with every conceivable kind of plane. The only thing required to make as great a variety of moldings &c. as you please, are a new slide and a new iron to each.

The slides are made firm to the bed of the plane, by screws as seen on the plate on Fig. 4, and marked i, i, i. These pass through the plate into another plate on each of the slides, (which plate is denoted by the thick black mark on the drawings at j) and are thus screwed firmly to the plane, and if additional firmness should be required, which may be the case when the plane is required to make very wide moldings, it may be obtained by passing a, screw through the plane at k, as seen on Fig. 3, into a plate denoted on the drawings by the thick black mark at l in slide C and thus screwing the slide more firmly against the base of the plane at m, on Fig. 3.

What therefore I claim as my invention, and for which I desire security by Letters Patent, is —

The slide attached to a plane, by means of plates and screws, which will make that plane capable of working all kinds of grooves fillets and moldings.

THOS. WORRALL.

Witnesses:

R. B. NAYLER,

JOHN S. PEAK.