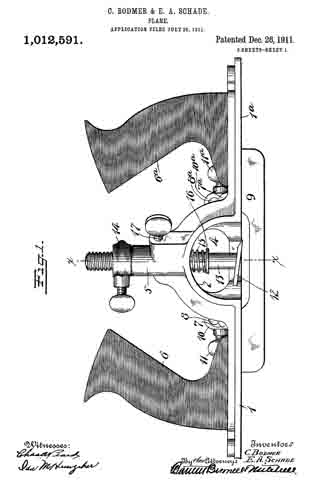

No. 1,012,591 – Plane (Christian Bodmer And Edmund A. Schade) (1911)

UNITED STATES PATENT OFFICE.

_________________

CHRISTIAN BODMER AND EDMUND A. SCHADE, OF NEW BRITAIN, CONNECTICUT, ASSIGNORS TO THE

STANLEY RULE & LEVEL COMPANY , OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE.

_________________

1,012,591. Specification of Letters Patent. Patented Dec. 26, 1911.

Application filed July 28, 1911. Serial No. 641,094.

_________________

To all whom it may concern:

Be it known that we, CHRISTIAN BODMER and EDMUND A. SCHADE, citizens of the United States, residing at New Britain, county of Hartford, State of Connecticut, have invented certain new and useful Improvements in Planes, of which the following is a full, clear, and exact description.

Our invention relates to a new type of plane adapted to a wide range of work but especially adapted to enable the user to form shallow mortises for hinges, lock face plates, latch strike-plates and the like, with the greatest ease and accuracy. The tool is also designed in such manner that hinge mortises in the jamb and on the edge of a door may be formed without the necessity of using a butt gage, since the plane is equipped with a gage that obviates the use of a separate instrument for the marking out of the mortises. The construction is also such that a mortise may be readily formed in a rabbeted door jamb close to the face of the strike or stop, while the cutter arrangement and length of the plane allows of the forming of a mortise from one and a half inches in length to six inches in length, and also within a few inches, for example, five inches, of the upper casing or lower sill of a door casing. By a very simple adjustment, mortises longer than six inches may be made. The plane may also be used to advantage as a router, and, in the particular form shown herein, can effectively work two inches below the sole of the tool, thus giving a greater range of effective operation than possible with the ordinary router plane. With this outline, it will be seen that the plane is capable of a wide range of usefulness.

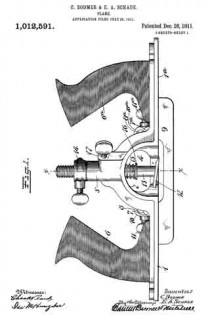

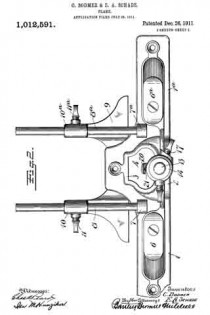

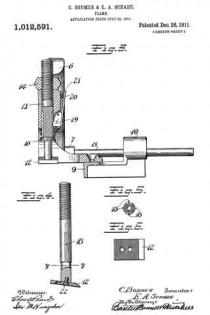

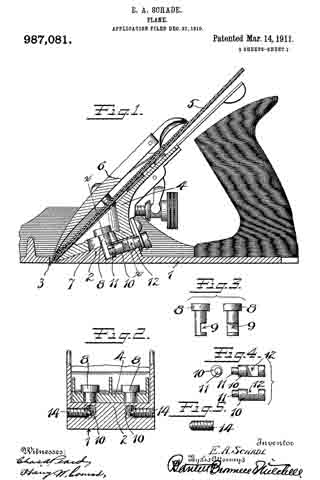

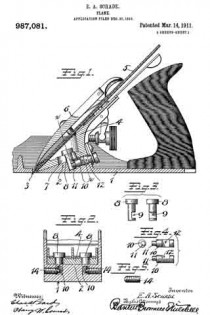

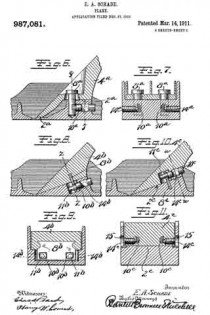

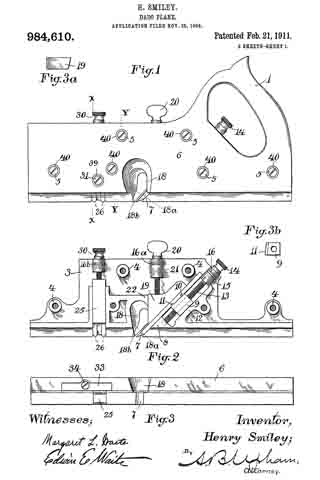

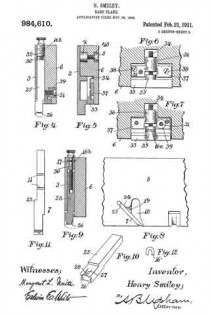

In the drawings Figure 1 is a side elevation of the plane. Fig. 2 is a plan view thereof. Fig. 3 is a section on the line x–x, Fig. 1. Fig. 4 is a side elevation of a detail. Fig. 5 is a section on the line y–y Fig. 4, looking up. Fig. 6 is a plan view of the cutter detached.

1–1a represent the two end sections of the sole of the plane.

2 is a connecting arch extending vertically from the plane of the sole sections 1–1a.

3 is a connecting arch extending horizontally from the sole sections 1–1a.

4 is a chip clearance passage between the arches 2–3.

5 is an upwardly extending tubular guide sleeve located above the arch 2.

6–6a are oppositely facing handles mounted on the two end sections 1–1a of the sole.

7–7a are bosses screw-threaded to receive horizontally extending guide rods 8–8a, when it is desired to use a gage.

9 represents a side gage having sleeves 10–10a arranged to slide upon the rods 8–8a respectively. The lower side of the arch 3 is smoothed off to form a continuation of the two sole sections 1–1a and to give a bearing of substantial width.

12 is a cutter connected to the lower end of an adjustable and slidable carrier post 13. This carrier post is mounted to slide up and down in the guide sleeve 5. The upper end of the carrier 13 is threaded and is provided with an adjustable stop 14 threaded thereon so that by rotating said stop, the downward projection of the carrier post 13 and cutter is limited.

15 is a spring arranged to press the carrier post 13 downwardly. In the preferred arrangement, this spring 15 is coiled around said post and rests at its upper end underneath the arch 2 and at its lower end against a washer 16, which may be rigidly connected to said post 13.

17 is a set screw which enters the guide sleeve 5 laterally, the inner end bearing against the carrier post 13 so that by setting up on said set-screw said post and cutter may be held against sliding movement up and down.

In the particular form shown, it will be seen that the side of the cutter carrier post 13 is provided with a plurality of longitudinal grooves 18–18.

19 is a spline carried by the guide 5, and in this instance hinged so as to be operated by a finger piece 20, said spline being suitably spring-pressed, as by a spring 21, to hold the spline projected into one of the grooves 18. In this instance, the spline and grooves are so placed that the cutting edge of the cutter 12 may be projected toward either end of the plane or laterally in either direction relative thereto. The cutter is preferably detachably connected to the carrier post 13 and is also preferably pitched downward at a slight angle. In this instance, the cutter has its upper surface cross-knurled, the lower end of the guide 13 being correspondingly knurled, so that by the aid of a fastening screw 22, said cutter may be rigidly secured to the lower end of the carrier post. As shown in Fig. 4, the cutter may have two screw passages, whereby, when the forward or cutting edge of the cutter, is worn back, the connection of the cutter to the carrier may be effected by passing the screw 22 through the second or rearmost screw passage.

In forming an ordinary shallow mortise for a hinge strike-plate or lock face-plate, incisions may be made by an ordinary chisel to determine merely the end lines of such a mortise. The gage 9 may be properly set and the cutter carrier post properly set so that it will project the cutter to the desired depth of said mortise, and no more. This being determined, the tool is then applied to the wood, and is preferably started close to the end line of the mortise facing the cutting edge of the cutter. A short chip is then taken. The operator works the plane back step by step until by taking out a succession of short chips he approaches the opposite end line of the mortise, whereupon, by pressing in on the finger-piece 20, the spline 19 is retracted and the cutter may be reversed to the position opposite from that shown in Fig. 1, whereupon the balance of the mortise may be formed without reversin the position of the plane on the piece being cut. During this operation, the cutter yieldingly engages the wood by reason of the spring pressure of spring 15, and will cut down to a depth corresponding to the desired depth of the mortise, at which depth it will be checked by the stop 14 aforesaid. When at the limit of this depth, the bottom of the mortise may be smoothed off by long strokes, so as to properly receive the part to be applied therein. By making the cutter carrier post 13 itself reversible, it is possible to work the tool in either direction in forming a mortise, without disturbing the position of the guide, and hence preserving the proper position of the cutter relatively to the mortise being formed. When the tool is to be used as a router, in some instances it is desirable to shift the tool so that the cutter will stand at right angles to the position shown in Fig. 1. This may be easily accomplished by releasing the spline 19 and shifting said carrier post 13 to the proper position. For routing at considerable depth, it may be desirable to lock the cutter post firmly against vertical movement. This may be accomplished by setting down upon the screw 17.

Obviously, cutters 12 of varying width may be substituted, depending upon the particular work to be performed and the character of wood to be operated upon.

In the above and in a variety of other ways, a mechanic skilled in the art of wood working will find this tool exceedingly useful and capable of performing, quickly and accurately, work which no other tool of the plane type is capable of performing.

What we claim is:

1. In a plane, two oppositely faced connected sole sections, an arch connecting said sections, a reversible cutter carrier, a guide in said arch for said cutter carrier, and means to permit said cutter carrier to move up and down in said guide during the operation of the plane, and disengageable means to hold said carrier against rotation at such times.

2. In a plane, two oppositely faced connected sole sections, an arch connecting said sections, a cutter carrier, a guide in said arch for said cutter carrier, means to permit said cutter carrier to yield longitudinally, said means including a spring for forcing said cutter carrier downwardly.

3. In a plane, two oppositely faced connected sole sections, an arch connecting said sections, a cutter carrier, a guide in said arch for said cutter carrier, means to permit said cutter carrier to yield longitudinally, said means including a spring for forcing said cutter carrier downwardly, and an adjusting stop coacting with said cutter carrier to check said downward movement.

4. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable and reversible cutter carrier in said arch, and a cutter mounted on said carrier in the archway of said arch and a second arch horizontally arranged and constituting a continuation of said sole sections.

5. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable and reversible cutter carrier in said arch, a cutter mounted on said carrier in the archway of said arch, a guide in said arch for said cutter carrier in which said cutter carrier is slidably mounted to permit said cutter to move up and down, and a spring operating to move said cutter in a downward direction and a stop to limit the downward movement of said carrier.

6. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable and reversible cutter carrier in said arch, a cutter mounted on said carrier in the archway of said arch, a guide in said arch for said cutter carrier in which said cutter carrier is slidably mounted to permit said cutter to move up and down, a spring operating to move said cutter in a downward direction, and an adjustable stop mounted on the upper part of said carrier.

7. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable and reversible cutter carrier in said arch, a cutter mounted on said carrier in the archway of said arch, a guide in said arch for said cutter carrier in which said cutter carrier is slidably mounted to permit said cutter to move up and down, a spring operating to move said cutter in a downward direction, an adjustable stop mounted on the upper part of said carrier, and a set screw in said guide to lock said carrier against movement.

8. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable cutter carrier in said arch, a cutter mounted on said carrier in the archway of said arch, and a second arch horizontally arranged and constituting a continuation of said sole sections.

9. In a plane, two oppositely arranged connected sole sections, an arch connecting said sections, an adjustable cutter carrier in said arch, a cutter mounted on said carrier in the archway of said arch, a second arch horizontally arranged and constituting a continuation of said sole sections, and means for connecting a substantially flat cutter to the lower end of said carrier at an angle slightly out of the plane of the bottom of the sole sections.

CHRISTIAN BODMER.

EDMUND A. SCHADE.

Witnesses:

JOSEPH M. HANCE,

TREDICK K. HINE.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________