No. 619,394 – Bench-Plane (Maschil D. Converse) (1899)

UNITED STATES PATENT OFFICE.

_________________

MASCHIL D. CONVERSE, OF NEW YORK, N. Y.,

ASSIGNOR TO JOHN J. TOWER, OF SAME PLACE.

BENCH-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 619,394, dated February 14, 1899.

Application filed June 20, 1898. Serial No. 683,931. (No model.)

_________________

To all whom it may concern:

Be it known that I, MASCHIL D. CONVERSE, a citizen of the United States, residing in the city, county, and State of New York, have invented certain new and useful Improvements in Bench-Planes, of which the following is a specification.

My present invention relates more especially to that type of bench-planes commonly made with iron stocks, and particularly to sidewise-adjustment mechanisms for the same.

Planes have been provided with mechanisms for lateral adjustment that in many cases are so constructed, disposed, and applied as to involve piercing of the bits with holes or slots or cutting of grooves longitudinally in one or the other of the flat sides thereof, requiring in consequence that the bits be made thicker and heavier than is desirable to compensate for the lack of stiffness that would result from such form in the bit and otherwise, and in other cases the construction and manner of disposing and applying such mechanisms are such that they encroach upon the radial hand-space about the handle of the plane, more especially on the front side thereof, seriously interfering with and sometimes to the injury of the hand of the operator, and by such near proximity, especially of the free ends of the operating-levers, the bits are constantly liable to be and are thereby frequently accidentally disturbed and put out of lateral adjustment.

The objects of my invention are to overcome these defects, to simplify construction, reduce the cost of manufacture, and improve the efficiency of such tools.

My invention consists in placing the fulcrum-point of a mechanism for lateral adjustment of the plane-bit at the bearing end of a cramp-screw in the outer end of the upper bit-clamp plate or in axial coincidence therewith and in so constructing and disposing all parts of said mechanism that the objects above stated will be attained, all of which will hereinafter be fully described and claimed.

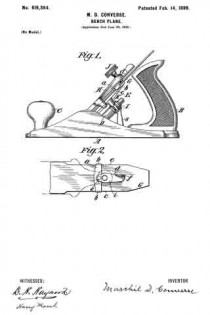

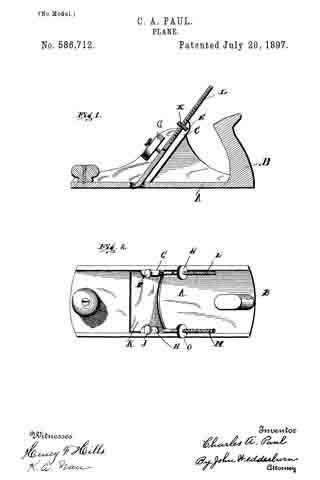

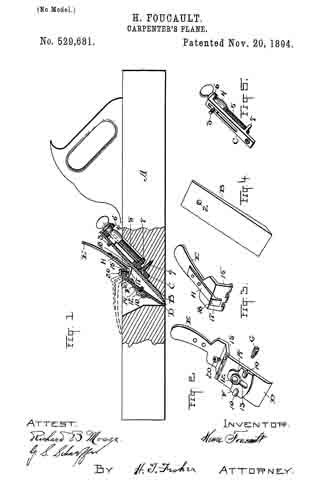

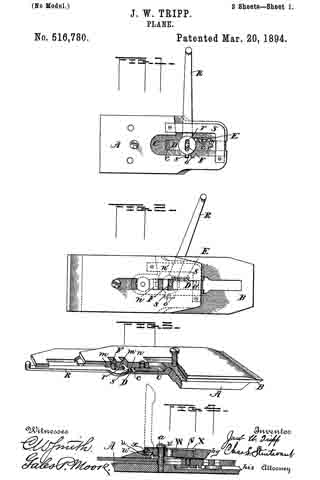

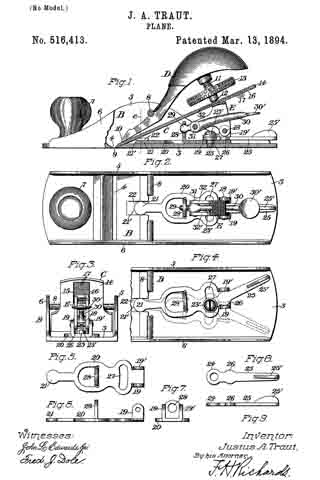

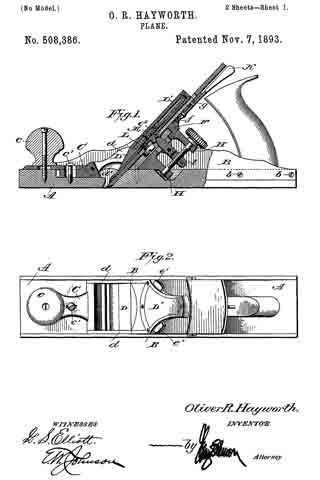

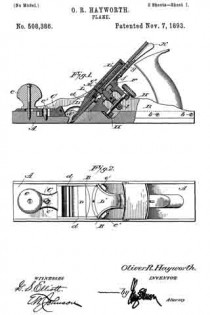

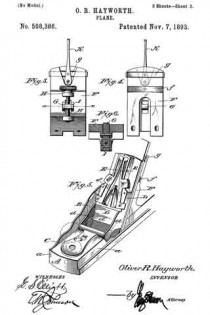

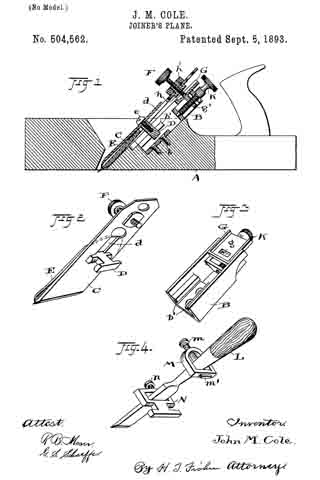

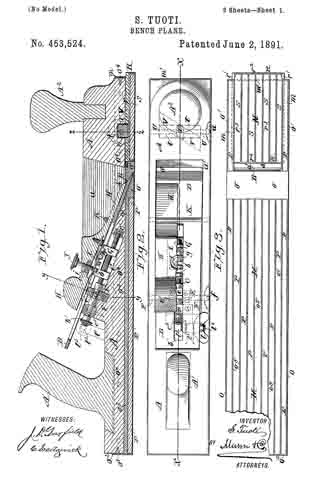

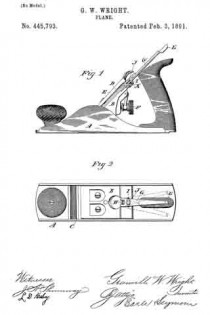

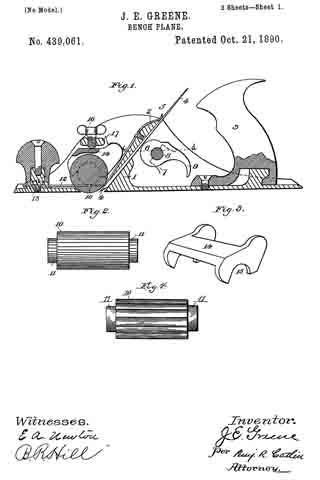

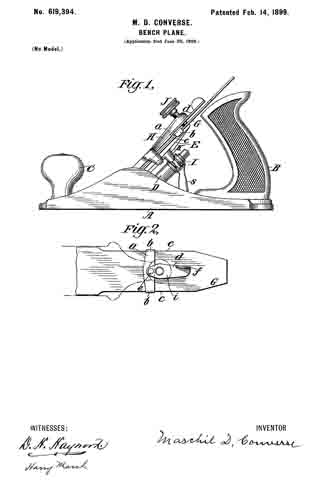

In the drawings, Figure 1 is a side elevation of a bench-plane of the class referred to, showing the construction, application, and disposition of the members in part of my invention. Fig. 2 is a plan view of parts of Fig. 1, showing further the construction, application, and operation of my invention. These figures will presently be more fully described in detail.

Like letters indicate corresponding parts in each figure.

A is a stock, block, or body of a bench-plane of common pattern, having the usual handle B, knob C, and a post D, centrally upon which is mounted a longitudinally-movable inclined plate E, forming a bed for the bit G, above which is another plate H, also longitudinally movable, with a cramp-screw J passing through its outer extremity from the top side, which, together with the said named plates E and H, comprises a screw-cramped clamp for securing the bit G after its adjustment laterally and longitudinally is effected.

I is a worm-screw (provided with a lever s) fastened pivotally to the post D to engage a rack K on the nether bit-clamp plate or bed E, making a known device for adjustment of the bit longitudinally.

a is a metal strap or casting, preferably arranged on the upper side, with ends b b turned right angularly to embrace the outer parallel edges c c of the bit G.

d is a lever operatively pivoted to the center of the strap at e, said lever being fulcrumed on the bearing end of the cramp-screw J in the outer end of the plate H and preferably arranged in a plane above the lateral plane of the bit G. The free end f of this lever d, which is also preferably disposed along the upper side of the bit, is suitably elongated and formed up to insure ease and accuracy of movement in manipulation.

The clamp-plates E and H are so attached to each other and to the post D, which is integral with the stock A, that while each has longitudinal freedom they have substantially no edgewise play. Therefore the fulcrum of the lever d, being on the bearing end of the cramp-screw J at the outer end of the upper bit-clamp plate H, is substantially fixed against lateral movement relatively the plane-stock A. The bit G, on the contrary, is fitted so as to have considerable edgewise freedom at its outer end, while the cutting end is confined against lateral movement, the purposes of which are apparent.

The mechanical operation will be readily understood without further explanation; but it should be specially noted that by a mechanism for lateral adjustment having the disposition of parts with the location and means of fulcrumage herein shown and described the necessity and cost of grooving or piercing of the bits is avoided, so that the same may with advantage be made lighter in consequence, and, moreover, encroachment upon the radial hand-space about the plane-handle is obviated and liability to injury to or accidental disturbance of lateral adjustment of the bit by contact of the operator’s hand wholly overcome. I fulcrum the lever d upon the bearing end of the cramp-screw J for convenience and economy; but it may be fulcrumed by independent means axially coincident to the cramp-screw.

I do not claim a transverse strap or bar, broadly, in a device to engage a plane-bit for its adjustment, such having been used and described in Letters Patent No. 64,790 as early as May 14, 1867; but,

Having described my invention, what I do claim as new, and desire to secure by Letters Patent, is —

1. In a bench-plane, a lever-actuated mechanism adapted to engage the outer edges for lateral adjustment of the bit, having its lever fulcrumed to the bearing end of a cramp-screw in the outer end of the upper bit-clamp plate, the whole constructed and arranged substantially as and for the purposes shown and described.

2. A lever-actuated lateral-adjustment mechanism, having a fulcrum axially coincident to a cramp-screw in the outer end of the upper bit-clamp plate, arranged, relatively of the bit, substantially as and for the purposes shown and described.

3. A lateral-adjustment mechanism, having a fulcrum axially coincident to a cramp-screw in the outer end of an upper bit-clamp plate, arranged, relatively of the bit, substantially as and for the purposes shown and described.

MASCHIL D. CONVERSE.

Witnesses:

PAUL GORHAM,

DWIGHT W. DE MOTTE.