No. 111,890 – Improvement In Joiners’ Planes (George Allen Warren) (1871)

UNITED STATES PATENT OFFICE.

_________________

GEORGE ALLEN WARREN, OF NORTH BRIDGEIVATER, MASSACHUSETTS.

IMPROVEMENT IN JOINERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 111,890, dated February 14, 1871.

_________________

To all whom it may concern:

Be it known that I, GEORGE ALLEN WARREN, of North Bridgewater, of the county of Plymouth, of the State of Massachusetts, have invented a new and useful Improvement in Joiners’ Planes; and I do hereby declare the same to be fully described in the following specification and represented in the accompanying drawings, which show the invention applied to a plane, termed the “Bailey Plane,” it embracing one or more improvements patented by Leonard Bailey.

My invention, or lateral adjuster, as hereinafter described, is to enable a person to effect a lateral movement of a plane iron or bit in either direction, so as to adjust its cutting-edge in parallelism with the bearing-surface ofthe plane-stock.

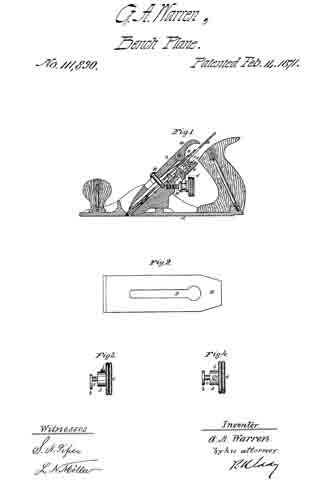

Of the said drawings, Figure 1 denotes a longitudinal section of a plane with my invention applied to it. Fig. 2 is an under side view of the plane-iron or cutter, showing its longitudinal slot, which receives the eccentric of the lateral adjuster. Fig. 3 is a side elevation, and Fig. 4 a top view, of the eccentric and its operative milled head.

In such drawings, A denotes the plane-stock, and B the cutter or plane-iron, they being represented as provided with mechanism for adjusting the cutter longitudinally, and for clamping it down to its bed or bearing-sun face a.

The lateral adjuster is shown at b as consisting of a disk fixed eccentrically on a vertical journal, c, which goes through the bed at or near its upper part, and into the shank d of a milled head, e, the said journal and shank being held in connection by a clamp-screw, f. The eccentric enters the longitudinal slot g of the plane-iron, and has a diameter equal to the width of the slot. On revolving the eccentric more or less the plane-iron may be moved or tilted laterally either way, so as to bring its cutting-edge into proper adjustment with the bearing or lower surface of the plane-stock.

The devices for effecting the longitudinal adjustment of the plane-iron consist of a bent lever, C, and a screw, D, arranged and applied to the said iron and the stock in manner as represented, the devices for clamping the iron to the stock being the headed screw E, the slotted lever F, and the eccentric or cammed lever G, operating against a spring, H, all being as shown, and as commonly made and used in the Bailey plane.

I make no claim to anything, arrangement, or combination of devices as set forth and described in the United States Patent, No.67,398, to Bailey, or in the United States Patent, No. 64,790, to Palmer. My mechanism for effecting lateral adjustment of the bit or plane-iron and the application of such mechanism to the bit, or the arrangement of the adjusting mechanism with the slot of the bit and with the stock of the plane differs materially from anything represented or described in either of such patents, and is particularly advantageous or effective and simple in construction and application.

I claim —

1. The lateral adjuster, as described, as composed of the disk b, the journal c, the socketed shank d, with its clamp-screw and head, as set forth.

2. The arrangement of the said lateral adjuster, as described, with the bed of the stock, and with slot e of the plane-iron, all being substantially as and to operate as explained.

GEORGE ALLEN WARREN.

Witnesses:

R. H. EDDY,

J. R. SNOW.