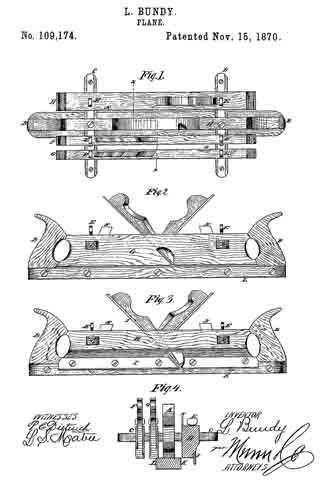

No. 109,174 – Improvement In Planes (Lewis Bundy) (1870)

United States Patent Office.

LEWIS BUNDY, OF MOOER’S FORKS, NEW YORK.

Letters Patent No. 109,174, dated November 15, 1870.

_________________

IMPROVEMENT IN PLANES.

_________________

The Schedule referred to in these Letters Patent and making part of the same.

_________________

To all whom it may concern:

Be it known that I, LEWIS BUNDY, of Mooer’s Forks, in the county of Clinton and State of New York, have invented a new and useful Improvement in Combination Match-Plane and Plow; and I do hereby declare that the following is a full, clear, and exact description thereof; which will enable others skilled in the art to make and use the same, reference being had to the accompanying drawing forming part of this specification.

This invention relates to a new and useful improvement in a combined match-plane and plow, for working in wood, whereby tongues and grooves of variable depth and of variable width of margin may be cut; and

It consists in connecting with a plane-stock two adjustable rabbet-planes and an adjustable grooving-tool or plow, arranged to operate as hereinafter more fully described.

In the accompanying drawing —

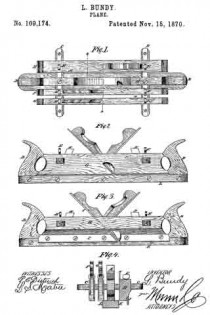

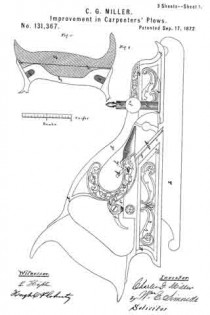

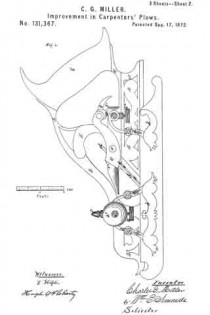

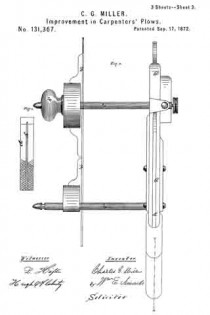

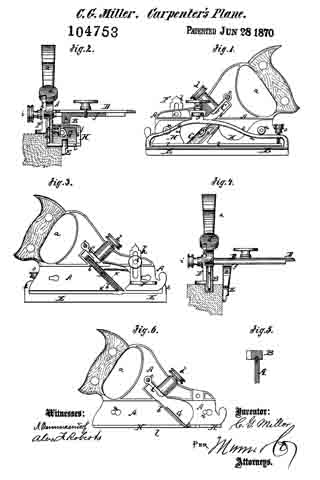

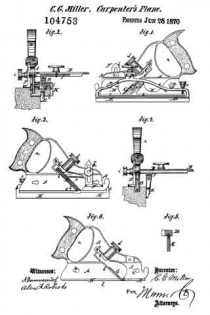

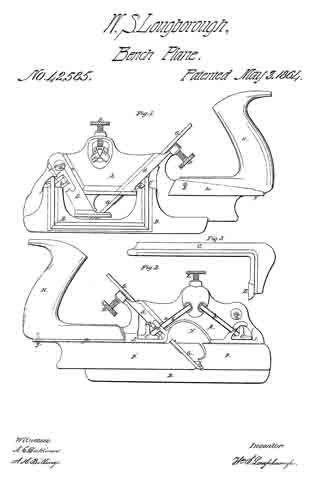

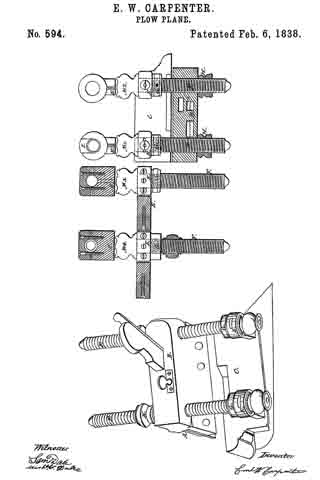

Figure 1 represents a top or plan view of the cornbined tools.

Figure 2 is a view of the rabbeting side of the tool, and showing the gauge on the stock.

Figure 3 is a view of the opposite side, showing the grooving-tool or plow.

Figure 4 is a cross-section of fig. 1, taken on the line x x.

Similar letters ot reference indicate corresponding parts.

A is a central stock, with a handle, B, at each end, the cutting-tools connected therewith being arranged on both sides, so that the stock has to be reversed for cutting a tongue and a groove.

C and D are bars which pass transversely through the stock, (to which they are rigidly attached,) and stand at right angles therewith.

The ends of these bars extend out from either side of the stock, as seen in fig. 1, and the grooving and rabbeting-planes are mortised so as to receive the bars, and are made adjustable thereon, or made to slide to or from the sides of the stock, and are held in any desired position by means of set-screws, marked E.

F and G are two rabbet-planes, which are thus placed upon one side of the stock, and which are adjustable on the bars independently of each other, so as to adapt those planes (or either of them) to other uses than simply cutting tongues for the grooving-plane or plow on the other side of the stock.

H is the plow, which is adjustable to or from the stock, the same as the rabbet-planes.

I is the metallic plate which supports the plow-iron J, and enters the groove as it is cut, as is common with grooving-plows.

K is the gauge on the side of the stock for governing the margin or the distance from the side or angle of the lumber to the groove.

L represents the opposite side of the stock or gauge for the rabbet-planes.

N represents adjustable gauges for governing the depth of cut of the rabbet-planes and the plow.

The inside rabbet-plane F is made to discharge its shaving inward toward the stock, the latter being recessed out, so as to allow of a free discharge.

For tonguing and grooving lumber of varying thicknesses, and for various other purposes in house-joining and other kinds of wood-work, this combined tool will be found ofthe greatest advantage.

Having thus described my invention, I claim as new and desire to secure by Letters Patent —

The plane-stock A, in combination with the bar G, plow H, and rabbet»planes F G, constructed and operating as and for the purpose described.

LEWIS BUNDY.

Witnesses:

CHARLES GALE,

CLINTON P. SHELDON.