No. 102,966 – Improvement In Carpenters’ Planes (Zephaniah Phillips) (1870)

UNITED STATES PATENT OFFICE.

_________________

ZEPHANIAH PHILLIPS, OF DIXON, ILLINOIS.

IMPROVEMENT IN CARPENTERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 102,966, dated May 10, 1870.

_________________

To all whom it may concern:

Be it known that I, Z. PHILLIPS, of Dixon, in the county of Lee and State of Illinois, have invented certain new and useful Improvements in Carpenters’ Planes; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, and to the letters of reference marked thereon, which form a part of this specification.

The nature of my invention consists, first, in so constructing a plane-iron that the bit can be raised and lowered at will by means of a thumb-nut without removing the hand from its natural position; and second, in so constructing a plane-iron that the bit can be tightened or loosened at will by means of a thumb-nut without removing the hand from its natural position.

In order to enable others skilled in the art to which my invention appertains to make and use the same, I will now proceed to describe its construction and operation, referring to the annexed drawings, in which —

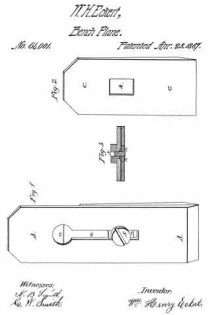

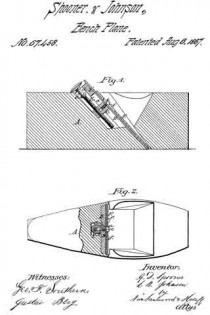

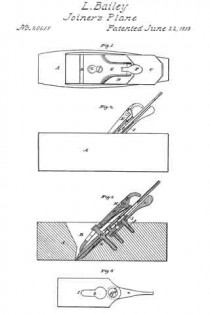

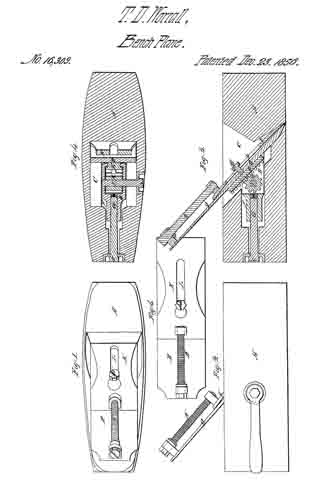

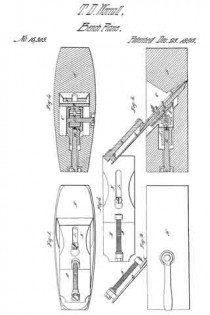

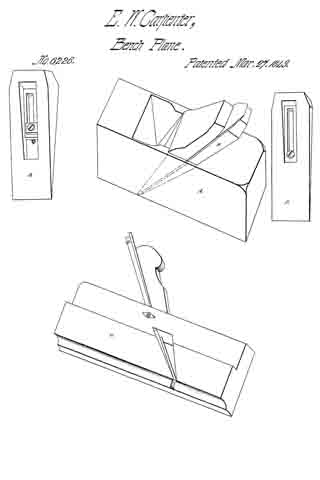

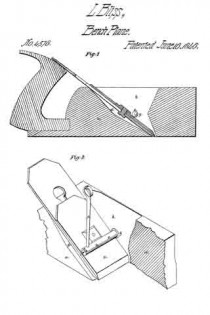

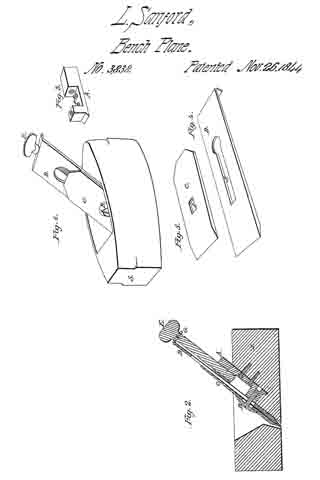

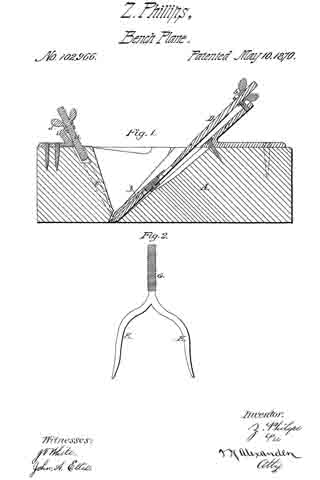

Figure 1 is a longitudinal vertical section of my planing-iron, and Fig. 2 is a front view of the fork which tightens the bit.

A represents the usual wood part or stock of a plane, having a V-shaped aperture for the insertion of the bit B. Immediately in rear of this aperture, on top of the stock A, is secured an inclined rest, C, provided with a forked projection, a, to hold the thumb-nut on the bit.

The bit B is provided at its upper end with a shank, D, having screw-threads, and a thumb-nut, b, placed on the same. The thumb-nut b is grooved, so as to pass into and be held by the forked projection a.

In small planes the rest C, with the nut D, may be used as a handle, but in larger planes the handle would be placed close to the said rest, so that the operator can, without removing his hand from the handle, turn the thumb-nut b in either direction, and consequently raise or lower the bit.

The bit B is tightened or loosened at will by the following means: A fork, E, provided with a screw-shank, G, is passed down through an inclined slot in the stock A in front of the aperture through which the bit is passed, the ends of the fork resting upon the bit, as shown in Fig. 1. On the screw-shank G is placed a thumb-nut, d, which is grooved and held in a forked rest, e, on the stock. By turning the thumb-nut d in one direction the fork E will be lowered, so as to bear against the bit and tighten the same, and by turning said nut in the opposite direction the fork is raised and the bit loosened, which all can be accomplished without the operator having to remove his left hand from the usual position on the plane.

Having thus fully described my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. The fork E, when constructed and arranged to operate in the manner and for the purpose set forth.

2. In combination with the fork E, bit B, when constructed and arranged to operate as and for the purpose described.

In testimony that I claim the foregoing as my own I affix my signature in presence of two witnesses.

ZEPHANIAH PHILLIPS.

Witnesses:

GEO. CURKENDALL,

D. H. LAW.